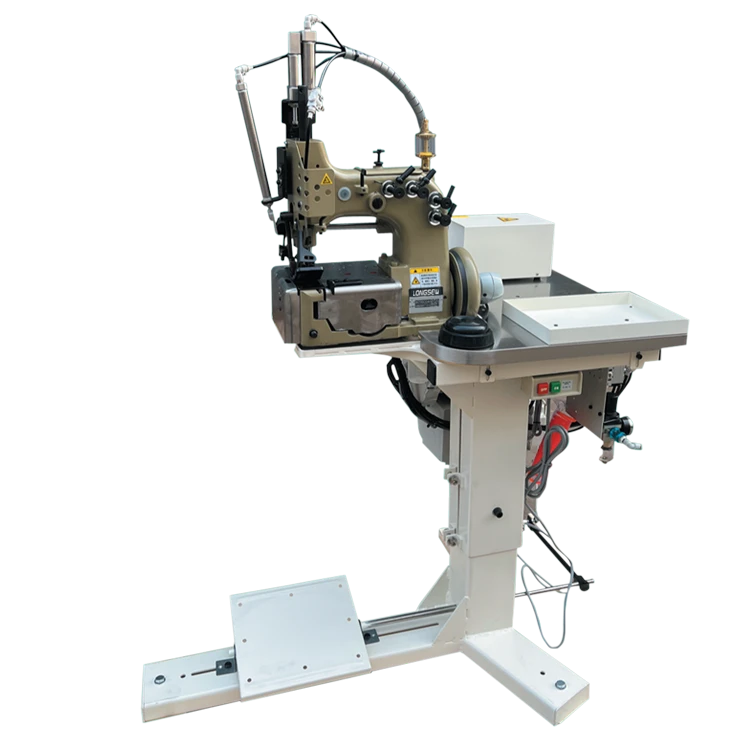

FIBC Sewing Machine

In the growing packaging industry, FIBC sewing machine plays a crucial role in manufacturing flexible intermediate bulk containers (FIBCs), commonly known as big bags. These bags are widely used across various industries, such as agriculture, chemicals, food, and construction, to store and transport bulk materials. The use of a FIBC sewing machine ensures that these bags are securely stitched and capable of carrying heavy loads while maintaining the highest standards of quality and durability.

The FIBC sewing machine is designed specifically to handle the unique needs of big bag production, where stitching strength, speed, and precision are paramount. Unlike traditional sewing machines, these specialized machines are equipped to handle thicker threads and heavier fabrics such as polypropylene (PP), which are commonly used in FIBC production. The machines are built to provide consistent, strong seams that can withstand the weight and stress of holding large quantities of bulk materials.

A key feature of the FIBC sewing machine is its ability to sew through multiple layers of fabric without compromising on performance. These machines are engineered to provide seamless stitching, which is essential for ensuring the bags do not burst or tear during use. Additionally, FIBC sewing machines come with automatic thread trimming, and adjustable stitch length and tension controls, making them highly efficient for large-scale production.

The demand for FIBC sewing machines has increased as more industries rely on bulk packaging solutions. With the growing importance of global trade, industries such as mining, food processing, and construction are in need of high-quality packaging systems to handle their large-volume shipments. The FIBC sewing machine is the ideal tool to meet these needs, ensuring strong and reliable bags that provide safe and efficient transport for a wide range of products.

Big Bag Sewing Machine: Optimizing Production Efficiency

In the world of industrial packaging, the big bag sewing machine is a vital piece of equipment that allows manufacturers to create large, sturdy bags used for transporting everything from grains to chemicals. The big bag sewing machine is specifically designed for sewing large-sized bags made from woven fabric, typically polypropylene, which needs to be durable, strong, and able to handle heavy loads.

One of the primary advantages of the big bag sewing machine is its ability to operate at high speeds while maintaining precision. With the growing demand for bulk storage and transport solutions, manufacturers need machinery that can produce large quantities of high-quality bags without sacrificing quality or time. The big bag sewing machine is built to provide optimal sewing performance with features such as automatic thread trimming, easy fabric handling, and a highly efficient stitch system.

Moreover, the big bag sewing machine comes with adjustable settings for different thread types and bag sizes, which makes it adaptable to the needs of different industries. Whether it's sewing a simple bag for grains or a specialized bag for hazardous chemicals, the machine can easily be adjusted to ensure the proper stitch strength and durability. The ability to work with various bag dimensions and materials makes the big bag sewing machine an indispensable tool for packaging companies that specialize in custom bulk bags.

A big bag sewing machine also provides benefits like improved worker safety, higher productivity, and reduced operational costs. With automated features, the machine minimizes human error and ensures consistent, high-quality results across all production runs. Additionally, these machines help companies maintain compliance with industry standards for bag quality and performance, ensuring that the final product is fit for the intended use.

Jumbo Bag Sewing Machine: Strength for the Toughest Applications

The jumbo bag sewing machine is an advanced type of industrial sewing machine designed specifically for sewing large-scale bulk bags, often referred to as jumbo bags or super sacks. These bags are used to transport very large quantities of materials like cement, fertilizers, grains, and other bulk commodities. Because of their size and the weight they need to carry, jumbo bag sewing machines must be capable of handling heavy-duty materials and thick, multi-layer fabrics.

A jumbo bag sewing machine is engineered to provide high-strength stitching that can endure the weight and pressure of large volumes of materials. The machine is built to sew through thick, reinforced fabrics like woven polypropylene and other materials commonly used in the production of jumbo bags. These fabrics need to be stitched with precision to ensure that they do not tear or break when filled with heavy contents. The jumbo bag sewing machine can produce durable seams that withstand the extreme conditions that these bags often encounter during storage, transportation, and handling.

In addition to its high sewing power, the jumbo bag sewing machine features advanced automation systems that reduce manual labor and improve production efficiency. With automated threading, fabric positioning, and stitch length control, the machine can work quickly and consistently, producing large volumes of jumbo bags in a short amount of time. This makes it particularly beneficial for industries that require a high throughput of bags, such as agriculture, mining, and construction.

The design of the jumbo bag sewing machine also takes into account ergonomic factors to ensure operator safety and comfort. Given the size of the bags and the heavy-duty stitching required, the machine is built to reduce operator fatigue and prevent injury. The machine’s user-friendly interface and intuitive controls allow operators to set up and operate the machine with minimal effort, further boosting efficiency in the production process.

FIBC Bag Sewing Machine FAQs

What is an FIBC sewing machine, and why is it important?

An FIBC sewing machine is a specialized industrial machine used for stitching flexible intermediate bulk containers (FIBCs), also known as big bags. These machines are important because they ensure that the bags are stitched with precision and durability, able to carry large volumes of materials without compromising on strength. The use of an FIBC sewing machine allows manufacturers to create high-quality, reliable bags suitable for various industries, including agriculture, chemicals, and construction.

How does a big bag sewing machine enhance production efficiency?

A big bag sewing machine enhances production efficiency by operating at high speeds while maintaining precision. These machines feature automatic thread trimming, adjustable stitch length, and tension controls, enabling manufacturers to produce large quantities of sturdy, high-quality bags quickly and with minimal error. The machine also reduces labor costs by automating much of the sewing process, improving overall productivity.

What types of materials can a jumbo bag sewing machine handle?

A jumbo bag sewing machine is designed to handle heavy-duty fabrics such as woven polypropylene, which is commonly used in the production of jumbo bags. These bags are often used to transport large quantities of materials like cement, fertilizer, and grains. The jumbo bag sewing machine can sew through thick, multi-layered fabrics, ensuring strong and durable seams that can withstand the pressure and weight of bulk materials.

What are the benefits of using a jumbo bag sewing machine?

The benefits of using a jumbo bag sewing machine include the ability to produce strong, durable bags capable of handling large volumes of materials. These machines increase production efficiency through automation, reducing manual labor and human error. They also improve safety for operators and provide consistent, high-quality results across large production runs. The jumbo bag sewing machine is particularly beneficial for industries that require high-volume bag production, such as mining, construction, and agriculture.

How do I choose the right sewing machine for big bags?

Choosing the right sewing machine for big bags depends on factors such as the type of material being used, the size of the bags, and the production speed required. For big bag sewing machines, look for features such as adjustable stitch length, automatic threading, and the ability to sew through thick fabrics like woven polypropylene. Additionally, consider the machine's efficiency, durability, and ease of operation to ensure it meets your production needs.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

fibc sewing machine

The Importance of FIBC Sewing Machines in the Packaging Industry

In the ever-evolving world of packaging, flexible intermediate bulk containers (FIBCs), also known as bulk bags, have become a staple for transporting bulk materials across various industries. These large, woven bags are known for their strength, durability, and versatility, making them ideal for storing and transporting products like chemicals, food grains, and construction materials. At the heart of this innovation is the FIBC sewing machine, a specialized piece of equipment designed to meet the unique requirements of FIBC manufacturing.

The Importance of FIBC Sewing Machines in the Packaging Industry

One of the critical features of an FIBC sewing machine is its ability to perform high-speed stitching. Given the demand for bulk bags in various industries, manufacturers are under pressure to produce large quantities quickly. High-speed machines can significantly increase productivity, allowing companies to meet market demands without compromising on quality. Moreover, these machines often come equipped with multiple needle systems, enabling them to sew intricate designs and patterns, which can include valves for filling and discharge, making the bags more functional.

fibc sewing machine

Moreover, advancements in technology have led to the development of automated FIBC sewing machines that integrate computer-controlled functions. These machines offer precision stitching, reduce material waste, and enhance overall efficiency in the production process. Automation also minimizes the risk of human error, leading to more consistent and reliable bag quality, which is essential for maintaining customer satisfaction and compliance with industry standards.

Environmental considerations have also played a role in the evolution of FIBC sewing machines. With the growing emphasis on sustainability, manufacturers are now focusing on using recyclable materials and adopting eco-friendly practices during the production process. Modern machines are designed to work with these sustainable materials, contributing to a greener packaging solution.

In conclusion, FIBC sewing machines are indispensable in the packaging industry. They not only facilitate the production of strong and reliable bulk bags but also adapt to the changing demands of the market. As industries continue to seek efficient and sustainable packaging solutions, the role of advanced FIBC sewing machines will only become more prominent, ensuring that businesses can efficiently transport goods while prioritizing safety and environmental responsibility.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025