Jan . 19, 2025 05:18

Back to list

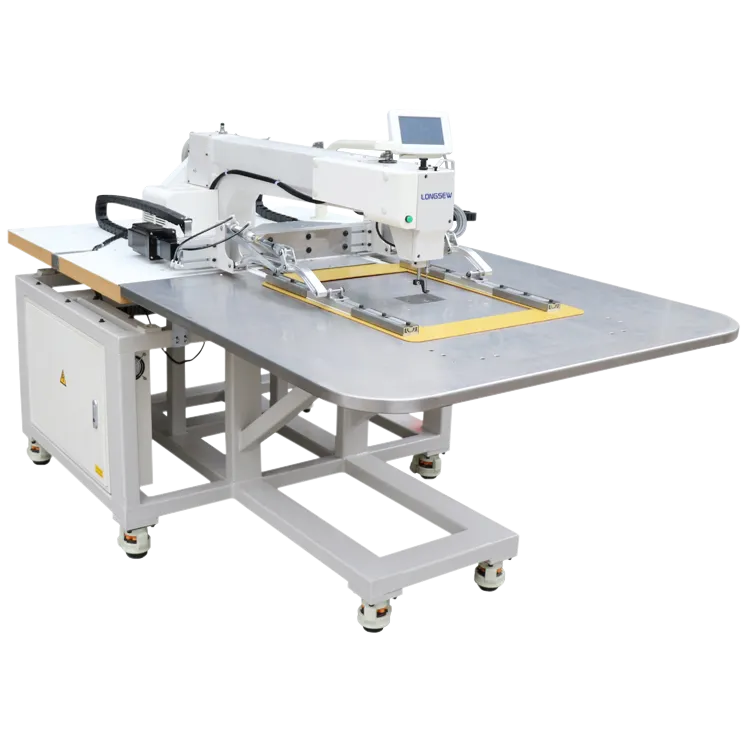

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367/GSC367TD /GSC367TDZ/ GSC367-L.

Threading a single needle lockstitch machine can be a daunting task for beginners, yet mastering this skill is a foundational step in sewing expertise. The lockstitch mechanism, commonly found in home and industrial machines, uses two threads to create a strong, reliable seam. By understanding the specific threading paths and tension settings, users can achieve professional results in their sewing projects.

Adjusting thread tension is a nuanced task requiring careful attention. For most fabrics, the default factory settings suffice; however, situations arise that demand manual adjustment. Tighten or loosen the tension using the threaded dial, conducting stitch tests on fabric scraps to find the ideal balance. Proper tension ensures that the threads lock exactly in the fabric’s center, which is the hallmark of a perfect stitch. Exploring other features such as stitch length and presser foot pressure can further enhance stitch quality. Regularly cleaning the machine and oiling its parts ensures smooth operation and longevity. Additionally, using specific presser feet, such as a zipper foot or walking foot, can facilitate specialized sewing techniques, broadening the machine’s application scope. Safety cannot be overlooked; always switch off the machine when threading to prevent accidents. Utilize proper lighting to ensure clear visibility of threading points and needle eye, minimizing errors that lead to inefficient threading or needle breakage. Embracing the nuances of threading a single needle lockstitch machine empowers sewers to undertake diverse projects, from delicate fabrics to rugged materials, with confidence. By honing these skills, individuals not only enjoy the creative process but also produce durable and aesthetically pleasing results, making the mastery of lockstitch machine threading an indispensable part of sewing expertise. This knowledge underpins a solid understanding of sewing machinery, elevating user capabilities, and contributing to a more fulfilling sewing experience. For further professional insights, regularly consulting sewing forums and engaging with the global sewing community enriches one's knowledge base, offering troubleshooting tips and advanced threading techniques. Such continuous learning is key to honing craftsmanship and ensuring the production of top-quality garments and textile products.

Adjusting thread tension is a nuanced task requiring careful attention. For most fabrics, the default factory settings suffice; however, situations arise that demand manual adjustment. Tighten or loosen the tension using the threaded dial, conducting stitch tests on fabric scraps to find the ideal balance. Proper tension ensures that the threads lock exactly in the fabric’s center, which is the hallmark of a perfect stitch. Exploring other features such as stitch length and presser foot pressure can further enhance stitch quality. Regularly cleaning the machine and oiling its parts ensures smooth operation and longevity. Additionally, using specific presser feet, such as a zipper foot or walking foot, can facilitate specialized sewing techniques, broadening the machine’s application scope. Safety cannot be overlooked; always switch off the machine when threading to prevent accidents. Utilize proper lighting to ensure clear visibility of threading points and needle eye, minimizing errors that lead to inefficient threading or needle breakage. Embracing the nuances of threading a single needle lockstitch machine empowers sewers to undertake diverse projects, from delicate fabrics to rugged materials, with confidence. By honing these skills, individuals not only enjoy the creative process but also produce durable and aesthetically pleasing results, making the mastery of lockstitch machine threading an indispensable part of sewing expertise. This knowledge underpins a solid understanding of sewing machinery, elevating user capabilities, and contributing to a more fulfilling sewing experience. For further professional insights, regularly consulting sewing forums and engaging with the global sewing community enriches one's knowledge base, offering troubleshooting tips and advanced threading techniques. Such continuous learning is key to honing craftsmanship and ensuring the production of top-quality garments and textile products.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025