Feb . 14, 2025 08:58

Back to list

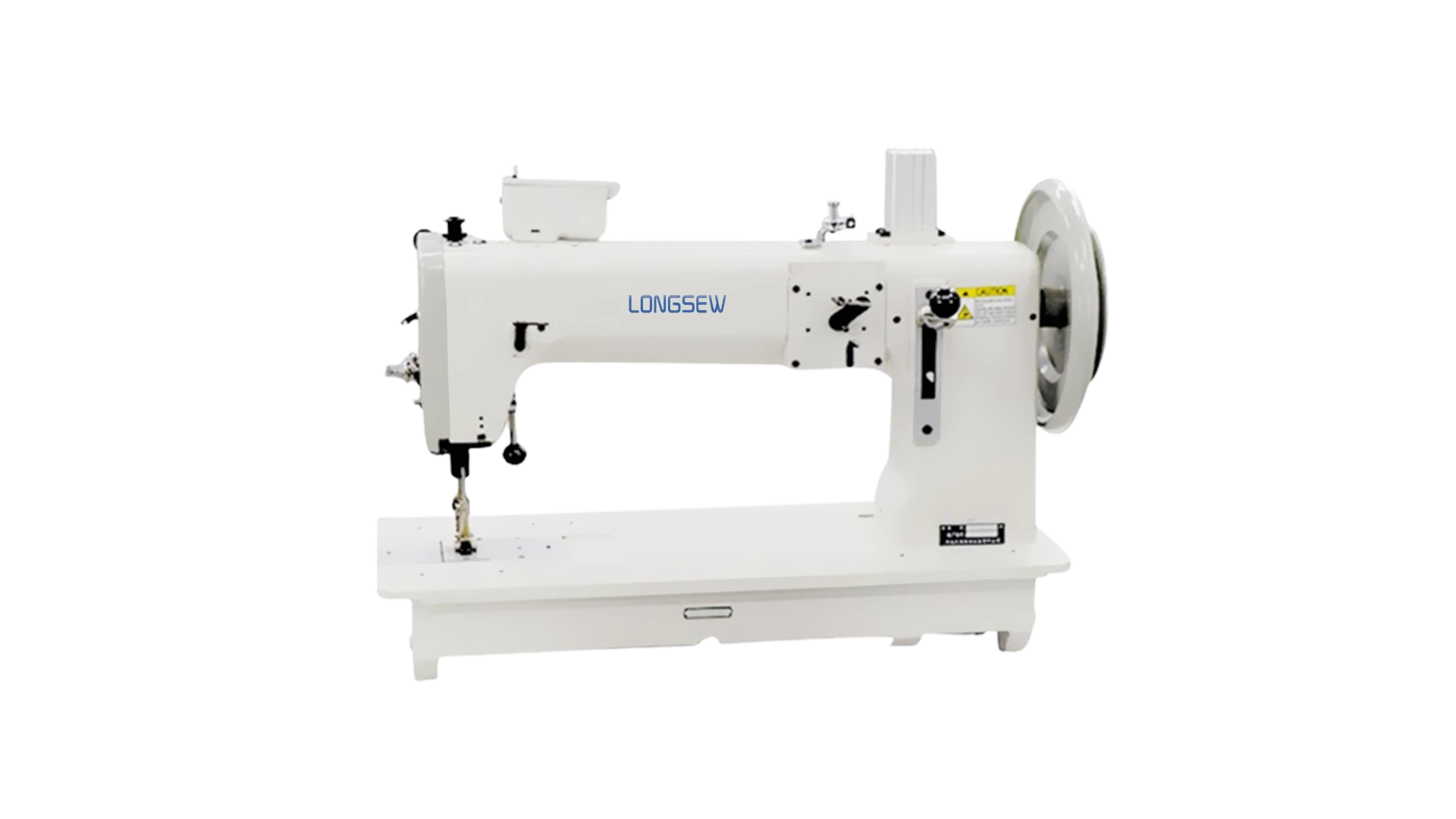

typical leather sewing machine

Whether you are a seasoned craftsman or a budding hobbyist, understanding the ins and outs of a typical leather sewing machine is crucial to mastering the art of leatherwork. Tailored for those who demand precision and durability, these machines stand apart in their design and functionality, setting a gold standard in craftsmanship.

Authoritativeness in the leather sewing domain can be best illustrated by acknowledging historical craftsmanship traditions. Renowned leather goods, ranging from tailor-made saddles to bespoke shoes, owe their quality to the unwavering precision that only a leather sewing machine can provide. Brands synonymous with luxury have long utilized these machines to foster products that bear the hallmark of meticulous craftsmanship, with each stitch marking a legacy of excellence. This underscores the machine's authority in the industry as an indispensable tool for artisans dedicated to creating timeless pieces. Trustworthiness is paramount when selecting a leather sewing machine, as this investment directly impacts the quality and durability of the crafted goods. A typical leather machine, renowned for its reliability, garners trust through decades of proven performance. Users often cite machines like the Juki DNU-1541 and the Singer 4411 as stalwarts in the field, commending their resilience and consistent output. The choice of a reputable machine brand, known for rigorous quality control and comprehensive support, further instills confidence among users, reinforcing trust in their purchase decision. In conclusion, the typical leather sewing machine is not merely an adjunct to the leatherworking process but rather its heart. It embodies a convergence of experience, expertise, authority, and trust that few tools rival. For those who aspire to create leather goods that are not only functional but celebrated as works of art, investing in and mastering these machines is an essential step on the road to craftsmanship excellence. As you navigate the world of leather sewing, let the legacy and innovation of these machines guide each stitch, transforming raw material into timeless elegance.

Authoritativeness in the leather sewing domain can be best illustrated by acknowledging historical craftsmanship traditions. Renowned leather goods, ranging from tailor-made saddles to bespoke shoes, owe their quality to the unwavering precision that only a leather sewing machine can provide. Brands synonymous with luxury have long utilized these machines to foster products that bear the hallmark of meticulous craftsmanship, with each stitch marking a legacy of excellence. This underscores the machine's authority in the industry as an indispensable tool for artisans dedicated to creating timeless pieces. Trustworthiness is paramount when selecting a leather sewing machine, as this investment directly impacts the quality and durability of the crafted goods. A typical leather machine, renowned for its reliability, garners trust through decades of proven performance. Users often cite machines like the Juki DNU-1541 and the Singer 4411 as stalwarts in the field, commending their resilience and consistent output. The choice of a reputable machine brand, known for rigorous quality control and comprehensive support, further instills confidence among users, reinforcing trust in their purchase decision. In conclusion, the typical leather sewing machine is not merely an adjunct to the leatherworking process but rather its heart. It embodies a convergence of experience, expertise, authority, and trust that few tools rival. For those who aspire to create leather goods that are not only functional but celebrated as works of art, investing in and mastering these machines is an essential step on the road to craftsmanship excellence. As you navigate the world of leather sewing, let the legacy and innovation of these machines guide each stitch, transforming raw material into timeless elegance.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025