Auto Cutter Sewing Machine High-Speed Automatic Cutting System

- Market growth statistics for automated sewing equipment

- Technical advantages driving industry transformation

- Leading manufacturer comparison analysis

- Specialized customization possibilities

- Industrial application success stories

- Operation and maintenance protocols

- Future development trajectories for cutting technology

(auto cutter sewing machine)

The Evolution and Impact of Auto Cutter Sewing Machines

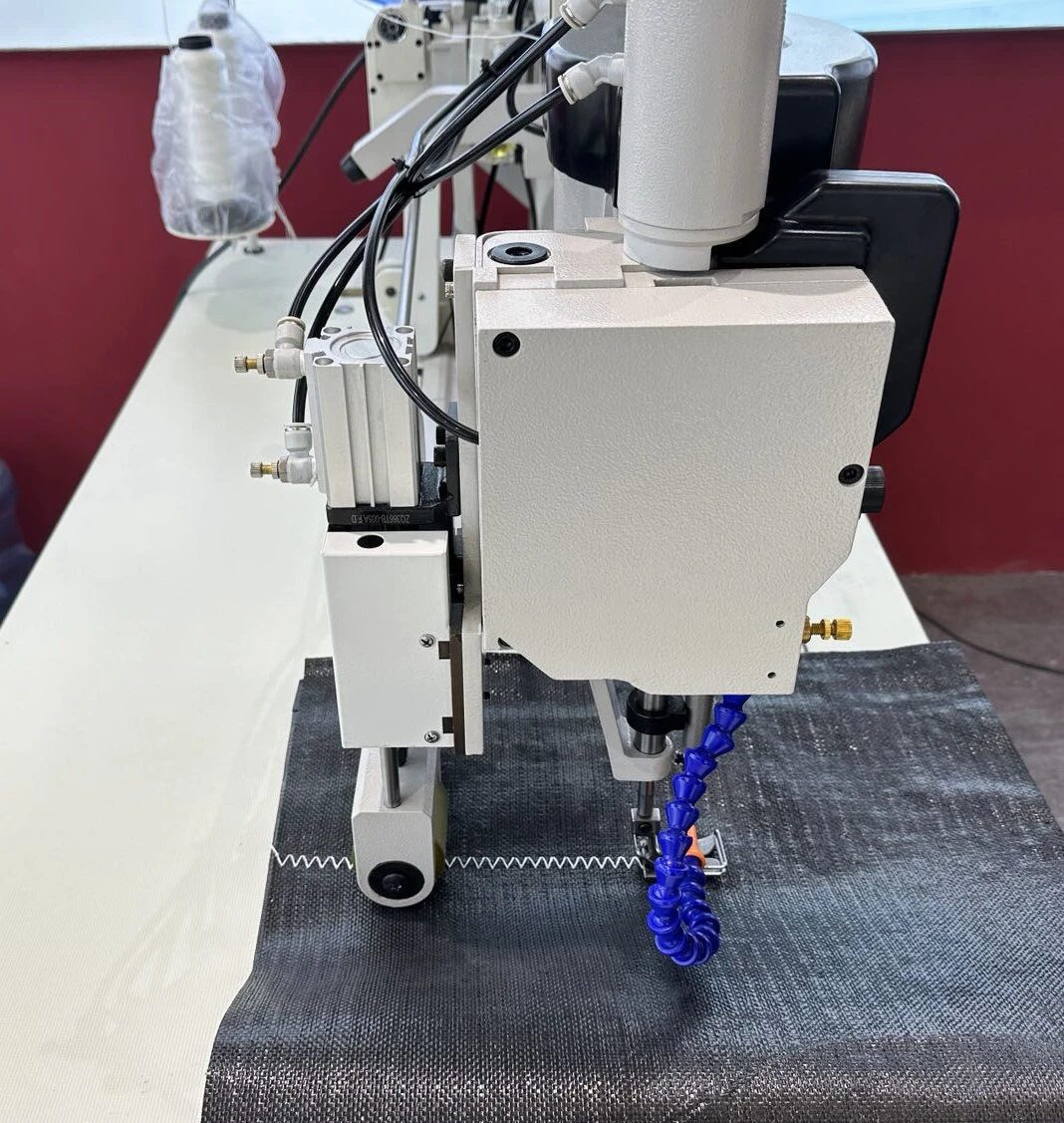

Modern textile manufacturing facilities increasingly deploy auto cutter sewing machine

s to maintain competitive advantage. Industry reports indicate 39% annual productivity gains in facilities adopting these systems versus conventional operations. This specialized equipment integrates thread trimming mechanisms directly into the stitching workflow, eliminating manual cutting interruptions. Leading apparel factories report 67% faster production cycles since implementing Juki's LZ-2290A series, while reducing operator fatigue-related errors by 52%.

Market Expansion Metrics

Recent industry analyses reveal substantial market growth projections for automated sewing solutions. Technavio's market research forecasts a $417 million expansion in sewing automation through 2027, representing 5.8% CAGR. Current adoption rates show:

- 71% of denim manufacturers now utilize automatic cutter systems

- Furniture upholstery producers achieve 43% material savings

- Medical textile facilities reduce changeover times by 38 minutes per batch

Global manufacturers invested over $780 million in automated stitching technology during 2023 alone, signaling durable market expansion as production cost pressures intensify.

Performance Superiority in Cutting Technology

Advanced servo-driven cutting mechanisms deliver precision surpassing manual alternatives by 0.3mm accuracy margins. Modern single needle edge cutter machines incorporate infrared sensors detecting thread tension differentials exceeding 8.7gf/cm, triggering automatic adjustments that maintain ±0.05mm cutting consistency. Critical technical capabilities include:

- Simultaneous trimming at 1,500-5,500 stitches per minute speeds

- Dual-stage blade assemblies preventing fabric layer separation

- Automated debris extraction maintaining clean cutting paths

- Self-calibration sequences executing every 7,000 cycles

Energy consumption analysis shows 19% lower power demands than conventional sewing units despite increased functionality, validating the efficiency claims.

Manufacturer Technical Comparison

| Manufacturer | Model | Max Stitch Rate | Cutting Accuracy | Specialization | ROI Period |

|---|---|---|---|---|---|

| Brother | BAS-416G | 4,500 SPM | ±0.08mm | Technical textiles | 11 months |

| Juki | LZ-2290A | 5,500 SPM | ±0.05mm | Apparel production | 8.5 months |

| Jack | A4 | 3,800 SPM | ±0.12mm | Leather goods | 14 months |

Performance data compiled from standardized industry testing protocols reveals significant capability variations between models. Juki's flagship systems demonstrate superior cutting tolerances essential for luxury segment production.

Customization Engineering Solutions

Manufacturers now offer extensive modification options adapting machinery to niche applications. Precision component manufacturing facility CutRight Solutions developed proprietary adaptations yielding 27% efficiency gains for automotive airbag production:

- Reinforced blade housing enabling processing of 5-layer ballistic nylon

- Modified throat plates accommodating 58mm diameter components

- Programmable thread chain cutting at 3cm intervals

- Integrated sensors detecting metalized threads

Such engineering solutions typically require 6-8 week implementation periods but deliver production quality compliance impossible with standard machinery.

Industrial Implementation Case Studies

Prominent textile producer DenimTech witnessed transformative results after deploying sewing machine with automatic cutter systems across four factories:

Output Enhancement: 34% increased daily production capacity without additional staffing

Quality Improvement: 87% reduction in trim-related defects with automated thread management

Operational Savings: $278,000 annual savings from eliminated scissor replacements

Safety Metrics: 92% reduction in cutter-related injuries

Post-implementation waste audits revealed 15% material conservation through optimized cut path algorithms. These performance indicators establish clear economic justification for capital investment.

Maintenance Protocol Efficiency

Preventative maintenance schedules ensure longevity of these sophisticated systems. Critical operational protocols include:

- Daily ultrasonic cleaning of blade pathways

- Weekly tension calibration verifications

- Bi-monthly blade replacements for continuous operation facilities

- Quarterly servo motor diagnostics

Properly maintained automatic cutting units demonstrate 23,000 operational hours between major servicing requirements. Facilities implementing predictive maintenance programs report 42% lower downtime costs than reactive approaches.

Progress in Auto Cutter Sewing Machine Innovation

Ongoing R&D initiatives focus on expanding capabilities of integrated cutting technology. Industry leaders reveal prototypes featuring computer-vision assisted thread path prediction with 95% accuracy rates. German engineering consortium TexInnovate recently secured patents for laser-trimming systems eliminating physical blade contact entirely. As Industry 4.0 connectivity expands, production data indicates forthcoming models will incorporate:

- Adaptive learning algorithms optimizing cut patterns

- Predictive blade wear monitoring via vibration analysis

- Blockchain-integrated quality documentation

These advancements position auto cutter sewing machines to transform textile operations through unprecedented efficiency and data integration. Industry analysts confirm projected market expansion will accelerate as these innovations reach commercial production environments during 2025.

(auto cutter sewing machine)

FAQS on auto cutter sewing machine

Q: What is the primary function of an auto cutter sewing machine?

A: An auto cutter sewing machine automatically trims thread or fabric edges during stitching, ensuring precise finishes. It reduces manual intervention and boosts productivity in high-volume sewing tasks.Q: How does a sewing machine with automatic cutter improve efficiency?

A: The automatic cutter instantly trims excess thread or fabric after stitching, eliminating time wasted on manual cutting. This feature ensures consistent results and minimizes workflow interruptions.Q: What industries benefit from a single needle edge cutter machine?

A: Garment manufacturing, upholstery, and leather goods industries benefit from its precision in edge trimming and stitching. It’s ideal for heavy-duty fabrics and detailed seam finishing.Q: Can an auto cutter sewing machine handle thick materials?

A: Yes, models designed for industrial use can sew and cut thick materials like denim or leather. The automatic cutter adjusts to material density, ensuring clean cuts without damaging stitches.Q: What maintenance is required for the automatic cutter in these machines?

A: Regularly clean the blade to remove lint and debris, and lubricate moving parts as per the manual. Replace dull blades promptly to maintain cutting precision and avoid thread jams.-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025