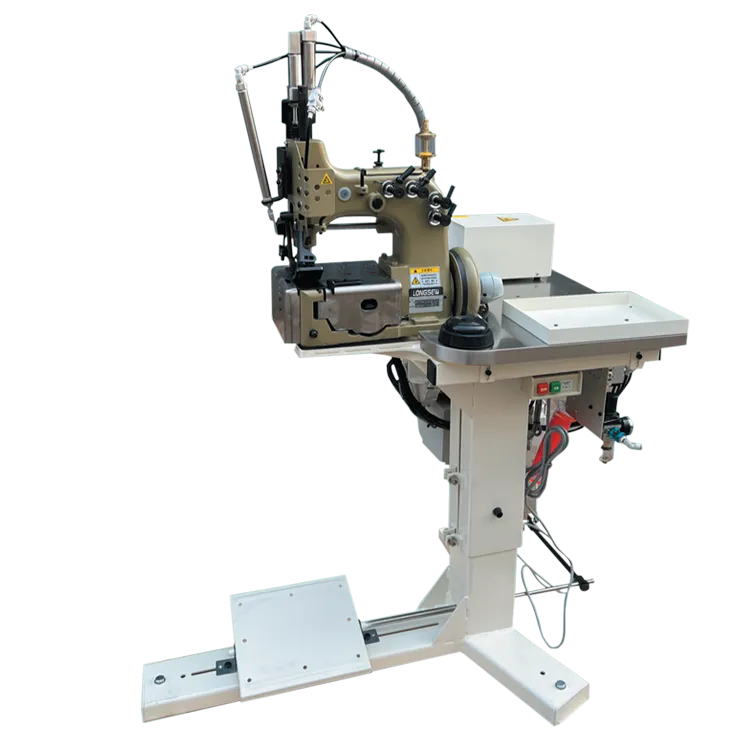

Application And Advantages Of Double Chain Sewing Machine

The double chain stitch serger, often an unsung hero in professional and home sewing, is a versatile tool that bridges the gap between efficiency and durability in stitching. A double chain stitch serger utilizes multiple threads to create a stitch that is not only secure but also flexible and aesthetically pleasing. This tool is a boon for both novice and expert sewers, delivering finished products with a professional touch. Understanding its mechanics, applications, and advantages is essential for those looking to elevate their sewing projects to the next level.

The fundamental process of a double chain stitch serger involves two needle threads and one or more looper threads working in unison. Unlike a typical sewing machine, which uses a single needle and bobbin thread, the double chain stitch serger forms interlocking loops, resulting in a more resilient and stretch-friendly seam. This type of stitch is especially useful in high-stress areas of garments that require a durable bond and frequent movement, such as sportswear, dance costumes, and fitted clothing. The robustness of this stitch makes it a preferred choice for producing professional-quality garments.

One of the primary advantages of the double chain stitch serger is its ability to handle a wide array of fabrics, from lightweight silks to heavy-duty denims. This versatility stems from the serger’s sophisticated stitching mechanism, which can be adjusted to accommodate the thickness and texture of different materials. When working with delicate fabrics, the serger can be set to apply minimal pressure, preventing puckering and ensuring smooth, even stitches. Conversely, for thicker fabrics, the double chain stitch serger can produce strong seams that withstand considerable wear and tear. This adaptability makes it an indispensable tool in a seamstress’s arsenal.

In addition to its mechanical prowess, the double chain stitch serger is lauded for its high-speed stitching capabilities. Standard sewing machines typically stitch at a rate of 600 to 800 stitches per minute, but a double chain stitch serger can operate at speeds upwards of 1,300 stitches per minute. This enhanced speed translates to greater productivity, allowing sewers to complete projects more swiftly without compromising on quality. For professional sewing operations and home sewers with substantial workloads, this increase in speed is a game-changer, enabling the efficient processing of multiple garments in a fraction of the time.

The double chain stitch serger also excels in edging and finishing, providing a polished, professional look to seams and garment edges. Traditional hemming techniques can often leave raw edges exposed, prone to fraying over time. In contrast, the serger’s looping mechanism securely wraps the thread around raw edges, preventing fraying and lending a clean, finished appearance. This feature is particularly advantageous when working with fabrics that are prone to unraveling, such as knits and woven textiles. The serger’s ability to effectively finish edges enhances the longevity and wearability of garments.

Despite its numerous advantages, mastering the double chain stitch serger requires practice and a nuanced understanding of its settings and capabilities. Beginners may initially find the threading process complex due to the multiple threads involved, but with time and guidance, threading becomes more intuitive. Many modern sergers come equipped with user-friendly features such as color-coded threading paths and automatic thread tension capabilities, simplifying the learning curve for new users. For those willing to invest the time and effort to master it, the double chain stitch serger is a profoundly rewarding tool that significantly enhances the quality and durability of sewn products.

In conclusion, the double chain stitch serger stands out as a powerful and versatile sewing tool that benefits both novice and seasoned sewers. Its durable, flexible stitching, adaptability to diverse fabric types, and high-speed operation make it a valuable asset in the creation of professional-quality garments. The serger’s impeccable edging capabilities ensure that seams and raw edges are neatly finished, extending the lifespan of finished products. While there is a learning curve associated with its use, the advantages far outweigh the initial challenges, making the double chain stitch serger an essential component of any advanced sewing setup. As more sewers discover its potential, the double chain stitch serger will undoubtedly continue to solidify its place as a cornerstone of efficient and high-quality sewing practices.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025