Jan . 09, 2025 11:50

Back to list

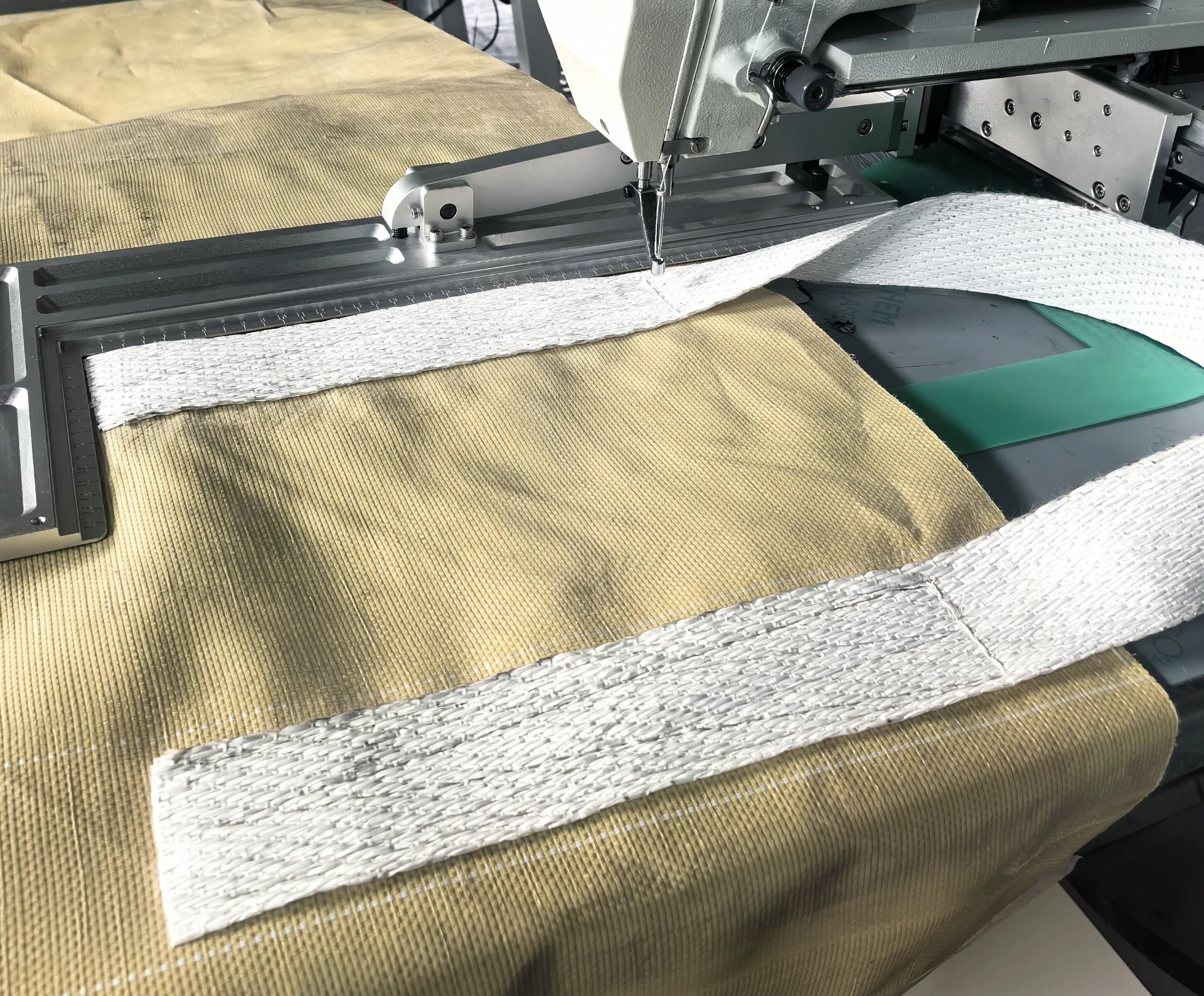

FIBC Bag / Jumbo Bag / Big Bag Automatic Computerized Pattern Sewing Machine For Bulk Bag Loop Ring or Lifting Belt LS200-5020

The demand for efficiency and precision in the textile and packaging industries has driven the innovation and adoption of advanced machinery. Among these, the big bag sewing machine stands out as a pivotal tool, thanks to its capacity to handle large volumes and offer impeccable sewing quality. This asset in production not only optimizes time but also heightens the overall quality of products.

Authoritativeness in the realm of big bag sewing machines is supported by endorsements from various industry leaders who rely on the durability and efficiency these machines provide. Testimonials and case studies from businesses that have integrated big bag sewing machines into their production lines often highlight improvements in throughput and reductions in downtime. Invested brands offer comprehensive training programs and certifications for machine operators, which further underscores the importance and reliability of these machines in professional settings. Trustworthiness in the technological scope of big bag sewing machines is significantly bolstered by adherence to international safety and quality standards. Machines are regularly subjected to rigorous testing to ensure that they meet industry benchmarks, providing users with peace of mind regarding their investment. Reliable manufacturers offer extensive warranties and robust customer support networks, assuring clients that they will receive assistance and maintenance guidance as needed. Innovation in big bag sewing machines continues to evolve, with manufacturers focusing on sustainability and energy efficiency. Future advancements may see increased integration with IoT systems, allowing for real-time monitoring and adjustments, which could revolutionize how operators interact with the machines and manage their production lines. In conclusion, the big bag sewing machine is an indispensable component in achieving efficiency and quality in large-scale production environments. Its advanced features, paired with the user-friendly operation, make it a trusted choice for industries looking to optimize their sewing processes while maintaining high standards of product integrity.

Authoritativeness in the realm of big bag sewing machines is supported by endorsements from various industry leaders who rely on the durability and efficiency these machines provide. Testimonials and case studies from businesses that have integrated big bag sewing machines into their production lines often highlight improvements in throughput and reductions in downtime. Invested brands offer comprehensive training programs and certifications for machine operators, which further underscores the importance and reliability of these machines in professional settings. Trustworthiness in the technological scope of big bag sewing machines is significantly bolstered by adherence to international safety and quality standards. Machines are regularly subjected to rigorous testing to ensure that they meet industry benchmarks, providing users with peace of mind regarding their investment. Reliable manufacturers offer extensive warranties and robust customer support networks, assuring clients that they will receive assistance and maintenance guidance as needed. Innovation in big bag sewing machines continues to evolve, with manufacturers focusing on sustainability and energy efficiency. Future advancements may see increased integration with IoT systems, allowing for real-time monitoring and adjustments, which could revolutionize how operators interact with the machines and manage their production lines. In conclusion, the big bag sewing machine is an indispensable component in achieving efficiency and quality in large-scale production environments. Its advanced features, paired with the user-friendly operation, make it a trusted choice for industries looking to optimize their sewing processes while maintaining high standards of product integrity.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025