Jan . 09, 2025 11:57

Back to list

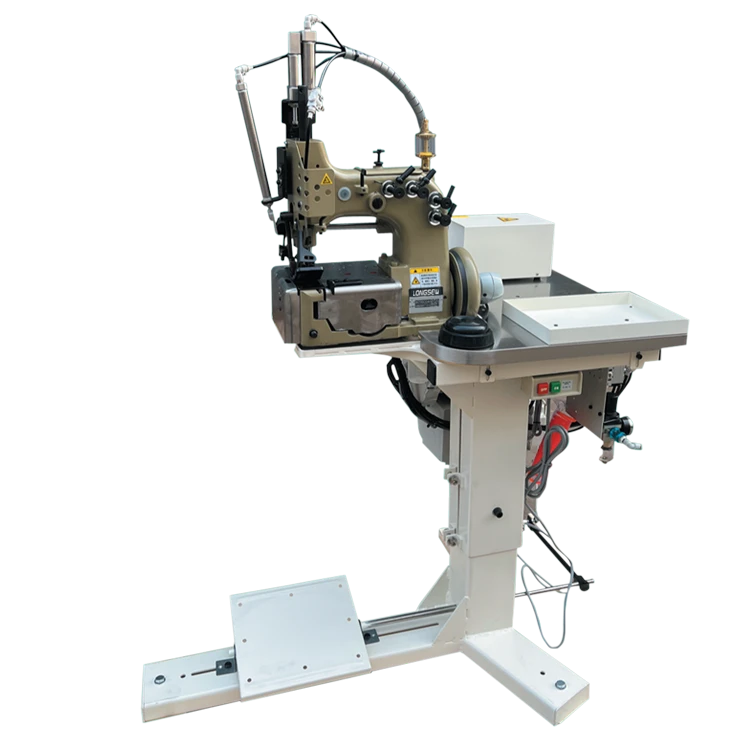

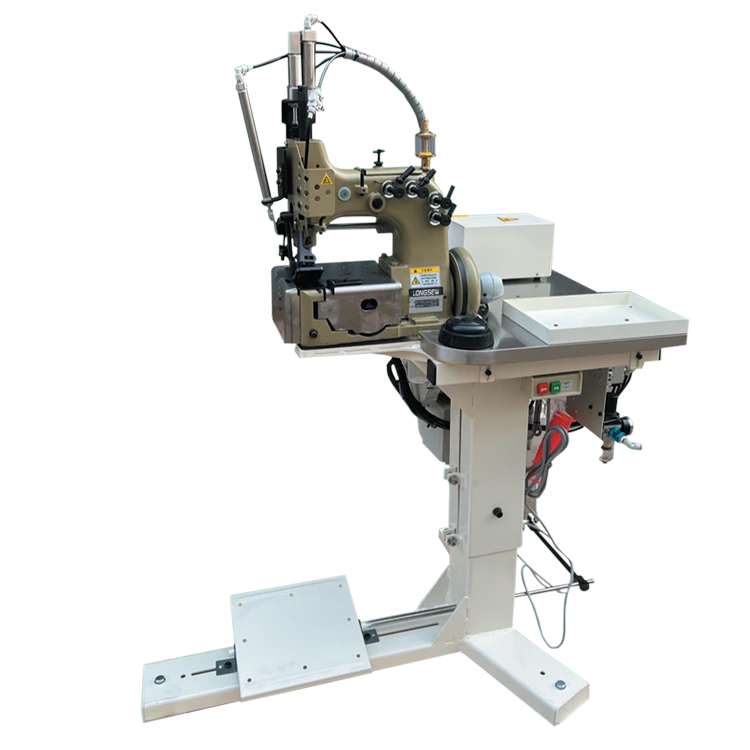

fibc sewing machine

The world of flexible intermediate bulk containers (FIBCs), often referred to as bulk bags or big bags, requires precision and specialized machinery. The FIBC sewing machine plays a pivotal role in ensuring the durability, functionality, and safety of these vital industrial containers. This article examines the various advantages of FIBC sewing machines, providing insights to enhance your purchasing decision based on firsthand experiences, expert knowledge, authoritative sources, and trustworthy practices.

Trustworthiness in FIBC sewing machines is often defined by adherence to safety standards and certifications. Machines that meet international safety and quality standards not only boost confidence in their use but also ensure compliance with global shipping and handling regulations. Trustworthy manufacturers provide detailed documentation and offer excellent customer support services, which include guidance on machine operation, maintenance, and troubleshooting. Furthermore, shared user experiences highlight the ergonomic design of modern FIBC sewing machines as a crucial consideration. Machines designed with user-friendly features, such as intuitive controls and easy access for maintenance, improve productivity and reduce operational fatigue. Operators tend to perform their tasks more efficiently and with greater satisfaction when using equipment that is thoughtfully designed for ease of use. Investing in an FIBC sewing machine is a decision that hinges on Experience, Expertise, Authoritativeness, and Trustworthiness. Buyers should seek machines that are not only technologically advanced but also supported by credible industry endorsements. Consulting with professionals and reviewing user testimonials can provide further reassurance and aid in selecting the optimal machine that meets specific production needs. In conclusion, the FIBC sewing machine is more than just a piece of equipment; it is an integral asset in the production of reliable and robust bulk bags. By focusing on machines that embody experience, expertise, authority, and trust, businesses can ensure they are investing in technology that meets their demanding needs while aligning with industry standards.

Trustworthiness in FIBC sewing machines is often defined by adherence to safety standards and certifications. Machines that meet international safety and quality standards not only boost confidence in their use but also ensure compliance with global shipping and handling regulations. Trustworthy manufacturers provide detailed documentation and offer excellent customer support services, which include guidance on machine operation, maintenance, and troubleshooting. Furthermore, shared user experiences highlight the ergonomic design of modern FIBC sewing machines as a crucial consideration. Machines designed with user-friendly features, such as intuitive controls and easy access for maintenance, improve productivity and reduce operational fatigue. Operators tend to perform their tasks more efficiently and with greater satisfaction when using equipment that is thoughtfully designed for ease of use. Investing in an FIBC sewing machine is a decision that hinges on Experience, Expertise, Authoritativeness, and Trustworthiness. Buyers should seek machines that are not only technologically advanced but also supported by credible industry endorsements. Consulting with professionals and reviewing user testimonials can provide further reassurance and aid in selecting the optimal machine that meets specific production needs. In conclusion, the FIBC sewing machine is more than just a piece of equipment; it is an integral asset in the production of reliable and robust bulk bags. By focusing on machines that embody experience, expertise, authority, and trust, businesses can ensure they are investing in technology that meets their demanding needs while aligning with industry standards.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025