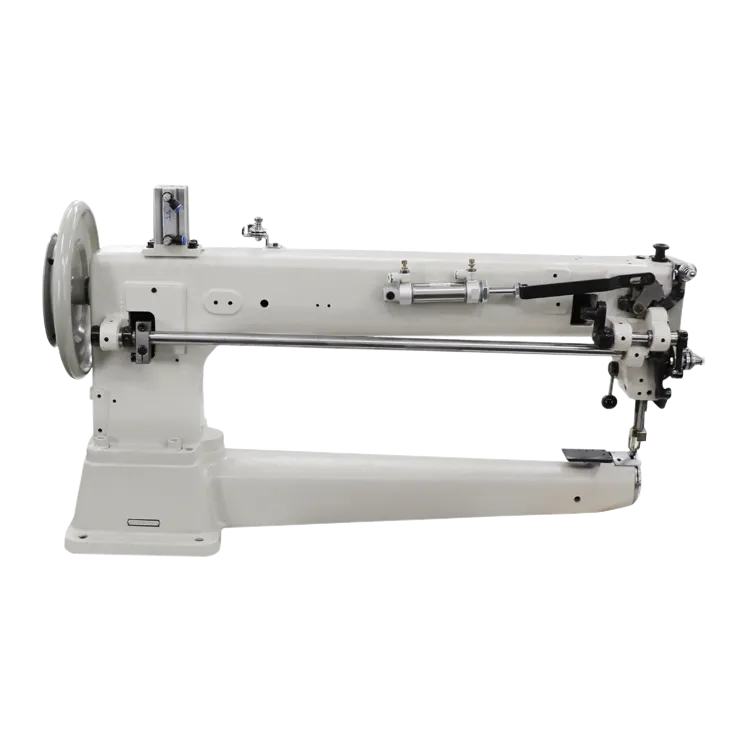

straight and zigzag industrial sewing machine

Straight and Zigzag Industrial Sewing Machines A Comprehensive Overview

In the world of industrial sewing, machines play a crucial role in determining the efficiency and quality of production. Among the various types of sewing machines available, straight and zigzag industrial sewing machines are two of the most commonly used. Each type has distinct features and functions, making them suitable for different sewing tasks and applications. In this article, we will explore the characteristics, advantages, and uses of straight and zigzag industrial sewing machines.

Straight Stitch Industrial Sewing Machines

Straight stitch sewing machines are primarily designed to produce a straight line of stitches, which is the most fundamental type of stitch in garment construction. These machines are characterized by their robustness and durability, making them ideal for high-volume sewing tasks. They typically feature a high-speed operation, allowing them to sew quickly while maintaining consistent stitch quality.

One of the key advantages of straight stitch machines is their ability to handle thicker materials, such as denim and canvas, without compromising on stitch quality. They are commonly used in various industries, including garment manufacturing, upholstery, and textile production. The simplicity of their design also means that they require less maintenance compared to more complex machines.

Straight stitch machines are often equipped with features like automatic needle positioners, adjustable presser foot pressure, and programmable settings, enhancing their usability in various production environments. Moreover, the ease of use makes them a popular choice for both seasoned professionals and beginners in the sewing industry.

Zigzag Industrial Sewing Machines

On the other hand, zigzag industrial sewing machines offer more versatility compared to their straight-stitch counterparts. As the name suggests, these machines can produce zigzag stitches in addition to straight stitches. This ability allows for various applications, such as decorative stitching, hemming, and overlocking. Zigzag stitches are particularly useful when working with stretch fabrics, as they allow the fabric to maintain its elasticity.

straight and zigzag industrial sewing machine

Zigzag machines come with multiple stitch width and length settings, allowing users to customize their stitching for specific requirements. This flexibility is invaluable in settings where diverse fabric types and designs are common. Furthermore, zigzag machines often feature advanced capabilities such as embroidery functions and automatic thread tension adjustments, making them suitable for more complex sewing tasks.

The ability to perform a range of stitch types makes zigzag machines an essential tool in industries like fashion design, home décor, and textiles. They are also increasingly used in quilting and advanced garment construction for embellishments and finishing techniques that elevate the final product.

Choosing Between Straight and Zigzag Machines

When selecting between straight and zigzag industrial sewing machines, it is essential to consider the specific needs of the sewing operation. For high-volume production of basic garments, straight stitch machines are often the most efficient choice. They excel in speed and reliability, making them perfect for mass production environments.

Conversely, when versatility and the ability to work with different stitch types are required, zigzag sewing machines take precedence. They offer the flexibility needed for various applications, making them a valuable asset in settings where creativity and diverse fabric handling are priorities.

Conclusion

In conclusion, both straight and zigzag industrial sewing machines play vital roles in the textile and garment industries. Understanding their functionalities and strengths allows manufacturers and sewing enthusiasts to choose the right machine for their specific needs. Whether it's the robustness of a straight stitch machine or the versatility of a zigzag sewing machine, investing in the right technology can significantly enhance productivity and the overall quality of the final product. As industrial sewing continues to evolve, these machines will remain at the forefront, enabling innovative designs and efficient production processes.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025