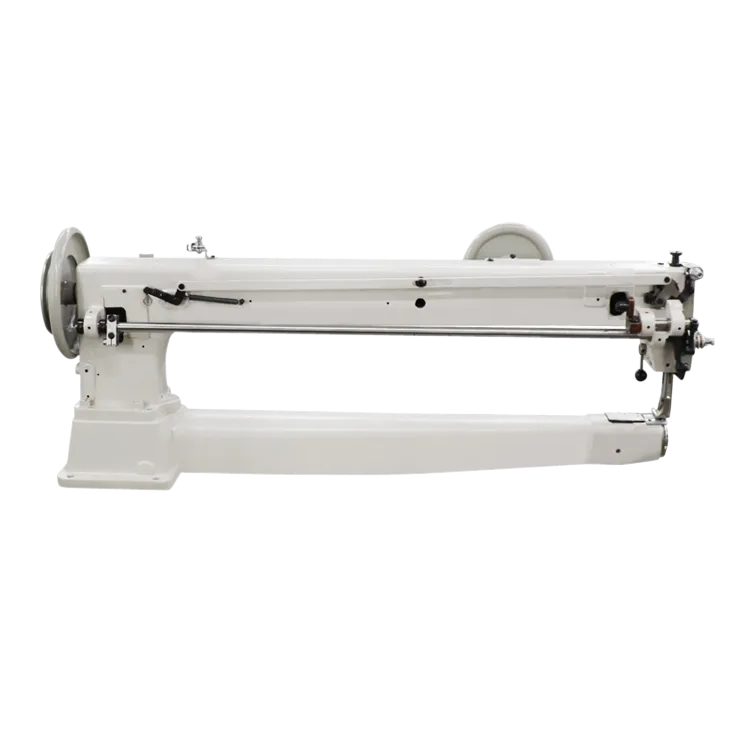

fully automatic sewing machine

Exploring the Future of Textile Production Fully Automatic Sewing Machines

In the rapidly advancing world of technology, the textile industry is experiencing a revolution with the introduction of fully automatic sewing machines. These sophisticated machines are reshaping the way garments are manufactured, contributing to efficiency, precision, and sustainability. This article aims to explore the functionality, benefits, and future potential of fully automatic sewing machines.

The Mechanisms Behind Fully Automatic Sewing Machines

At the core of fully automatic sewing machines is an advanced integration of robotics, artificial intelligence, and machine learning. These machines are equipped with sensors and cameras that allow them to detect fabric types, patterns, and imperfections. This capability enables automatic adjustments to stitching techniques and tension, ensuring consistent quality in every garment produced. Additionally, with touch-screen interfaces and programmable options, operators can input design specifications and watch as the machine executes the tasks with minimal human intervention.

The fully automatic sewing machines also incorporate multiple functions such as cutting, folding, and sewing. This integration significantly reduces the number of steps in the garment-making process and minimizes the need for manual labor. By streamlining operations, manufacturers can increase productivity and reduce lead times, which is particularly important in a fast-fashion world where speed is vital.

The Benefits of Fully Automatic Sewing Machines

The advantages of adopting fully automatic sewing machines are manifold. Firstly, they enhance precision and consistency in sewing. Traditional sewing methods are prone to human error, leading to inconsistencies that can result in product defects. In contrast, automated machines maintain uniformity across thousands of garments, ensuring that each item meets quality standards.

Secondly, these machines significantly increase productivity. With the capability to operate continuously and with high speeds, fully automatic sewing machines can produce garments at a fraction of the time it takes with manual sewing. This increased efficiency allows companies to meet market demands swiftly and effectively.

fully automatic sewing machine

Moreover, fully automatic sewing machines contribute to sustainability in the fashion industry. They minimize fabric waste by utilizing precise cutting and stitching methods. Additionally, the reduced labor costs associated with automation can allow manufacturers to invest in more sustainable practices like using eco-friendly materials or improving working conditions for remaining employees.

The Future Landscape of the Textile Industry

Looking ahead, the potential for fully automatic sewing machines is enormous. As technology continues to evolve, we can expect even greater integration of artificial intelligence, enabling machines to learn from previous sewing experiences and progressively refine their techniques. This capability could lead to personalized garment production, where clothing can be tailored to individual preferences with even less human input.

Furthermore, industries outside of fashion are beginning to take notice of the applications of fully automatic sewing technology. Potential markets include automotive textiles, interior design, and even medical fabrics. The versatility of these machines suggests they could transform various sectors by providing custom solutions at scale.

However, the shift toward automation also raises questions about the future of employment in the textile industry. While the use of fully automatic sewing machines could reduce the demand for manual labor, it could also create new opportunities for highly skilled workers who can operate and maintain this advanced technology. Balancing automation with human labor will be crucial in ensuring a just transition for workers in the industry.

Conclusion

Fully automatic sewing machines are not just a trend; they represent a significant leap forward in the textile and fashion manufacturing sectors. By combining technology with creativity, this innovation is poised to redefine garment production, enhancing quality, efficiency, and sustainability. As we embrace these machines, it is essential to consider their impact on the workforce and strive for a balance that benefits all stakeholders in the industry. The future of textile production is indeed exciting, and fully automatic sewing machines are at the forefront of this transformation.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025