Feb . 14, 2025 08:38

Back to list

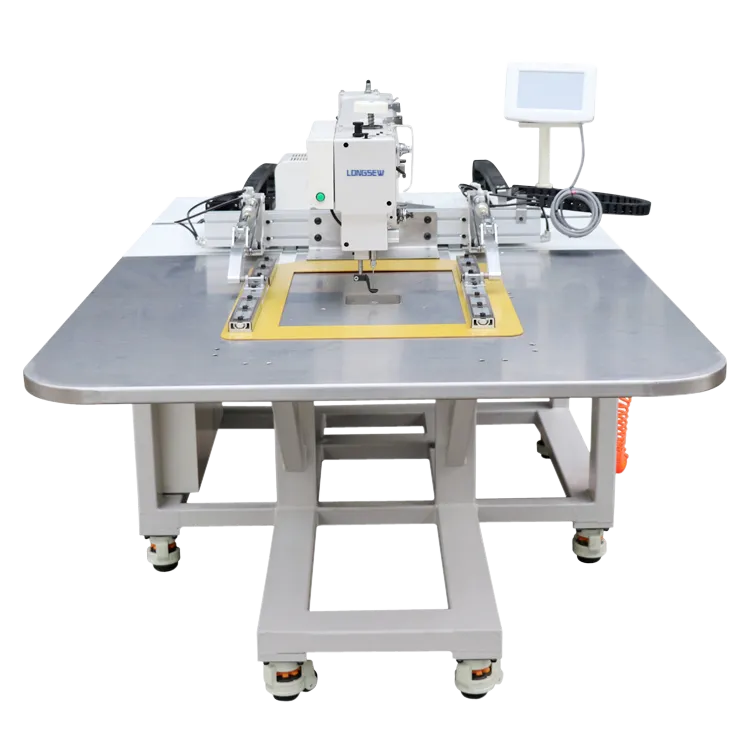

types of leather sewing machines

Navigating the intricate world of leather sewing machines can feel overwhelming. The array of options available on the market today is both expansive and technically nuanced. This guide dives into the core types of leather sewing machines, focusing on delivering an expert-level understanding to ensure your choices align with both your craft's demands and your business's goals.

Walking foot machines, also known as compound feed machines, are tailored for medium to heavy-leather types, where consistent feeding is crucial. Their synchronization between feed dogs and presser foot prevents slip between layers, ensuring precise, even stitches across thicker leather stacks or quilted designs. These machines are indispensable for products requiring significant strength and durability, such as saddles and heavy-duty upholstery. Artisans often favor models that provide a robust reverse function and a powerful servo motor for superior performance across various leather densities. Hand Crank Leather Sewing Machines Although traditional, hand crank machines have made a niche comeback among bespoke leather artisans. Ideal for light-duty tasks or for hobbyists working on smaller, unique pieces like figurines or artistic patches, these machines offer complete manual control over stitching speed and accuracy. Often lauded for their portability and low maintenance, they allow for delicate, precision work without the need for electrical input. Quality hand crank machines, such as those manufactured by Singer, offer dependable performance with simplicity. Computerized Leather Sewing Machines The digital age has ushered in computerized sewing machines that take artisanal leather work to new heights. Equipped with programmable stitch patterns, automatic thread trimming, and touch-screen interfaces, these machines blend technology with traditional craftsmanship. Perfect for complex design execution, they allow for repeatability and precision difficult to achieve manually. Consider models from Brother or Elna that offer extensive stitch libraries and USB connectivity, enabling bespoke craftsmanship with consistency. Conclusion Investing in the right type of leather sewing machine hinges on understanding both the specific requirements of your craft and the capabilities of each machine type. Mastery in leatherwork demands machines that match the skill and creativity of the artisan, propelling their craft to new directions while maintaining the cherished quality of handmade excellence. Each machine type offers unique features and benefits, capable of elevating your craftsmanship by enhancing precision, efficiency, and creativity. Whether restoring vintage items or designing innovative new pieces, selecting the appropriate machine can significantly impact your artistic and commercial success.

Walking foot machines, also known as compound feed machines, are tailored for medium to heavy-leather types, where consistent feeding is crucial. Their synchronization between feed dogs and presser foot prevents slip between layers, ensuring precise, even stitches across thicker leather stacks or quilted designs. These machines are indispensable for products requiring significant strength and durability, such as saddles and heavy-duty upholstery. Artisans often favor models that provide a robust reverse function and a powerful servo motor for superior performance across various leather densities. Hand Crank Leather Sewing Machines Although traditional, hand crank machines have made a niche comeback among bespoke leather artisans. Ideal for light-duty tasks or for hobbyists working on smaller, unique pieces like figurines or artistic patches, these machines offer complete manual control over stitching speed and accuracy. Often lauded for their portability and low maintenance, they allow for delicate, precision work without the need for electrical input. Quality hand crank machines, such as those manufactured by Singer, offer dependable performance with simplicity. Computerized Leather Sewing Machines The digital age has ushered in computerized sewing machines that take artisanal leather work to new heights. Equipped with programmable stitch patterns, automatic thread trimming, and touch-screen interfaces, these machines blend technology with traditional craftsmanship. Perfect for complex design execution, they allow for repeatability and precision difficult to achieve manually. Consider models from Brother or Elna that offer extensive stitch libraries and USB connectivity, enabling bespoke craftsmanship with consistency. Conclusion Investing in the right type of leather sewing machine hinges on understanding both the specific requirements of your craft and the capabilities of each machine type. Mastery in leatherwork demands machines that match the skill and creativity of the artisan, propelling their craft to new directions while maintaining the cherished quality of handmade excellence. Each machine type offers unique features and benefits, capable of elevating your craftsmanship by enhancing precision, efficiency, and creativity. Whether restoring vintage items or designing innovative new pieces, selecting the appropriate machine can significantly impact your artistic and commercial success.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025