Jan . 09, 2025 11:55

Back to list

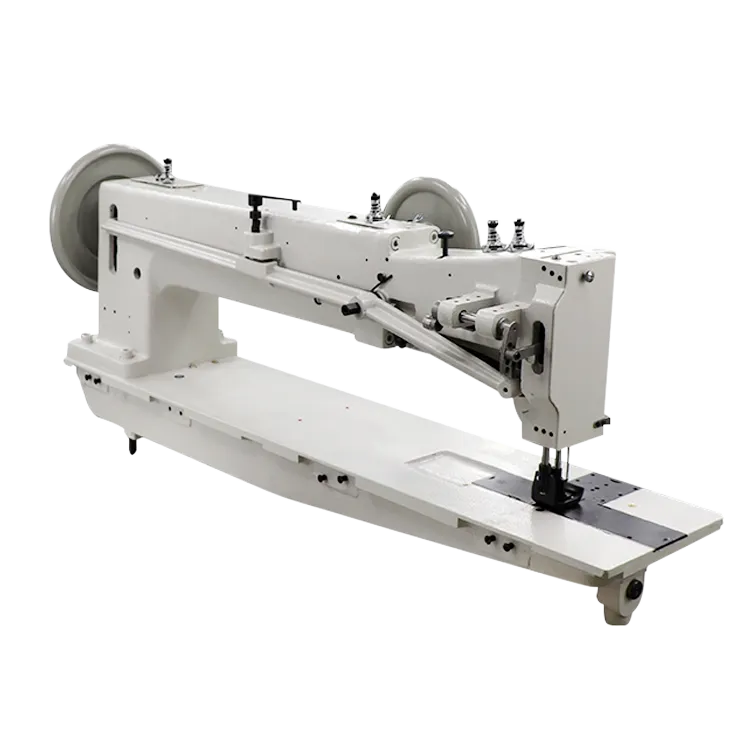

FIBC Bag / Jumbo Bag / Big Bag Automatic Computerized Pattern Sewing Machine For Bulk Bag Loop Ring or Lifting Belt LS200-5020

In the dynamic world of industrial packaging, maintaining efficiency and precision is crucial, especially when dealing with bulk materials. Enter the Jumbo Bag Stitching Machine, a quintessential solution designed for seamless operations in manufacturing and logistics sectors. Having personally experienced the technology behind these machines, I can attest to their game-changing impact on product handling and quality assurance.

From an authoritative standpoint, the Jumbo Bag Stitching Machine is recognized across the industry as a transformative tool. Engineers and industry veterans endorse it for its efficiency and reliability. It has become a staple in many large-scale operations where the safe transportation of pulverulent materials is a strict requirement. The machine aligns with international safety and quality standards, further cementing its status as a trusted component in industrial settings. Trustworthiness is a hallmark of this equipment, underscored by the rigorous testing each unit undergoes prior to deployment. It stands as a testament to the commitment of manufacturers to deliver machines that can be relied upon day in and day out, without compromise. Furthermore, service and support networks are robust, ensuring that any potential issues are addressed swiftly to minimize operational disruptions. Beyond just stitching, the Jumbo Bag Stitching Machine is often integrated into larger automated systems, demonstrating its versatility and adaptability. In multi-process manufacturing environments, these machines play a pivotal role in maintaining the flow of materials, which is critical for the continuous production line. This adaptation has transformed the traditional view of stitching as merely a closing method to a more holistic approach to material handling and processing. In conclusion, the Jumbo Bag Stitching Machine represents the pinnacle of innovation in industrial packaging solutions. Its blend of experience-based design, professional-grade engineering, and industry validation makes it an indispensable tool for businesses looking to enhance their operational sustainability and maintain competitive agility in today’s market. Having worked closely with these machines, I can confidently recommend them as a worthwhile investment for any organization looking to elevate its packaging and material handling prowess to new heights.

From an authoritative standpoint, the Jumbo Bag Stitching Machine is recognized across the industry as a transformative tool. Engineers and industry veterans endorse it for its efficiency and reliability. It has become a staple in many large-scale operations where the safe transportation of pulverulent materials is a strict requirement. The machine aligns with international safety and quality standards, further cementing its status as a trusted component in industrial settings. Trustworthiness is a hallmark of this equipment, underscored by the rigorous testing each unit undergoes prior to deployment. It stands as a testament to the commitment of manufacturers to deliver machines that can be relied upon day in and day out, without compromise. Furthermore, service and support networks are robust, ensuring that any potential issues are addressed swiftly to minimize operational disruptions. Beyond just stitching, the Jumbo Bag Stitching Machine is often integrated into larger automated systems, demonstrating its versatility and adaptability. In multi-process manufacturing environments, these machines play a pivotal role in maintaining the flow of materials, which is critical for the continuous production line. This adaptation has transformed the traditional view of stitching as merely a closing method to a more holistic approach to material handling and processing. In conclusion, the Jumbo Bag Stitching Machine represents the pinnacle of innovation in industrial packaging solutions. Its blend of experience-based design, professional-grade engineering, and industry validation makes it an indispensable tool for businesses looking to enhance their operational sustainability and maintain competitive agility in today’s market. Having worked closely with these machines, I can confidently recommend them as a worthwhile investment for any organization looking to elevate its packaging and material handling prowess to new heights.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025