Single Needle FIBC Bag Design for Enhanced Durability and Efficiency in Packaging

The Importance of FIBC Bags in Modern Packaging Solutions

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, have revolutionized the storage and transportation of bulk materials across industries. Among the various methods of manufacturing FIBC bags, single needle sewing has emerged as a reliable and efficient technique that enhances the strength and durability of these bags. This article delves into the significance of FIBC bags and the specific advantages of employing single needle stitching in their production.

The Importance of FIBC Bags in Modern Packaging Solutions

One of the foremost advantages of FIBC bags is their ability to optimize space and reduce shipping costs. These bags can be collapsed when empty, which allows for efficient storage and transportation. This characteristic is especially beneficial in a global economy where logistics play a crucial role in maintaining competitiveness. By maximizing the amount of product that can be shipped at one time, companies can significantly reduce their carbon footprint and improve overall efficiency.

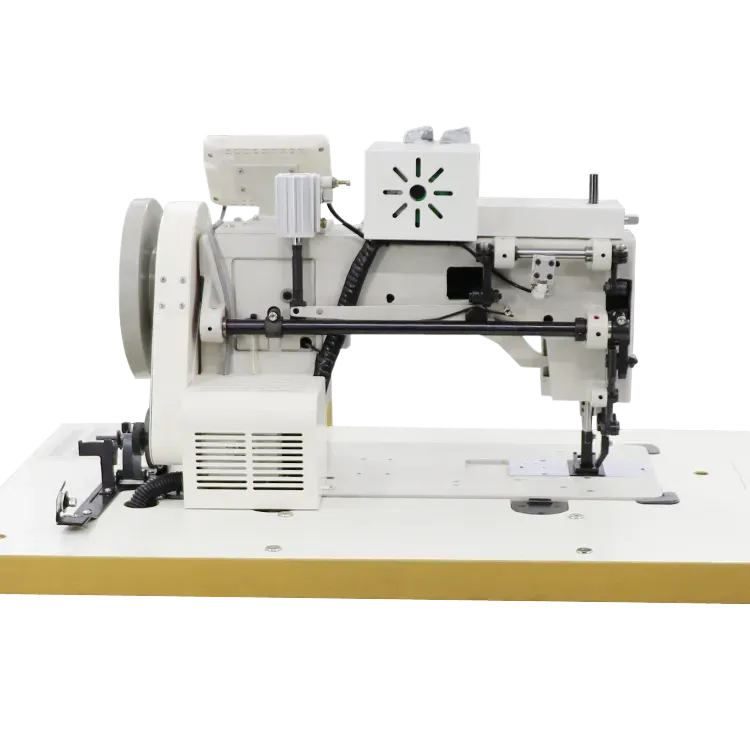

fibc bag single needle

When it comes to the construction of FIBC bags, the choice of stitching method can significantly impact their performance. Single needle sewing is one of the most prevalent techniques used in the industry. This method involves stitching the bag's seams with a single needle, which creates a strong and durable seam that can withstand the rigors of heavy-duty use. The precision of single needle sewing ensures that the seams are uniform and tightly secured, minimizing the risk of spills or ruptures during handling and transport.

Single needle stitching also allows for the incorporation of additional features such as liners and coatings that enhance the bag's functionality. For instance, when producing bags for food-grade materials, manufacturers can use a single needle to attach a liner that ensures product safety and compliance with industry regulations. This adaptability is vital in meeting the stringent standards that different sectors require.

Moreover, single needle sewn FIBC bags can be produced quickly and cost-effectively, which benefits suppliers and manufacturers alike. The streamlined process reduces the time from production to market, allowing companies to respond swiftly to changing demands. As businesses look for ways to enhance their supply chain operations, the efficiency brought about by single needle sewing cannot be overstated.

In conclusion, the role of FIBC bags in modern packaging solutions is indispensable, particularly when coupled with advanced stitching techniques like single needle sewing. These bags provide a robust, space-efficient, and cost-effective means of transporting bulk materials, making them essential in various industries. As the market continues to evolve, the importance of high-quality manufacturing processes, including the choice of stitching methods, will only grow, ensuring that FIBC bags remain at the forefront of packaging innovations. With their unique advantages, FIBC bags are set to play a crucial role in meeting the challenges of contemporary supply chains.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025