يناير . 21, 2025 02:03

Back to list

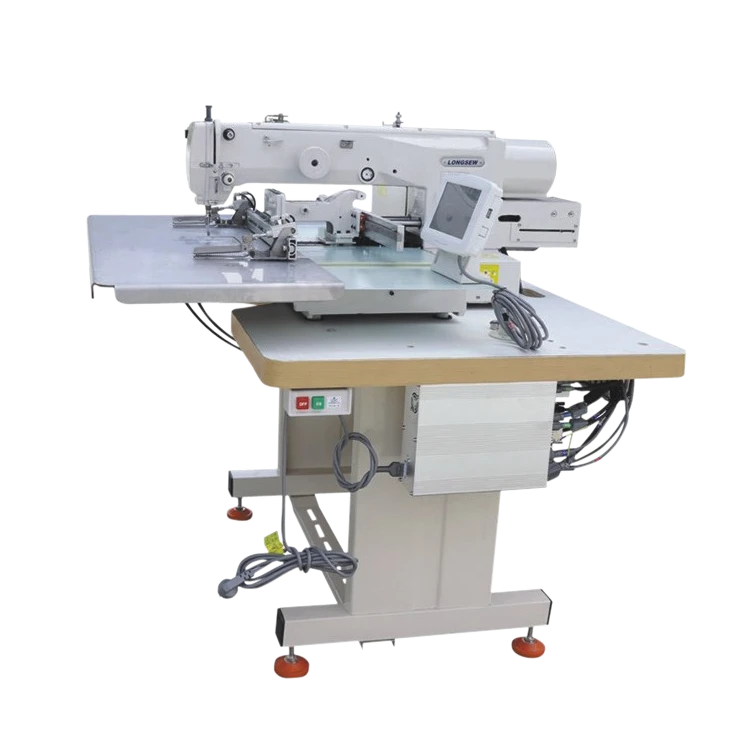

cnc leather sewing machine

In the realm of cutting-edge technology and precision craftsmanship, CNC leather sewing machines have emerged as a transformative force within the leatherworking industry. These sophisticated machines combine technological innovation with traditional sewing techniques to achieve unparalleled precision and efficiency. As an expert in the domain, I’m thrilled to delve into the distinct advantages and nuanced capabilities of CNC leather sewing machines, offering insights into their transformative impact on the industry.

Authoritativeness in CNC leather sewing also arises from the integration of advanced software solutions, which facilitate remote monitoring and real-time diagnostics. Manufacturers can optimize their production lines, swiftly adjust to design changes, and troubleshoot issues with minimal downtime, ensuring continuous operation and peak performance. This adaptability is crucial for meeting the ever-evolving demands of the fashion and automotive industries, where trends and customer preferences rapidly shift. Importantly, CNC leather sewing machines also bolster sustainability efforts within the industry. By maximizing material efficiency and reducing wastage, they contribute to eco-friendly manufacturing practices. Companies adopting this technology can appeal to environmentally-conscious consumers by promoting sustainable production processes and responsible resource management. This not only elevates brand reputation but also aligns with global movements towards greener technologies. Despite their numerous advantages, the mastery of CNC leather sewing machines requires a nuanced understanding of both the technology and the leather material. Professional training ensures operators can fully leverage the machine’s capabilities, maintaining machine health, and producing the highest quality products. Experts in the field emphasize the importance of continuous learning and adaptation as technology evolves. Trust in CNC leather sewing machines also stems from the reliability and consistency they offer to brands and consumers alike. By producing high-quality, durable products that meet stringent standards, these machines contribute significantly to brand reputation and customer satisfaction. Whether crafting luxury handbags, sturdy footwear, or custom automotive interiors, the results speak volumes for the precision and craftsmanship made possible by CNC technology. In summary, CNC leather sewing machines are not merely tools for production; they represent a paradigm shift within the leatherworking industry. By harmonizing advanced technology with artisanal craftsmanship, these machines unleash new potentials for precision, creativity, and environmental stewardship. As the industry continues to evolve, the adoption of CNC technology stands as a testament to embracing innovation while preserving the timeless art of leatherwork.

Authoritativeness in CNC leather sewing also arises from the integration of advanced software solutions, which facilitate remote monitoring and real-time diagnostics. Manufacturers can optimize their production lines, swiftly adjust to design changes, and troubleshoot issues with minimal downtime, ensuring continuous operation and peak performance. This adaptability is crucial for meeting the ever-evolving demands of the fashion and automotive industries, where trends and customer preferences rapidly shift. Importantly, CNC leather sewing machines also bolster sustainability efforts within the industry. By maximizing material efficiency and reducing wastage, they contribute to eco-friendly manufacturing practices. Companies adopting this technology can appeal to environmentally-conscious consumers by promoting sustainable production processes and responsible resource management. This not only elevates brand reputation but also aligns with global movements towards greener technologies. Despite their numerous advantages, the mastery of CNC leather sewing machines requires a nuanced understanding of both the technology and the leather material. Professional training ensures operators can fully leverage the machine’s capabilities, maintaining machine health, and producing the highest quality products. Experts in the field emphasize the importance of continuous learning and adaptation as technology evolves. Trust in CNC leather sewing machines also stems from the reliability and consistency they offer to brands and consumers alike. By producing high-quality, durable products that meet stringent standards, these machines contribute significantly to brand reputation and customer satisfaction. Whether crafting luxury handbags, sturdy footwear, or custom automotive interiors, the results speak volumes for the precision and craftsmanship made possible by CNC technology. In summary, CNC leather sewing machines are not merely tools for production; they represent a paradigm shift within the leatherworking industry. By harmonizing advanced technology with artisanal craftsmanship, these machines unleash new potentials for precision, creativity, and environmental stewardship. As the industry continues to evolve, the adoption of CNC technology stands as a testament to embracing innovation while preserving the timeless art of leatherwork.

Previous:

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025