Feb . 13, 2025 17:52

Back to list

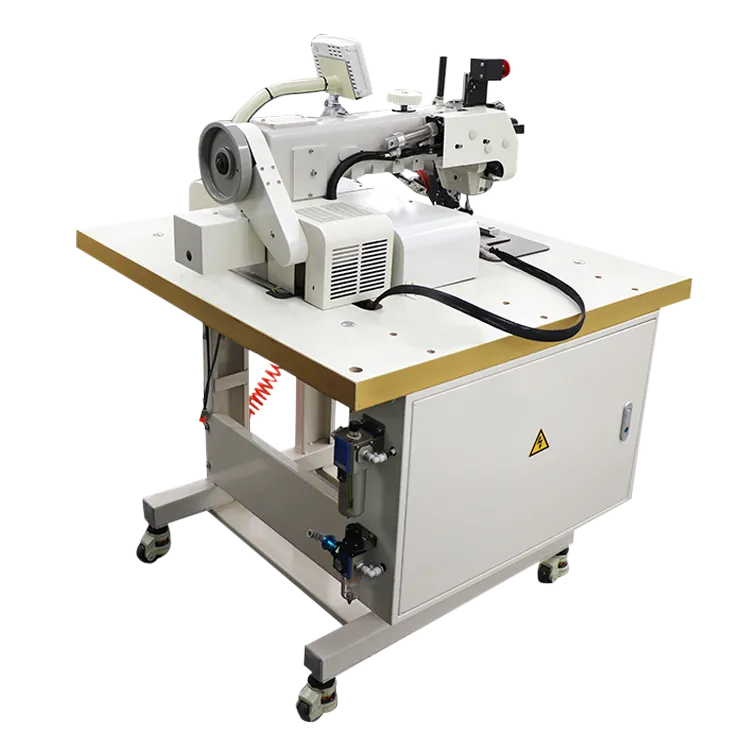

Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N

Successfully stitching leather with a regular sewing machine is not only possible but a fascinating process that can open doors to numerous creative projects. While leatherwork might seem daunting at first, achieving professional results doesn't necessarily require specialized equipment. With the right techniques, tools, and patience, anyone can embark on leather uncharted territories using their everyday sewing machine.

Preparation and Marking Techniques Preparation is at the heart of any successful project. Marking leather requires more thought since pin holes are permanent. Using tailor’s chalk or specialized pencils that can wipe away easily helps prevent lasting marks. Applying a light adhesive or double-sided tape can hold pieces in place without requiring pins. Clip edges instead of using pins when potential slipping or movement is a concern, particularly helpful in layered projects such as bags or patches. Careful marking ensures every stitch aligns perfectly. Understanding Edges and Finishing Edging tools can add a professional touch to your creations. Tools for beveling can soften sharp edges while burnishing involves rubbing edges with tools to achieve a polished appearance. This step is as crucial as the stitching, enhancing durability and aesthetics. Applying edge coat or beeswax can add a protective layer to your finished project. Thus, incorporating finishing into your process increases both the quality and longevity of your leather pieces. Safety and Care for the Machine Maintaining your sewing machine becomes even more critical during and after working with leather. Establish a routine of frequent cleaning, oiling, and replacing needles when using them on leather. This practice extends the life of your equipment and ensures it's always functioning at peak performance. Listening to the machine's motor is a good practice; any unusual sounds may indicate added stress or misalignment due to material thickness, warranting immediate adjustments. Creating a Community Lastly, exploring forums, communities, or workshops dedicated to crafting with leather can provide a wealth of information and support. Engaging with like-minded enthusiasts enables the exchange of tips and troubleshooting advice that might not be covered in manuals or guides. It builds a resourceful support network that enhances learning and engages people of all levels in a shared passion. Leveraging a regular sewing machine to create stunning leather pieces is an exercise in patience, precision, and practice. As this fascinating craft grows, so does the ability to push creative boundaries with confidence. With each completed project, you’ll gain invaluable skills that transform every piece of leather into something extraordinary, ultimately creating a unique signature in your handmade masterpieces.

Preparation and Marking Techniques Preparation is at the heart of any successful project. Marking leather requires more thought since pin holes are permanent. Using tailor’s chalk or specialized pencils that can wipe away easily helps prevent lasting marks. Applying a light adhesive or double-sided tape can hold pieces in place without requiring pins. Clip edges instead of using pins when potential slipping or movement is a concern, particularly helpful in layered projects such as bags or patches. Careful marking ensures every stitch aligns perfectly. Understanding Edges and Finishing Edging tools can add a professional touch to your creations. Tools for beveling can soften sharp edges while burnishing involves rubbing edges with tools to achieve a polished appearance. This step is as crucial as the stitching, enhancing durability and aesthetics. Applying edge coat or beeswax can add a protective layer to your finished project. Thus, incorporating finishing into your process increases both the quality and longevity of your leather pieces. Safety and Care for the Machine Maintaining your sewing machine becomes even more critical during and after working with leather. Establish a routine of frequent cleaning, oiling, and replacing needles when using them on leather. This practice extends the life of your equipment and ensures it's always functioning at peak performance. Listening to the machine's motor is a good practice; any unusual sounds may indicate added stress or misalignment due to material thickness, warranting immediate adjustments. Creating a Community Lastly, exploring forums, communities, or workshops dedicated to crafting with leather can provide a wealth of information and support. Engaging with like-minded enthusiasts enables the exchange of tips and troubleshooting advice that might not be covered in manuals or guides. It builds a resourceful support network that enhances learning and engages people of all levels in a shared passion. Leveraging a regular sewing machine to create stunning leather pieces is an exercise in patience, precision, and practice. As this fascinating craft grows, so does the ability to push creative boundaries with confidence. With each completed project, you’ll gain invaluable skills that transform every piece of leather into something extraordinary, ultimately creating a unique signature in your handmade masterpieces.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025