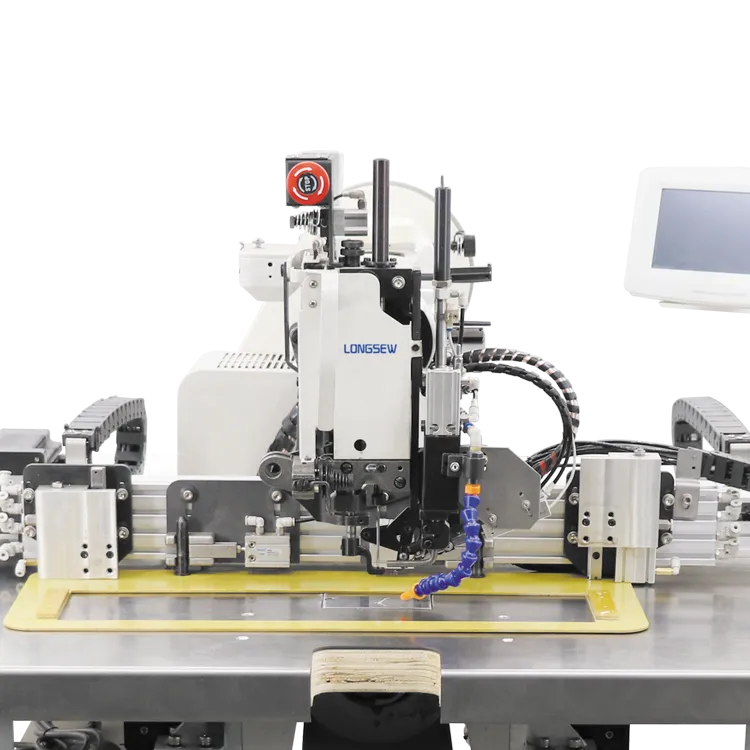

آلة الخياطة المحوسبة الثقيلة

A heavy-duty computerized pattern sewing machine is an advanced sewing machine designed for industrial applications that require precise, repetitive stitching patterns on tough

materials. This machine combines the strength and durability of a heavy-duty sewing machine with the precision and versatility of computerized controls, allowing users to program and execute complex stitching patterns with ease. It is ideal for large-scale production environments, such as in the automotive, upholstery, and garment industries.

What Are The Benefits Of A Computerized Pattern Sewing Machine?

The main benefits include precision, consistency, and efficiency. The computerized system allows for the programming of complex patterns, which can be repeated accurately across multiple pieces. This ensures uniformity in production, which is crucial for industrial applications. The machine's heavy-duty build means it can handle thick fabrics and multiple layers without compromising stitch quality, making it suitable for demanding tasks like stitching leather, canvas, and other tough materials.

What Types Of Materials Can This Machine Handle?

A heavy-duty computerized pattern sewing machine is designed to handle a wide range of materials, including leather, canvas, denim, and other thick or heavy fabrics. It can also manage multiple layers of fabric, which is essential in industries like upholstery, automotive interiors, and heavy garment manufacturing.