Seaming Machine Head Features and Applications in Modern Manufacturing Industries

Understanding Seaming Machine Heads The Heart of Efficient Fabric Seaming

The textile industry has seen tremendous advancements over the years, with machines becoming increasingly sophisticated and integrated into the production process. Among the most critical components of these innovations is the seaming machine head, a vital part in fabric handling, particularly in the garment sector. This article explores the significance, functionalities, and advancements in seaming machine heads, highlighting their impact on quality and efficiency in textile manufacturing.

What is a Seaming Machine Head?

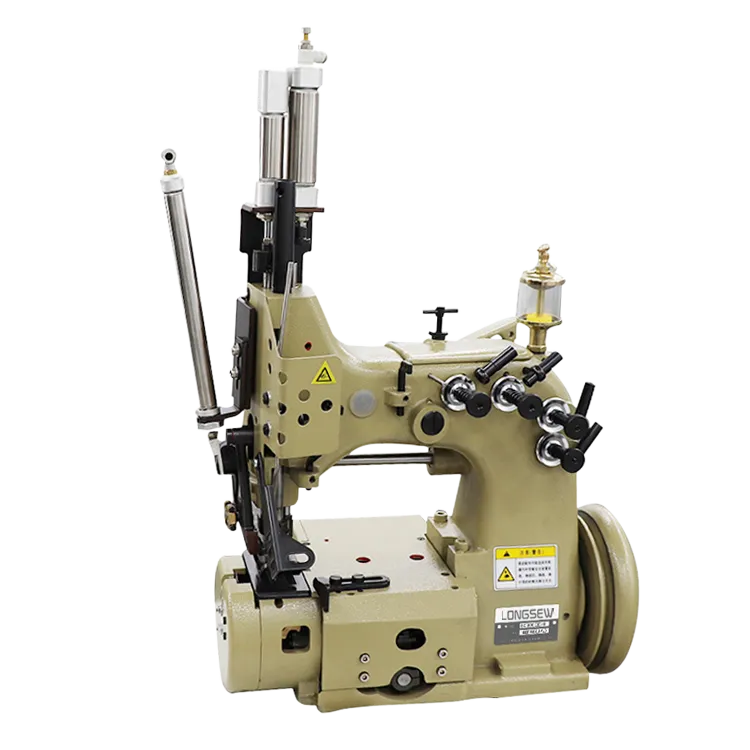

A seaming machine head is the part of a sewing machine responsible for the actual stitching process. It includes a needle mechanism, thread tensioning systems, and often a feeding mechanism that guides the fabric through the machine. The precision of these components directly influences the quality of seams produced, impacting the durability, appearance, and overall finish of the garments.

Importance of Seaming Machine Heads

The seaming machine head plays a significant role in determining the productivity and efficiency of a sewing operation. High-quality seams are essential for the integrity of the textile product, as they not only affect the style and look of the garment but also its fit and durability. In today’s competitive market, manufacturers are constantly seeking to improve the speed and accuracy of their sewing processes, making the choice of a high-performance seaming machine head crucial.

Types of Seaming Machine Heads

Seaming machine heads come in various types, each designed for specific applications

1. Lockstitch Heads The most common type, lockstitch machines use two threads – one from the top and one from the bottom – to create a stitch. They are widely used in clothing production due to their durability and versatility.

seaming machine head

2. Chainstitch Heads These machines utilize a single thread and are favored for their flexibility. They are often employed for materials that require stretch, such as athletic wear.

3. Overlock Heads These are specially designed to finish edges and prevent fraying. They are essential in the production of garments where seams need to be both secure and aesthetically pleasing.

4. Flatlock Heads Used for joining two pieces of fabric flatly, these are perfect for making seams that are less bulky and more comfortable against the skin, commonly used in activewear.

Advancements in Seaming Machine Technology

Recent advancements in seaming machine heads have transformed the landscape of textile manufacturing. Automation and computerization have introduced features like programmable stitching patterns, automatic thread cutting, and precise tension adjustments. Such innovations enhance the speed and accuracy of seaming, reduce material waste, and minimize human error. Moreover, the integration of advanced sensors allows for real-time monitoring of the sewing process, enabling immediate adjustments to maintain optimal performance.

The introduction of artificial intelligence in seaming technology is another groundbreaking development. AI-driven systems can analyze sewing patterns and detect anomalies, improving quality control. This leads to significant time savings and a reduction in defective products, ultimately benefiting manufacturers by minimizing costs associated with returns and rework.

Conclusion

Seaming machine heads are indispensable components in the textile industry, directly influencing the quality and efficiency of fabric seaming. Understanding their functions, types, and the latest technological advancements can help manufacturers make informed decisions, leading to improved production processes. As the industry continues to evolve, the development of more sophisticated seaming machine heads will undoubtedly play a pivotal role in meeting the growing demands for high-quality, durable, and stylish textile products. For businesses, investing in the right seaming technology is not just a choice; it is a necessity for staying competitive in a fast-paced market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025