Feb . 13, 2025 16:59

Back to list

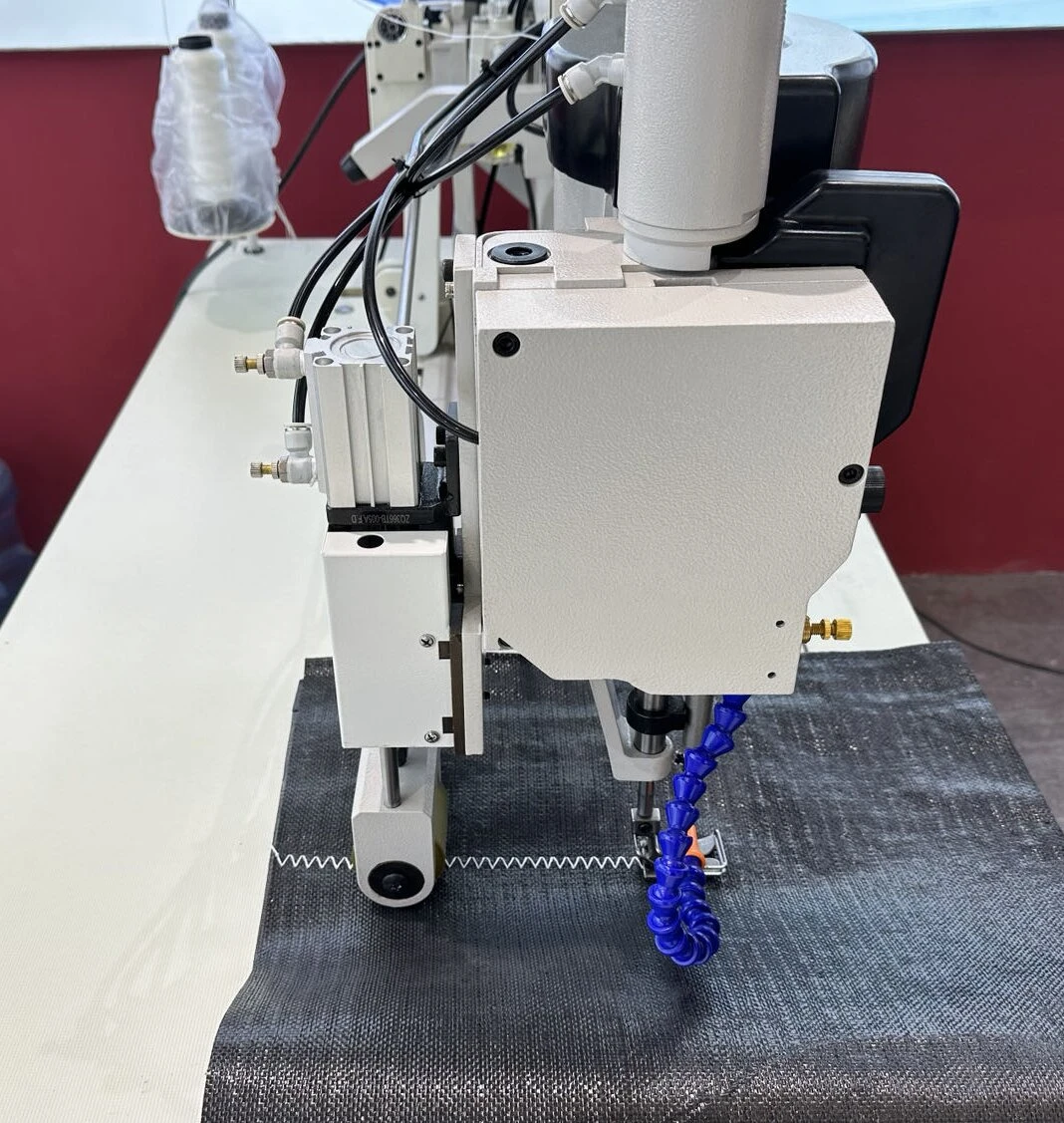

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

Sewing leather on a domestic machine might initially seem daunting due to the material's robustness and thickness, contrasting the lightweight fabrics these machines are designed for. However, with the right approach, tools, and techniques, it's entirely feasible to produce high-quality leather projects from the comfort of your home. This guide aims to provide an authoritative and trustworthy roadmap for enthusiasts and beginners alike, tapping into the expertise accumulated from years of practical experience.

Project Ideas and Practical Experience Handbags, belts, and wallets are excellent beginner projects for those sewing leather on a domestic machine. These projects not only require patterns that are relatively straightforward but also provide a canvas for testing different stitches and techniques. Experience has shown that starting with smaller projects allows for acclimatization to leather's unique properties, gradually building confidence before tackling larger, more complex designs. These undertakings not only enhance personal expertise but also ensure each crafted piece holds a practicality and durability expected from leather goods. Projects grounded in utility ensure that the time invested in skillfully sewing leather results in everyday items of tangible value. Overcoming Common Challenges Despite careful preparation, challenges such as stitch inconsistency or difficulty in maintaining alignment may arise. Such concerns typically stem from inadequate machine calibration or thread tension. Should these issues present themselves, re-evaluate the needle and thread selection, and adjust the tension settings accordingly. Genuine leather varies in thickness and texture, meaning minor adjustments are often necessary. Building an understanding of these adjustments over time fosters a level of expertise that transforms challenges into manageable tasks. Final Thoughts on Trustworthiness Undertaking leather sewing on a domestic machine exemplifies a melding of creativity and craftsmanship. It demands a commitment to maintaining tools and continuously honing skills. Sharing such experiences and successful methods contributes not only to one's growth but enriches a community of like-minded crafters. When deciding to trust information regarding leather sewing, rely on sources with proven expertise and feedback from experienced users who attest to the reliability of approaches and tools discussed. A foundation built on trust and shared knowledge ensures that each sewing project embarked upon isn't just about the end product but the journey of craftsmanship itself.

Project Ideas and Practical Experience Handbags, belts, and wallets are excellent beginner projects for those sewing leather on a domestic machine. These projects not only require patterns that are relatively straightforward but also provide a canvas for testing different stitches and techniques. Experience has shown that starting with smaller projects allows for acclimatization to leather's unique properties, gradually building confidence before tackling larger, more complex designs. These undertakings not only enhance personal expertise but also ensure each crafted piece holds a practicality and durability expected from leather goods. Projects grounded in utility ensure that the time invested in skillfully sewing leather results in everyday items of tangible value. Overcoming Common Challenges Despite careful preparation, challenges such as stitch inconsistency or difficulty in maintaining alignment may arise. Such concerns typically stem from inadequate machine calibration or thread tension. Should these issues present themselves, re-evaluate the needle and thread selection, and adjust the tension settings accordingly. Genuine leather varies in thickness and texture, meaning minor adjustments are often necessary. Building an understanding of these adjustments over time fosters a level of expertise that transforms challenges into manageable tasks. Final Thoughts on Trustworthiness Undertaking leather sewing on a domestic machine exemplifies a melding of creativity and craftsmanship. It demands a commitment to maintaining tools and continuously honing skills. Sharing such experiences and successful methods contributes not only to one's growth but enriches a community of like-minded crafters. When deciding to trust information regarding leather sewing, rely on sources with proven expertise and feedback from experienced users who attest to the reliability of approaches and tools discussed. A foundation built on trust and shared knowledge ensures that each sewing project embarked upon isn't just about the end product but the journey of craftsmanship itself.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025