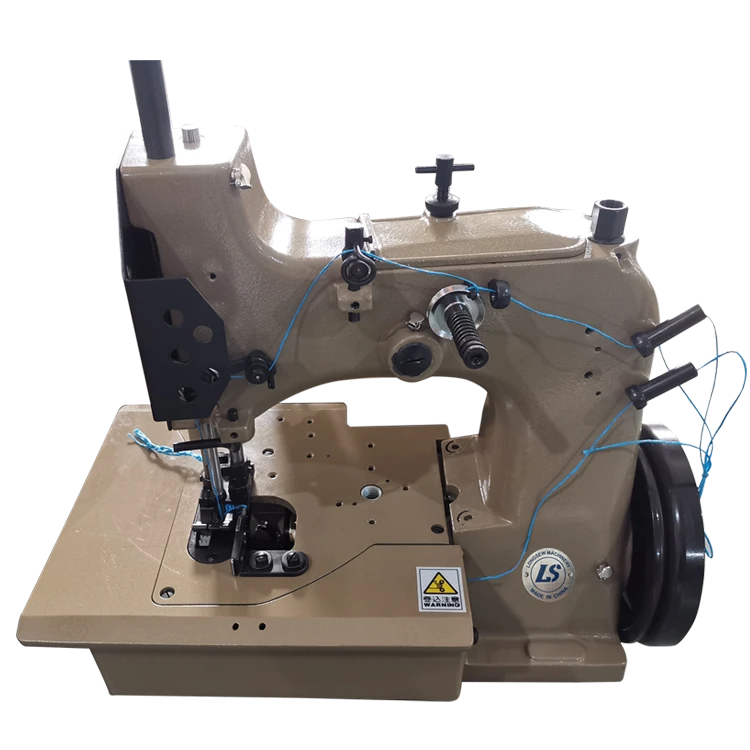

industrial lockstitch machine

Understanding the Industrial Lockstitch Machine A Cornerstone of Textile Manufacturing

The industrial lockstitch machine is a vital piece of equipment in the textile manufacturing sector. Renowned for its efficiency and versatility, this machine plays a crucial role in the production of a wide range of garments and textile products. The lockstitch mechanism produces a strong, secure stitch, making it ideal for sewing fabrics together in a variety of applications.

How the Lockstitch Machine Works

At the heart of the lockstitch machine is its unique stitching mechanism. It utilizes a needle and a bobbin thread to create a stitch that interlocks on both the top and bottom of the fabric. When the needle pierces the fabric, it pulls the upper thread down through, while the bobbin, located beneath the fabric, supplies the thread that loops back to form a secure stitch. This interlocking structure ensures durability and helps prevent unraveling, making it suitable for heavy-duty fabrics and seams that require extra strength.

Advantages of the Lockstitch Machine

One of the most significant advantages of the industrial lockstitch machine is its ability to produce high-quality stitches at rapid speeds. This capability dramatically increases productivity in bulk garment manufacturing. The uniformity of the lockstitch also enhances the aesthetic appeal of sewn products, making stitches nearly invisible on the fabric’s surface.

Additionally, the lockstitch machine is highly adaptable, supporting various stitching techniques such as straight stitching, zigzag stitching, and decorative stitching. Operators can easily switch between different classes of stitches based on the specific requirements of their projects. This feature increases the machine's functionality, making it suitable for multiple manufacturing settings, from clothing design to upholstery and beyond.

Applications in the Textile Industry

industrial lockstitch machine

Lockstitch machines are prevalent in numerous textile applications. In the apparel industry, they are employed to produce everything from simple t-shirts to complex, tailored suits. The machine’s versatility allows manufacturers to handle diverse fabrics, including cotton, polyester, and blends, ensuring they can meet different fashion demands while maintaining efficiency.

Moreover, the lockstitch machine is equally valuable in industries such as automotive textiles and upholstery, where sturdy seams are essential for product durability and safety. Additionally, it plays a crucial role in the production of household items like curtains, bed linens, and soft furnishings, proving its importance across various sectors.

Maintaining Industrial Lockstitch Machines

To maximize the performance and lifespan of an industrial lockstitch machine, regular maintenance is essential. Operators should routinely clean the machine, lubricate moving parts, and check for any wear or damage. Proper threading techniques and using the appropriate needle and thread sizes for specific materials can also prevent common issues like thread breaking or skipped stitches.

Training is another critical aspect of maintaining an efficient operation. Proper operation knowledge allows machine users to troubleshoot simple issues themselves, minimizing downtime and enhancing productivity. Investing in training and maintenance is crucial for any manufacturing facility looking to optimize its operations.

Conclusion

In summary, the industrial lockstitch machine is an indispensable tool in the textile industry, offering unmatched efficiency and versatility. Its innovative stitching mechanism provides strength and durability, catering to a wide array of applications, from fashion to home décor. As technology evolves, the lockstitch machine continues to adapt, ensuring its place at the forefront of textile manufacturing. For manufacturers, understanding and leveraging the capabilities of this machine is key to sustaining competitive advantages in a fast-paced industry.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025