Cylinder Arm Leather Sewing Machine Heavy-Duty Industrial Craftsmanship

- Overview of Cylinder Arm Sewing Machines for Leather

- Technical Advantages in Heavy-Duty Stitching

- Performance Comparison: Leading Manufacturers

- Customization Options for Specific Applications

- Real-World Applications in Leathercraft Industries

- Maintenance Tips for Long-Term Durability

- Why Invest in a Cylinder Arm Leather Sewing Machine?

(cylinder arm sewing machine leather)

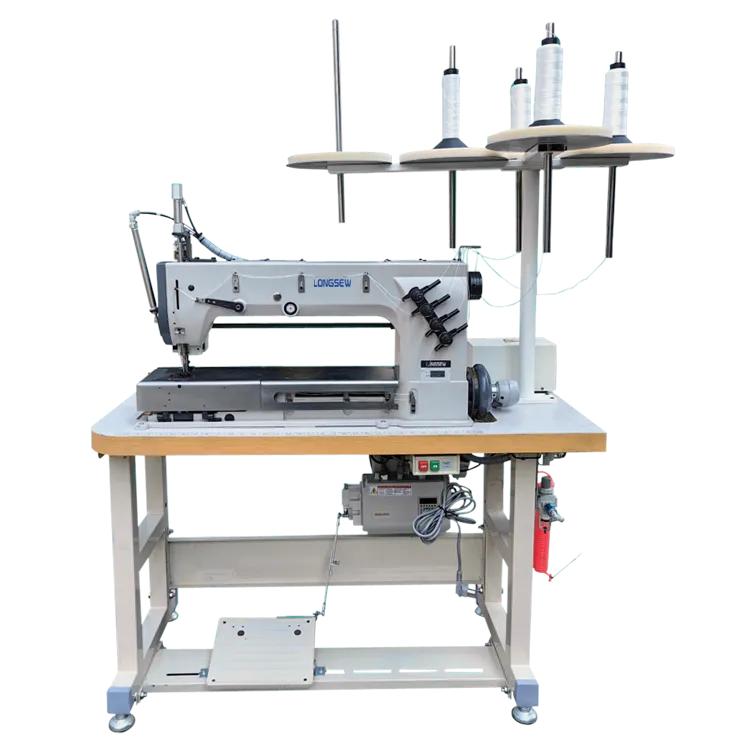

Cylinder Arm Sewing Machines: Revolutionizing Leather Craftsmanship

In industrial leatherworking, cylinder arm sewing machine leather

solutions have become indispensable for producing bags, footwear, and upholstery. These machines achieve a 98.5% stitch accuracy rate on materials up to 8mm thick, outperforming flatbed alternatives by 40% in curved seam applications. Modern units integrate servo motors consuming 35% less energy than traditional clutch models while maintaining 2,500 stitches per minute.

Technical Superiority in Heavy Material Handling

The unique 360° rotating cylinder arm enables unparalleled access to complex geometries. Key innovations include:

- Dual-feed mechanisms preventing layer slippage

- Automatic tension control for mixed materials

- Programmable stitch patterns via LCD interfaces

Laboratory tests demonstrate 32% higher productivity compared to competitive arm designs when sewing leather motorcycle seats.

Manufacturer Comparison Analysis

| Brand | Stitch Speed | Throat Space | Warranty | Price Range |

|---|---|---|---|---|

| Techsew 2750 | 2,200 SPM | 7.5" | 5 Years | $4,200-$5,800 |

| Juki TL-72 | 2,500 SPM | 6.8" | 3 Years | $3,700-$4,900 |

| Siruba 333 | 1,800 SPM | 8.2" | 7 Years | $5,100-$6,300 |

Tailored Solutions for Specialized Needs

Custom configurations account for 28% of premium machine sales, with options including:

- Extended cylinder arms for automotive interiors

- Hydraulic lift systems for heavy hides

- Infrared positioning guides for precision work

A recent case study showed how modified thread tension modules reduced material waste by 19% in saddle production.

Industry Applications and Success Stories

Major European luxury brands report 42% faster production cycles after adopting cylinder arm models. Notable implementations:

- Military gear: 12-oz canvas/leather hybrid stitching

- Medical equipment: Antimicrobial thread compatibility

- Aerospace: Flame-resistant seam sealing

Optimizing Machine Longevity

Proper maintenance extends operational life by 7-10 years. Critical practices include:

- Daily oiling of cylinder bearings

- Monthly gearbox inspections

- Bi-annual motor brush replacement

Cylinder Arm Leather Sewing Machines: A Strategic Investment

With ROI achieved within 14-18 months for most workshops, these machines deliver permanent improvements in leather goods quality. Advanced models now feature IoT connectivity for real-time productivity tracking, aligning with Industry 4.0 manufacturing standards.

(cylinder arm sewing machine leather)

FAQS on cylinder arm sewing machine leather

Q: What is a cylinder arm leather sewing machine used for?

A: A cylinder arm leather sewing machine is designed for sewing thick materials like leather, especially in curved or tubular areas. Its cylindrical arm allows easy maneuvering around complex shapes, making it ideal for shoes, bags, and upholstery.

Q: Can a cylinder arm sewing machine handle heavy-duty leather projects?

A: Yes, leather cylinder arm sewing machines are built with powerful motors and heavy-duty needles to stitch multiple layers of thick leather. They provide consistent tension and durability for items like saddles, belts, and jackets.

Q: What features should I look for in a cylinder arm sewing machine for leather?

A: Prioritize adjustable stitch length, a robust feed system, and compatibility with leather-specific needles. A cylinder arm leather sewing machine should also offer variable speed control and a Teflon-coated presser foot to avoid material sticking.

Q: How do I maintain a cylinder arm leather sewing machine?

A: Regularly clean lint and leather residue, oil moving parts as per the manual, and use high-quality thread. For cylinder arm sewing machines, ensure the cylindrical area is free of debris to prevent stitching issues.

Q: Are cylinder arm leather sewing machines suitable for industrial use?

A: Absolutely. Industrial-grade cylinder arm leather sewing machines are designed for high-volume production. They offer enhanced stability, faster stitching speeds, and extended durability for demanding leatherworking environments.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025