Jan . 09, 2025 11:46

Back to list

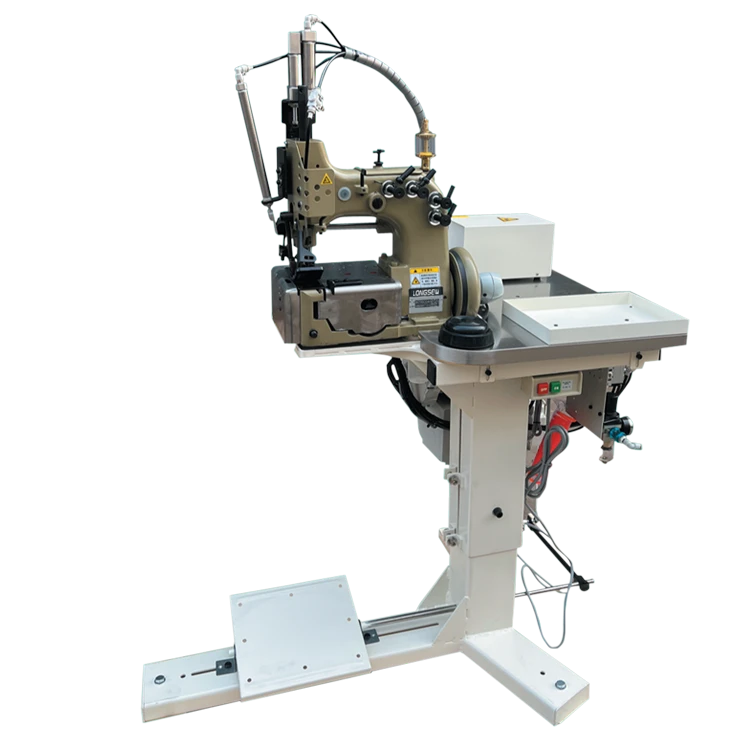

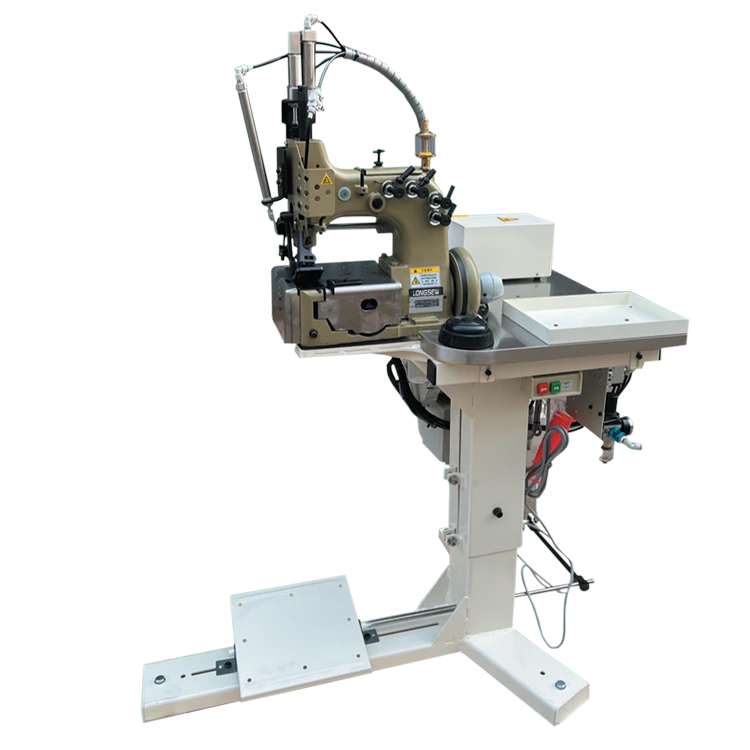

FIBC Bag / Jumbo Bag / Big Bag Double Needles Chain Stitch Sewing Machine 80700C/ 80700CD / 80700CD4H

In the evolving world of industrial manufacturing, the significance of finding the right equipment cannot be overstated, especially when it pertains to FIBC sewing machines. For businesses specializing in the production of Flexible Intermediate Bulk Containers (FIBCs), having the right sewing machine ensures the production process is seamless, efficient, and meets high-quality standards. This article explores the crucial aspects of selecting and utilizing FIBC sewing machines, combining real-world experience with authoritative insights from industry experts.

When evaluating an FIBC sewing machine's authoritativeness, it's essential to consider the manufacturer's reputation and the technological advancements incorporated into their products. Renowned manufacturers consistently update their sewing machines with innovative features such as automated threading and digital interfaces that monitor performance metrics in real-time. These advancements not only enhance efficiency but also provide operators with the data needed to make informed adjustments, ensuring each bag meets strict quality assurance standards. Trustworthiness in the context of FIBC sewing machines involves looking into customer reviews and case studies that highlight the reliability and performance of a given brand or model. A trustworthy sewing machine should demonstrate a track record of exceptional performance, with minimal maintenance issues and robust support from the manufacturer. Companies often share testimonials showcasing how the right sewing machine has enhanced their production efficiency and product quality, offering potential buyers peace of mind and confidence in their investment. Ultimately, the journey to selecting and maximizing the use of an FIBC sewing machine is an amalgam of experience, expertise, authoritative insights, and trustworthiness. Businesses that prioritize these elements often find themselves at the forefront of the industry, delivering high-quality bulk bags that meet the rigorous demands of global markets. By focusing on these key aspects, companies can enhance their operational efficiency, foster innovation, and drive their business towards sustainable success in the competitive landscape of industrial manufacturing. The right FIBC sewing machine is not merely a tool; it's a pivotal part of the production ecosystem that underpins the success and reputation of bag manufacturing enterprises worldwide.

When evaluating an FIBC sewing machine's authoritativeness, it's essential to consider the manufacturer's reputation and the technological advancements incorporated into their products. Renowned manufacturers consistently update their sewing machines with innovative features such as automated threading and digital interfaces that monitor performance metrics in real-time. These advancements not only enhance efficiency but also provide operators with the data needed to make informed adjustments, ensuring each bag meets strict quality assurance standards. Trustworthiness in the context of FIBC sewing machines involves looking into customer reviews and case studies that highlight the reliability and performance of a given brand or model. A trustworthy sewing machine should demonstrate a track record of exceptional performance, with minimal maintenance issues and robust support from the manufacturer. Companies often share testimonials showcasing how the right sewing machine has enhanced their production efficiency and product quality, offering potential buyers peace of mind and confidence in their investment. Ultimately, the journey to selecting and maximizing the use of an FIBC sewing machine is an amalgam of experience, expertise, authoritative insights, and trustworthiness. Businesses that prioritize these elements often find themselves at the forefront of the industry, delivering high-quality bulk bags that meet the rigorous demands of global markets. By focusing on these key aspects, companies can enhance their operational efficiency, foster innovation, and drive their business towards sustainable success in the competitive landscape of industrial manufacturing. The right FIBC sewing machine is not merely a tool; it's a pivotal part of the production ecosystem that underpins the success and reputation of bag manufacturing enterprises worldwide.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025