jumbo bag sewing machinery

The Importance of Jumbo Bag Sewing Machinery in Modern Manufacturing

In the fast-paced world of manufacturing, particularly in industries such as agriculture, construction, and food packaging, the demand for durable and efficient packaging solutions is at an all-time high. One of the most effective solutions for this demand is the jumbo bag, also known as a flexible intermediate bulk container (FIBC). These bags are designed to hold large quantities of product, ranging from granules and powders to agricultural produce, and their effectiveness is primarily reliant on high-quality jumbo bag sewing machinery.

Jumbo bags are made from woven polypropylene fabric, which makes them both lightweight and strong, allowing them to carry loads of up to 2 tons or more. The sewing of these bags is a critical process, as it ensures the structural integrity and reliability of the bag. This is where specialized jumbo bag sewing machinery comes into play. These machines are engineered to handle the unique challenges associated with sewing heavy-duty fabric, providing a robust solution that meets the rigorous demands of modern manufacturing.

One of the key advantages of utilizing jumbo bag sewing machinery is the speed and efficiency it brings to production lines. With advancements in technology, these sewing machines are capable of producing bags at a remarkably high rate while maintaining precision stitching. This increased productivity not only reduces manufacturing costs but also allows businesses to meet tight deadlines and fulfill large orders more efficiently. In a competitive market, this can be a significant advantage, helping businesses stay ahead of their rivals.

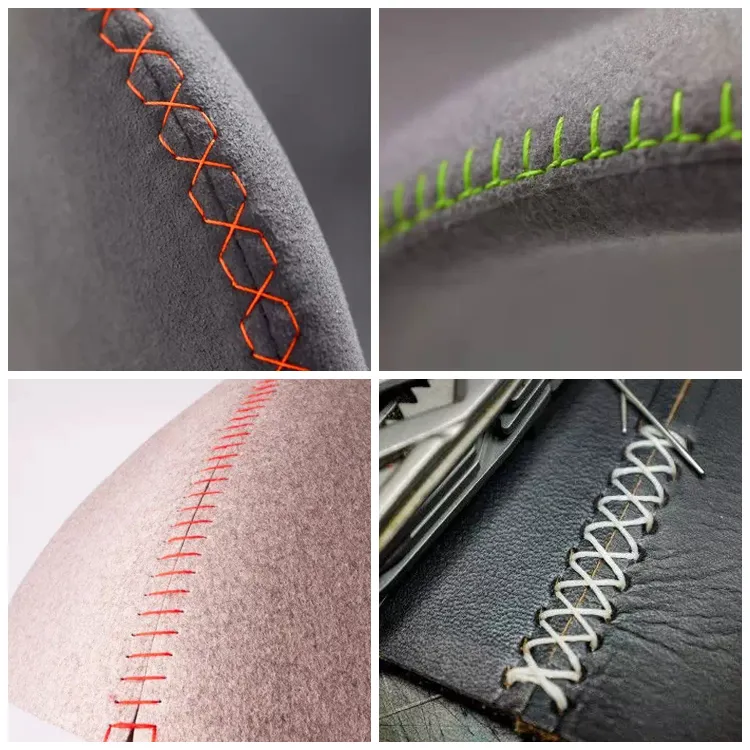

Another important aspect of jumbo bag sewing machinery is its versatility. Many of these machines come equipped with adjustable settings, allowing manufacturers to customize the sewing process according to the specific requirements of different bag designs. Whether it’s modifying the stitch type, adjusting thread tension, or changing the bag size, the right sewing machine can easily accommodate these variations. This adaptability is crucial for businesses looking to diversify their product offerings and cater to a wider range of clients.

jumbo bag sewing machinery

Moreover, modern jumbo bag sewing machinery is designed with user-friendly interfaces and automated features that simplify the sewing process. Operators can easily program the machines, resulting in a faster and more consistent output. Additionally, many machines are built with safety features to protect the operators, making the entire sewing environment safer and more productive.

The quality of the final product is paramount in any manufacturing process, and this holds true for jumbo bags. High-quality sewing machines ensure that bags are stitched with precision, preventing defects that could lead to failures in the field. This reliability is essential, as compromised bags can result in product loss and safety hazards. Investing in top-notch jumbo bag sewing machinery not only enhances product quality but also improves the overall reputation of the manufacturing company.

As the global economy grows and the demand for bulk packaging rises, the role of jumbo bag sewing machinery will only become more critical. Companies looking to streamline their operations and improve efficiency should prioritize investing in the latest sewing technology. By doing so, they can ensure they meet customer expectations while maintaining high standards of quality.

In conclusion, jumbo bag sewing machinery is an indispensable asset in the manufacturing landscape. Its ability to enhance production speed, flexibility, and product quality makes it a vital tool for any company involved in the production of bulk packaging. As industries continue to evolve, those who invest in reliable sewing machinery will undoubtedly lead the way in innovation and customer satisfaction. The future of packaging lies in automation and efficiency, making the choice of sewing machinery a cornerstone of operational success.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025