Jan . 09, 2025 11:48

Back to list

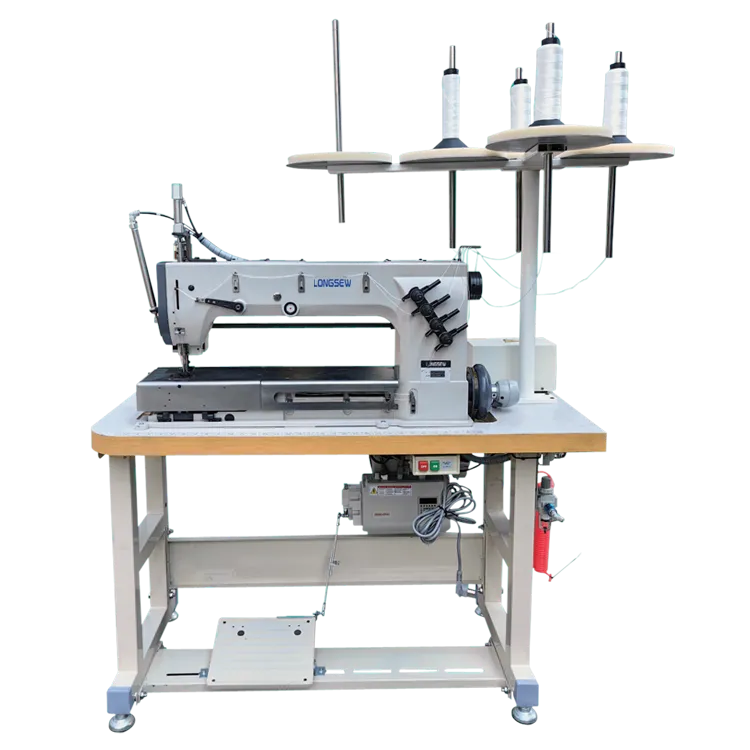

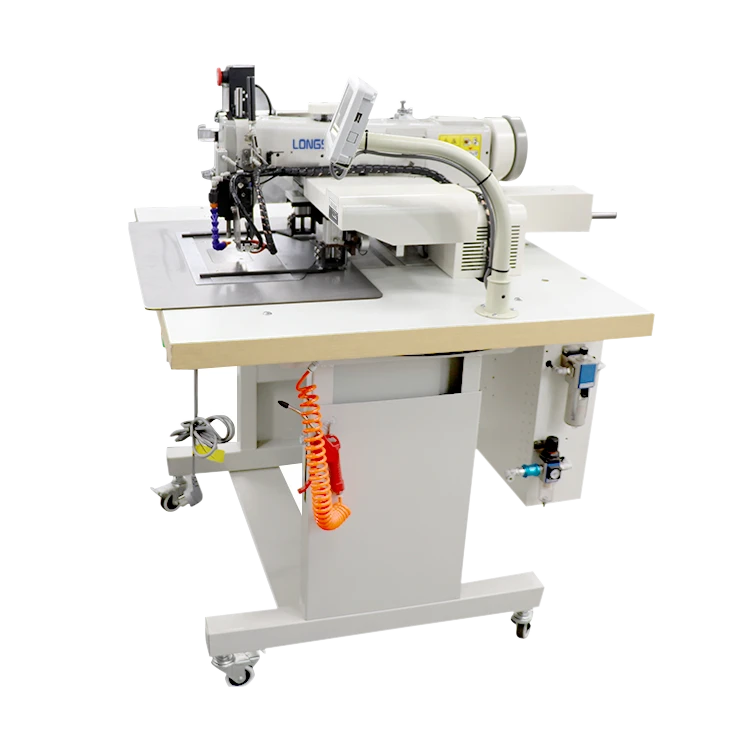

PP Woven Bag / Big Bag Single Needle 2 Threads Chainstitch Sewing Machine Head DN-2HS / DN-2LHS

When one considers the intricate world of industrial-grade sewing machinery, the jumbo bag sewing machine stands as a pivotal innovation for packaging and logistical industries. Often, companies that need to transport powders, granules, or even large solid pieces depend on jumbo bags for efficient and safe travel. In such scenarios, a reliable and high-quality jumbo bag sewing machine becomes not only an asset but a necessity.

Authoritativeness in manufacturing is often linked with brands that have established a reputation for producing resilient and efficient machinery. Companies such as Union Special, Fischbein, and Newlong are recognized leaders in this field. Their machines are often cited for their technological advancements and robust construction, which customers trust when their business depends on it. While various brands offer different features, authority in this niche market remains closely tied to reliability and after-sales support—critical elements for establishing longstanding customer trust. In terms of trustworthiness, purchasing managers and production engineers often prioritize machines that deliver on their promise of durability and serviceability. A smart investment in a jumbo bag sewing machine considers not only the initial purchase price but also the long-term costs, including maintenance and potential downtime. Thus, the reliability of a manufacturer’s customer service, availability of parts, and the ease of repair are significant considerations. A trustworthy brand will not just sell a product but will offer a partnership in ensuring that the machine serves its purpose over years, if not decades. In conclusion, a jumbo bag sewing machine becomes the backbone of operations for businesses looking to efficiently and securely handle bulk packaging. The interplay of real-world user experience, expert-driven technological advancements, and the trust built by authoritative brands create an ecosystem that promotes sustained industrial productivity. For businesses, choosing the right jumbo bag sewing machine is less about simple machinery acquisition and more about ensuring a reliable partner in growth and success.

Authoritativeness in manufacturing is often linked with brands that have established a reputation for producing resilient and efficient machinery. Companies such as Union Special, Fischbein, and Newlong are recognized leaders in this field. Their machines are often cited for their technological advancements and robust construction, which customers trust when their business depends on it. While various brands offer different features, authority in this niche market remains closely tied to reliability and after-sales support—critical elements for establishing longstanding customer trust. In terms of trustworthiness, purchasing managers and production engineers often prioritize machines that deliver on their promise of durability and serviceability. A smart investment in a jumbo bag sewing machine considers not only the initial purchase price but also the long-term costs, including maintenance and potential downtime. Thus, the reliability of a manufacturer’s customer service, availability of parts, and the ease of repair are significant considerations. A trustworthy brand will not just sell a product but will offer a partnership in ensuring that the machine serves its purpose over years, if not decades. In conclusion, a jumbo bag sewing machine becomes the backbone of operations for businesses looking to efficiently and securely handle bulk packaging. The interplay of real-world user experience, expert-driven technological advancements, and the trust built by authoritative brands create an ecosystem that promotes sustained industrial productivity. For businesses, choosing the right jumbo bag sewing machine is less about simple machinery acquisition and more about ensuring a reliable partner in growth and success.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025