Feb . 13, 2025 16:26

Back to list

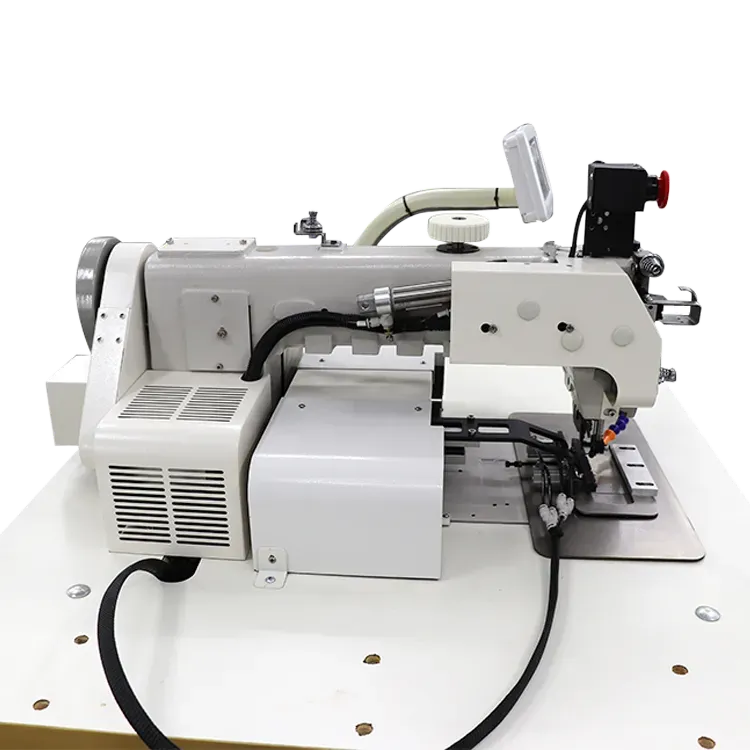

leather cylinder arm sewing machine

Sewing faux leather with a sewing machine can be a rewarding yet challenging experience, especially for those looking to create stylish and durable products. Faux leather, often known as synthetic leather, is a versatile material prized for its aesthetic appeal and affordability compared to genuine leather. However, working with it requires certain techniques and tools to replicate the craftsmanship associated with leather goods.

Sewing faux leather requires patience with stitch choices as well. A straight stitch generally offers the greatest strength and simplicity, especially for seams. However, longer stitch lengths, around 3.5 to 4 mm, are advised to prevent perforation—that is, turning your material into a tear-away piece where the stitches act like a perforated edge. Experimenting on scrap pieces beforehand can fine-tune these settings. The challenge of working with faux leather extends to turning seams. This can be particularly difficult in bulkier projects like handbags. To ease this, trimming seam allowances and clipping corners can help in reducing bulk, making the process of turning much smoother. Also, consider topstitching for added durability and aesthetic appeal. This not only secures the seam allowances inside but also gives the edges a professional finish. Maintaining the aesthetic integrity of faux leather is pivotal, and this involves cleaning and caring for the material appropriately. Although generally less demanding than genuine leather, faux leather benefits from regular dusting and periodic cleaning with a damp cloth. Avoid harsh chemicals or abrasive cleaners that could damage the surface. Furthermore, while faux leather is generally resistant to water and stains, it’s not immune to cracking. Storing projects in a cool, dry place, away from direct sunlight, can prolong their life significantly. For items such as bags or jackets, occasional application of a faux leather conditioner can help maintain their suppleness and appearance. In summary, sewing faux leather with a sewing machine is an art that balances craftsmanship with the right tools and techniques. The satisfaction derived from creating faux leather products lies not only in the functionality and aesthetics but also in the sustainable approach of working with synthetic materials. By understanding and applying these techniques, crafters can confidently tackle faux leather projects, creating pieces that are not only beautiful but durable and environmentally conscious.

Sewing faux leather requires patience with stitch choices as well. A straight stitch generally offers the greatest strength and simplicity, especially for seams. However, longer stitch lengths, around 3.5 to 4 mm, are advised to prevent perforation—that is, turning your material into a tear-away piece where the stitches act like a perforated edge. Experimenting on scrap pieces beforehand can fine-tune these settings. The challenge of working with faux leather extends to turning seams. This can be particularly difficult in bulkier projects like handbags. To ease this, trimming seam allowances and clipping corners can help in reducing bulk, making the process of turning much smoother. Also, consider topstitching for added durability and aesthetic appeal. This not only secures the seam allowances inside but also gives the edges a professional finish. Maintaining the aesthetic integrity of faux leather is pivotal, and this involves cleaning and caring for the material appropriately. Although generally less demanding than genuine leather, faux leather benefits from regular dusting and periodic cleaning with a damp cloth. Avoid harsh chemicals or abrasive cleaners that could damage the surface. Furthermore, while faux leather is generally resistant to water and stains, it’s not immune to cracking. Storing projects in a cool, dry place, away from direct sunlight, can prolong their life significantly. For items such as bags or jackets, occasional application of a faux leather conditioner can help maintain their suppleness and appearance. In summary, sewing faux leather with a sewing machine is an art that balances craftsmanship with the right tools and techniques. The satisfaction derived from creating faux leather products lies not only in the functionality and aesthetics but also in the sustainable approach of working with synthetic materials. By understanding and applying these techniques, crafters can confidently tackle faux leather projects, creating pieces that are not only beautiful but durable and environmentally conscious.

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025