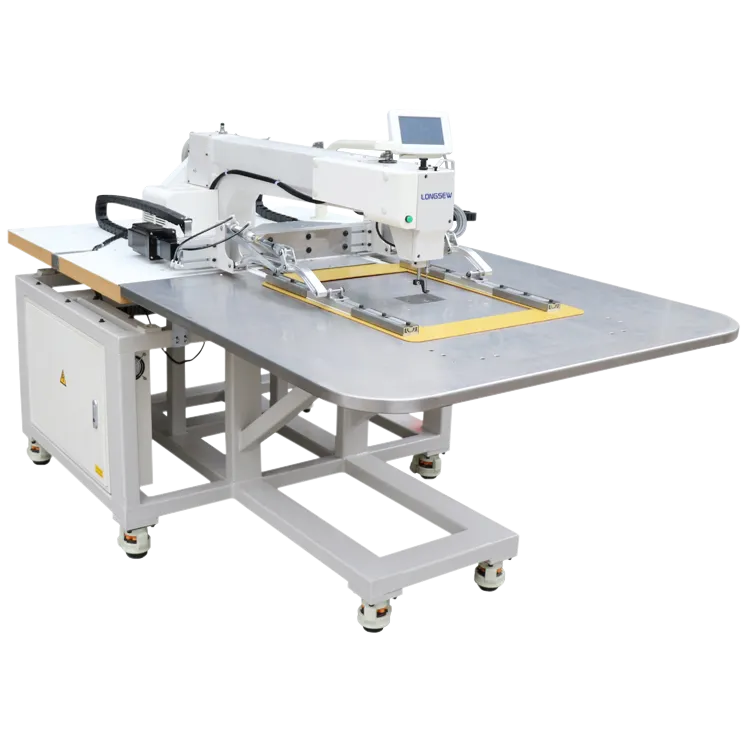

woven sack sewing machine

Woven Sack Sewing Machine A Technological Marvel in the Packaging Industry

In the world of packaging, woven sacks play a vital role in transporting various products ranging from grains, fertilizers, and chemicals to food items. The production of these durable sacks relies heavily on sophisticated machinery, most notably the woven sack sewing machine. This specialized equipment is designed to enhance productivity while ensuring high-quality stitching, essential for the integrity and durability of the sacks.

Understanding Woven Sacks

Woven sacks are made from polypropylene or polyethylene, which are woven into strong, resilient fabrics. Their design allows them to hold heavy loads, making them ideal for industries that require bulk packaging. These sacks come in various sizes and styles, depending on the specific needs of the products being stored or transported. However, without effective sewing solutions, the production of such sacks would be impractical and inefficient.

The Role of Sewing Machines

Woven sack sewing machines are specifically engineered to sew the edges of the woven fabrics, creating a secure closure that can withstand the rigors of transportation and handling. The sewing process requires precision and speed, and modern machines are equipped with advanced technology to fulfill these needs. They offer features such as automatic threading, adjustable stitch length, and multiple needle options, which contribute to enhancing productivity and reducing material waste.

Types of Woven Sack Sewing Machines

There are several types of sewing machines specifically designed for woven sacks. These include

1. Lock Stitch Sewing Machines Traditional lock stitch machines are the most widely used for sewn bags. They create a tight stitch that prevents the contents of the bag from spilling out.

2. Chain Stitch Sewing Machines These machines operate using a chain stitch technique, which is particularly useful for high-speed production. They allow for quicker sewing and are less expensive in terms of thread consumption.

woven sack sewing machine

3. Overlock Sewing Machines Often utilized for finishing edges, overlock machines can sew and cut fabric simultaneously. This is particularly advantageous in the woven sack manufacturing process as it creates a clean edge, reducing the chances of fraying.

4. High-Speed Sewing Machines Designed for mass production, high-speed machines can significantly increase output while maintaining stitching quality, which is crucial for large-scale manufacturing plants.

5. Automatic Sewing Machines These machines offer automation features that streamline the sewing process, including automatic feeding of the material, which minimizes human intervention and increases efficiency.

Innovations in Woven Sack Sewing Machines

Recent advancements in technology have precipitated significant innovations in woven sack sewing machines. Modern machines now incorporate programmable logic controllers (PLCs) which allow operators to adjust settings digitally. This technology not only simplifies the setup process but also enhances accuracy and consistency in production.

Additionally, the integration of servo motors has revolutionized the sewing industry, providing quieter operation and greater energy efficiency. These motors can respond rapidly to the machine's needs, reducing downtime and improving overall productivity.

The Importance of Quality Control

In the production of woven sacks, quality control is essential. A robust sewing process ensures that the bags are durable and fit for purpose. Manufacturers often implement rigorous testing protocols to assess the strength of the seams and the overall quality of the sacks. Investing in high-quality sewing machines is critical to minimizing defects and ensuring that the end product meets industry standards.

Conclusion

The woven sack sewing machine is an indispensable tool in the packaging industry, facilitating the production of high-quality, durable sacks that are essential for transporting goods. As technology continues to advance, these machines are becoming more efficient, versatile, and user-friendly. The future of woven sack manufacturing looks promising, driven by innovation and the constant pursuit of quality. The efficiency offered by modern sewing machines not only boosts productivity but also contributes significantly to the sustainability and reliability of the packaging industry as a whole.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025