Jan . 09, 2025 11:43

Back to list

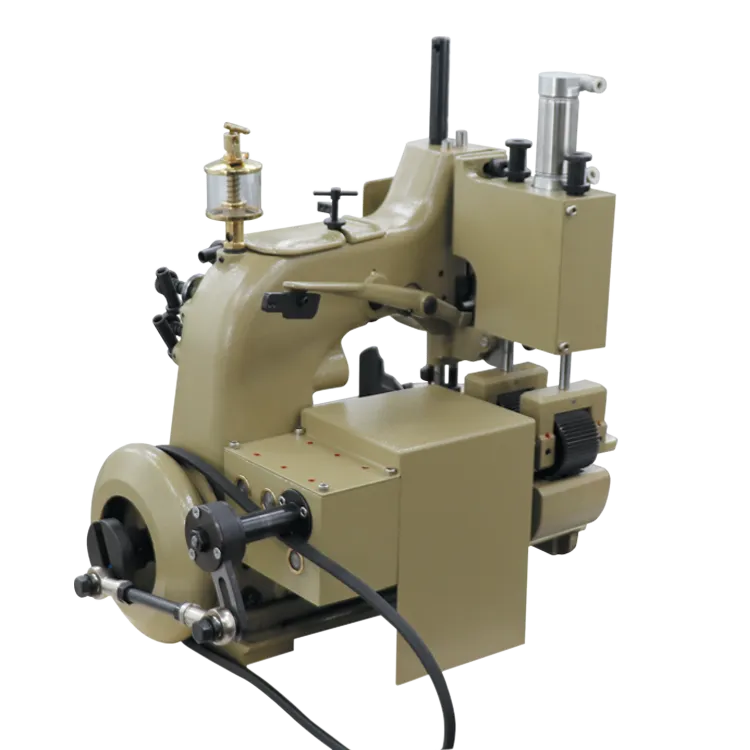

jumbo bag stitching machine

Jumbo bag stitching machines have emerged as indispensable tools in the packaging industry, where efficiency, precision, and reliability are paramount. These machines are engineered to meet the diverse needs of businesses that require high-quality stitching of large capacity bags, commonly known as FIBCs (Flexible Intermediate Bulk Containers).

Authoritativeness in the market is often associated with brands that have built a strong reputation over the years. Leading manufacturers of jumbo bag stitching machines are known not just for their cutting-edge technology, but also for their commitment to after-sales support. Companies with authoritative standing typically offer extensive warranties, comprehensive training programs, and readily available spare parts. This support system reassures clients that the machines will maintain peak performance over extended periods, thereby boosting the buyer's confidence in the investment. Trustworthiness is further established through stringent quality control measures during the production process of jumbo bag stitching machines. Manufacturers often adhere to international standards and certifications, which serve as a testament to the product's reliability. Client testimonials and case studies frequently highlight how these machines have consistently delivered high-quality stitching results, even under challenging operational conditions. The transparency in manufacturing processes and the evidence of consistent performance work in tandem to build trust among potential buyers. In conclusion, the jumbo bag stitching machine is a vital asset for any business focused on bulk packaging. Its role in streamlining operations, coupled with robust construction and superior technology, underscores its value in the industry. By aligning machine quality and service with the pillars of experience, expertise, authoritativeness, and trustworthiness, manufacturers ensure that these machines remain at the forefront of packaging solutions, meeting and exceeding industry expectations.

Authoritativeness in the market is often associated with brands that have built a strong reputation over the years. Leading manufacturers of jumbo bag stitching machines are known not just for their cutting-edge technology, but also for their commitment to after-sales support. Companies with authoritative standing typically offer extensive warranties, comprehensive training programs, and readily available spare parts. This support system reassures clients that the machines will maintain peak performance over extended periods, thereby boosting the buyer's confidence in the investment. Trustworthiness is further established through stringent quality control measures during the production process of jumbo bag stitching machines. Manufacturers often adhere to international standards and certifications, which serve as a testament to the product's reliability. Client testimonials and case studies frequently highlight how these machines have consistently delivered high-quality stitching results, even under challenging operational conditions. The transparency in manufacturing processes and the evidence of consistent performance work in tandem to build trust among potential buyers. In conclusion, the jumbo bag stitching machine is a vital asset for any business focused on bulk packaging. Its role in streamlining operations, coupled with robust construction and superior technology, underscores its value in the industry. By aligning machine quality and service with the pillars of experience, expertise, authoritativeness, and trustworthiness, manufacturers ensure that these machines remain at the forefront of packaging solutions, meeting and exceeding industry expectations.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025