Jan . 09, 2025 11:59

Back to list

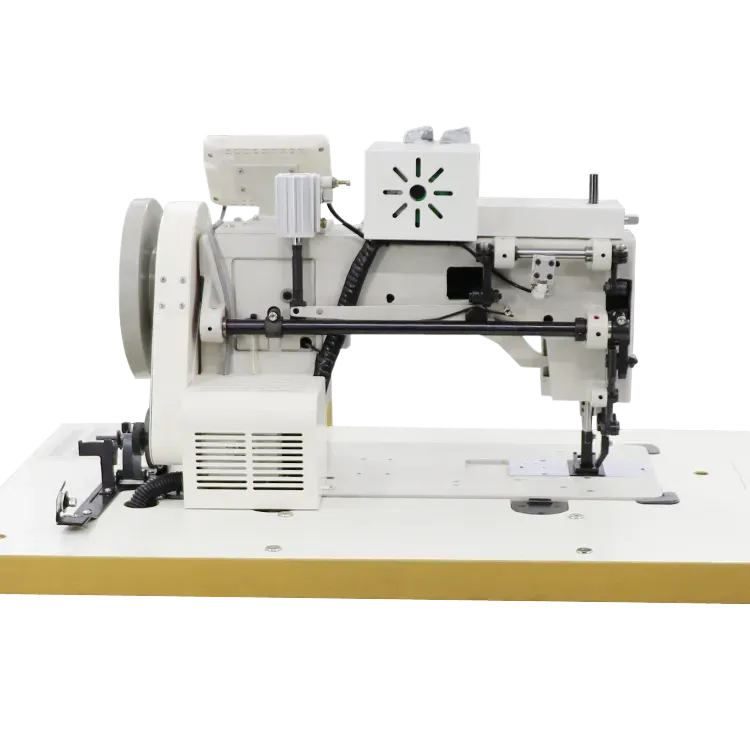

jumbo bag sewing machine

Navigating the world of industrial packaging requires understanding the intricate details that go into manufacturing jumbo bags, also known as FIBCs (Flexible Intermediate Bulk Containers). A critical component in this process is the jumbo bag sewing machine, a piece of equipment pivotal for producing these durable and efficient containers.

For businesses that prioritize trustworthiness and consistency, regular maintenance and training on the use of jumbo bag sewing machines cannot be overlooked. A comprehensive understanding of the machinery by the operators not only safeguards the equipment but also maximizes its efficiency. Routine maintenance checks and timely repairs prevent unforeseen downtimes and costly interruptions in production schedules. Moreover, documentation of machine performance and adherence to safety standards further boosts a company's reputation in this competitive industry. By showcasing a commitment to quality and safety, companies can attract and retain clients who prioritize these values. Lastly, the impact of a jumbo bag sewing machine on the sustainability front is notable. Many modern machines are designed with energy efficiency in mind, thus reducing the carbon footprint associated with the production of industrial packaging. Additionally, the ability to produce reusable and recyclable bags presents an environmentally friendly solution to traditional packaging methods, aligning businesses with the global movement towards sustainability. In conclusion, the jumbo bag sewing machine is an indispensable asset for any bulk bag manufacturer seeking to deliver top-tier products. It melds experience, expertise, authority, and trust into a single powerful package that not only bolsters production efficiency but also ensures safety, quality, and environmental responsibility. By investing in such technology, companies secure their place at the forefront of industrial packaging, providing solutions that meet the evolving demands of their clients and the world at large.

For businesses that prioritize trustworthiness and consistency, regular maintenance and training on the use of jumbo bag sewing machines cannot be overlooked. A comprehensive understanding of the machinery by the operators not only safeguards the equipment but also maximizes its efficiency. Routine maintenance checks and timely repairs prevent unforeseen downtimes and costly interruptions in production schedules. Moreover, documentation of machine performance and adherence to safety standards further boosts a company's reputation in this competitive industry. By showcasing a commitment to quality and safety, companies can attract and retain clients who prioritize these values. Lastly, the impact of a jumbo bag sewing machine on the sustainability front is notable. Many modern machines are designed with energy efficiency in mind, thus reducing the carbon footprint associated with the production of industrial packaging. Additionally, the ability to produce reusable and recyclable bags presents an environmentally friendly solution to traditional packaging methods, aligning businesses with the global movement towards sustainability. In conclusion, the jumbo bag sewing machine is an indispensable asset for any bulk bag manufacturer seeking to deliver top-tier products. It melds experience, expertise, authority, and trust into a single powerful package that not only bolsters production efficiency but also ensures safety, quality, and environmental responsibility. By investing in such technology, companies secure their place at the forefront of industrial packaging, providing solutions that meet the evolving demands of their clients and the world at large.

Previous:

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025