The debate between investing in a standard sewing machine versus a heavy-duty one is often settled by understanding their respective costs over a more extended period. But how do the two compare when we look into the economics of maintaining each over time?

Standard sewing machines are typically designed for everyday home projects. They are built to handle lighter fabrics and less frequent use. Consequently, their initial purchase price is usually more affordable than their heavy-duty counterparts. However, standard machines can wear out faster, especially if pushed beyond their capacity, leading to potential frequent repairs or replacements.

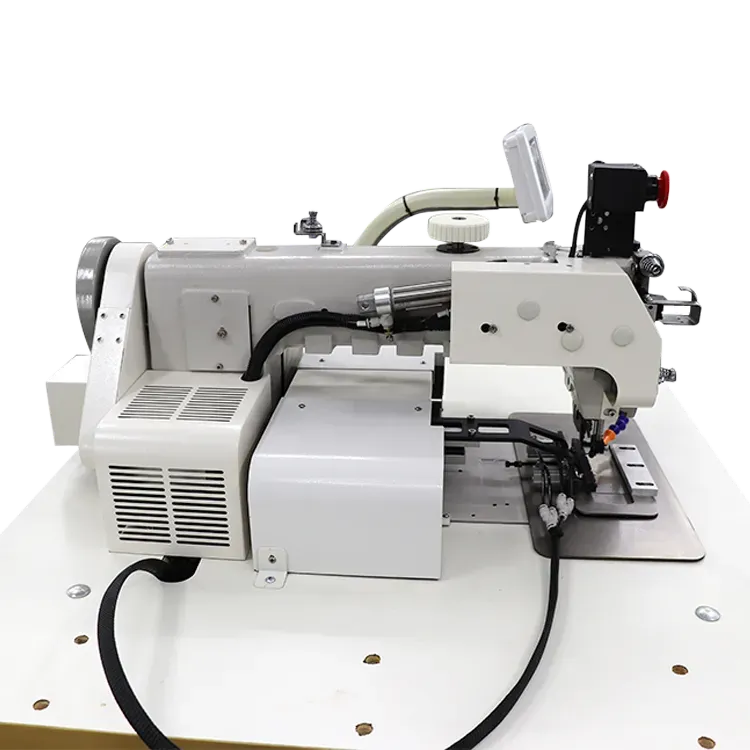

In contrast, heavy-duty sewing machines are designed for durability and to handle various projects that standard machines can’t, such as working with multiple layers of thick fabric. Their robust build means fewer breakdowns and longer intervals between necessary maintenance or repairs. Though their initial cost is higher, the reduced frequency of repairs and their longer lifespan can make them more economical in the long run.

Case Studies Comparing Costs Over Time

Consider a fictional example: Sarah, a budding fashion designer, started with a standard machine. Over five years, she spent an average of $100 annually on maintenance, and by the sixth year, she had to replace the machine, costing her another $400—her total expenditure over six years: $1000.

Contrast this with Jane, a professional upholsterer who initially invested in a heavy-duty machine costing $700. Over six years, she spent an average of $50 annually on maintenance—her total over six years: $1000.

While both spent $1000 over six years, Jane had the advantage of a machine that could handle more complex projects, ensuring she didn’t turn down work or compromise on quality.

Testimonials from Users of Heavy-Duty Sewing Machines

Aria, a costume designer, shares, “I switched to a heavy-duty machine two years ago, and it’s transformed my work. I can now handle a wider range of fabrics, and the machine doesn’t falter even with constant use.”

Mark, a craftsman specializing in leather goods, mentions, “The investment in a heavy-duty machine has paid off. I can work faster, and the stitch quality, even on thick leather, is impeccable.”