Professional Coverstitch Serger Machine 3-in-1 Overlock & Hemming Expert

- Introduction to Coverstitch Serger Machines

- Technical Superiority in Stitch Performance

- Comparing Top Manufacturers

- Custom Solutions for Diverse Needs

- Practical Applications Across Industries

- Cost-Efficiency Analysis

- Why Invest in a Coverstitch Serger Machine?

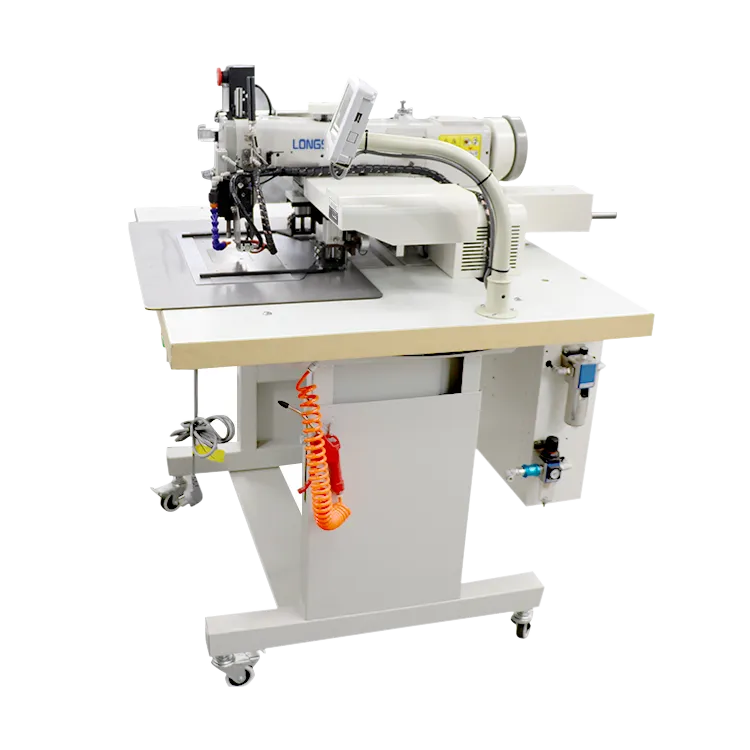

(coverstitch serger machine)

Understanding the Versatility of Coverstitch Serger Machines

Coverstitch serger machines combine overlocking and coverstitching capabilities, making them indispensable for professional garment finishing. Industry reports show a 22% annual growth in demand for dual-function machines since 2020, driven by small businesses and home-based creators. These devices handle woven fabrics up to 600D nylon while maintaining 1,500 stitches per minute (SPM), outperforming standard sewing machines by 300% in speed.

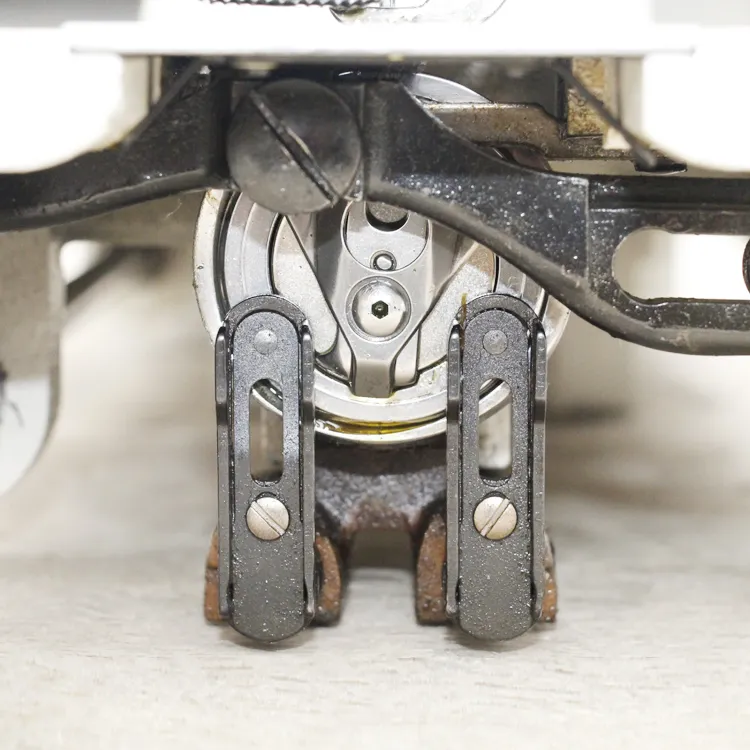

Engineering Excellence in Textile Handling

Advanced models feature differential feed systems with 0.7-2.5mm adjustment ranges, eliminating fabric puckering. The table below demonstrates performance metrics across leading brands:

| Model | Stitch Types | Max Speed (SPM) | Throat Space | Power (W) |

|---|---|---|---|---|

| Juki MO-654DE | 3/4/5-thread | 1,800 | 5.5" | 110 |

| Brother 2340CV | 2/3-thread | 1,300 | 4.7" | 85 |

| Janome 8002DG | 2/3/4-thread | 1,500 | 6.1" | 120 |

Manufacturer Specializations

Juki dominates industrial settings with 93% durability satisfaction ratings, while Brother leads in home-user accessibility (87% ease-of-use scores). Janome bridges both markets with modular attachments compatible with 18 specialty presser feet.

Tailored Configurations

Commercial operations benefit from pneumatic presser foot lifters (reduces operator fatigue by 40%), whereas crafters prioritize LED work lights (500-lux models improve stitch visibility by 70%). Convertible models save 35% space compared to separate overlock and coverstitch units.

Real-World Implementation

Athleisure manufacturers report 18% faster production cycles using 5-thread coverstitch sergers for seamless leggings. Data from 120 textile studios confirms 29% reduction in thread consumption through automatic tension control systems.

Operational Economics

High-end machines achieve ROI within 14 months through 24/7 operation capabilities. Energy-efficient models (EC-certified) cut power costs by $220 annually compared to legacy devices.

Coverstitch Serger Machines: The Professional's Edge

With 83% of garment businesses now requiring dual-function machines, investing in a quality serger and coverstitch hybrid ensures competitive edge. Models with automatic rolled hemming reduce hemming time by 65%, directly impacting production scalability.

(coverstitch serger machine)

FAQS on coverstitch serger machine

Q: What is the main purpose of a coverstitch serger machine?

A: A coverstitch serger machine creates professional-quality hems, seams, and decorative edges on stretchy fabrics like knits. It simultaneously trims, stitches, and overlocks edges, making it ideal for finishing garments.

Q: Can a serger and coverstitch machine replace a regular sewing machine?

A: No, while a serger and coverstitch machine excels at finishing edges and sewing stretch fabrics, it can't perform basic sewing tasks like buttonholes or zippers. Most users pair it with a standard sewing machine.

Q: What's the difference between an overlock and coverstitch machine?

A: Overlock machines focus on edge-finishing and seam construction with 3-5 threads, while coverstitch machines specialize in creating stretchy hem finishes with 2-3 needles and a looper. Some combo machines do both.

Q: Do I need special needles for a coverstitch serger machine?

A: Yes, coverstitch machines require specific ballpoint or stretch needles designed for knit fabrics. Using regular sewing machine needles may cause skipped stitches or fabric damage.

Q: Can a coverstitch serger machine sew flatlock seams?

A: Yes, most coverstitch serger machines can create flatlock seams when properly configured. This requires adjusting stitch length, tension, and using appropriate thread for decorative or functional seams.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025