fibc twin needle machine

Understanding the FIBC Twin Needle Machine A Game Changer for Bulk Bag Manufacturing

In the world of industrial manufacturing, efficiency and precision are key elements that drive productivity and product quality. One such innovation that has significantly impacted the manufacturing of Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, is the twin needle sewing machine. This advanced sewing technology has become essential in the production of FIBCs, ensuring that these bags can withstand the rigors of transportation and storage while containing various materials, from agricultural products to chemicals.

What is FIBC?

Flexible Intermediate Bulk Containers are large, flexible bags made from woven polypropylene. They are designed to hold and transport dry, bulk materials efficiently. FIBCs are widely used in various industries, including agriculture, pharmaceuticals, and construction, due to their lightweight nature, durability, and ability to hold substantial quantities of goods.

The Importance of Quality Sewing in FIBC Production

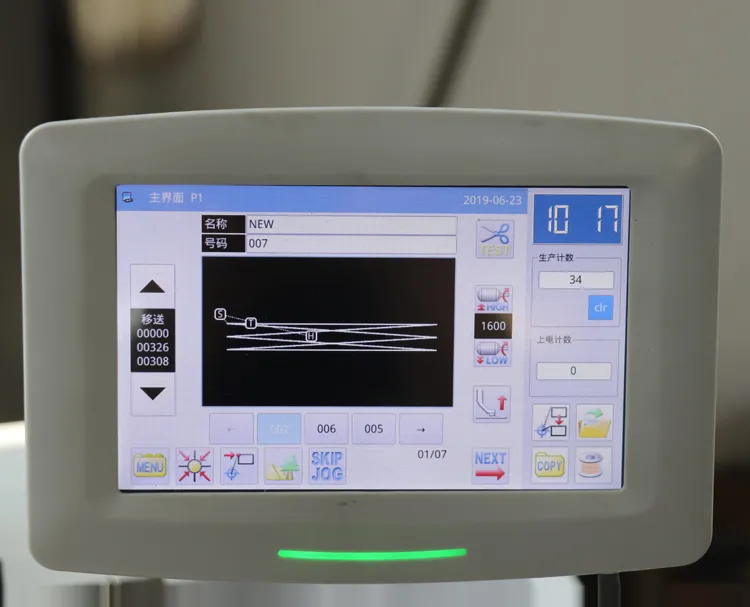

The sewing of FIBCs is a critical step in the manufacturing process. A well-constructed bulk bag must possess strong, durable seams that can carry heavy loads without tearing or splitting. This is where the twin needle sewing machine comes into play. The twin needle design allows for two lines of stitching simultaneously, significantly enhancing the seam strength compared to standard single needle machines.

Advantages of the Twin Needle Sewing Machine

2. Enhanced Stability The symmetry of the double stitch not only improves the strength of the seam but also provides better stability to the structure of the bag. This is particularly important when FIBCs are filled and transported, ensuring that the bags do not distort under pressure.

fibc twin needle machine

3. Efficiency and Speed By sewing two lines at once, twin needle machines reduce the overall sewing time per bag. This efficiency translates into higher production rates and reduced labor costs, positively impacting the bottom line for manufacturers.

4. Versatility Twin needle machines can be adjusted to work with different thread types and fabric weights, making them suitable for various applications within the FIBC manufacturing process. Whether it’s producing bags for lightweight agricultural products or heavy-duty construction materials, the machine's adaptability is a significant advantage.

5. Reduced Thread Consumption Interestingly, using a twin needle sewing machine can lead to lower thread usage because the machine's design allows for tighter seams, minimizing the amount of excess thread required for production.

Maintenance and Operation Considerations

While the benefits of the twin needle machine are clear, operators must be aware of specific maintenance and operational practices to ensure longevity and optimal performance. Regular cleaning, timely lubrication, and periodic inspections of the machine’s components are essential to prevent wear and tear. Additionally, training operators in proper threading techniques and tension adjustments can greatly reduce the risk of sewing defects and machine malfunctions.

Conclusion

As industries continue to seek ways to improve efficiency and product quality, the role of advanced sewing technologies like the FIBC twin needle sewing machine becomes increasingly important. By facilitating the production of stronger, more durable bulk bags, these machines not only enhance the quality of FIBCs but also contribute to a more streamlined manufacturing process. For manufacturers looking to stay competitive in the bulk bag industry, investing in a twin needle sewing machine is a step toward achieving greater operational effectiveness and product reliability.

With the ongoing evolution of manufacturing technologies, embracing such innovations is crucial for sustaining growth and meeting market demands. In the likely event of increasing requirements for higher quality and more efficient production methods, the FIBC twin needle sewing machine stands out as a vital asset in the journey toward excellence in bulk bag manufacturing. As we move forward, it will be exciting to see how such advancements continue to shape the fabric of the industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025