Innovative Sewing Techniques Using Double Chain Stitch Machines for Enhanced Crafting and Durability

The Double Chain Stitch Sewing Machine An Essential Tool for Seamstresses

Sewing machines have revolutionized the way we create and mend fabric, and among the various types available, the double chain stitch sewing machine stands out for its unique features and applications. This machine is especially valued in the garment industry for its efficiency and durability. In this article, we will explore the functionality, advantages, and applications of the double chain stitch sewing machine.

Functionality

The double chain stitch sewing machine is distinguished by its ability to create a stitch that consists of two interlocking threads. It operates using two needle threads and a single looper thread, which forms a chain on the underside of the fabric. This unique stitch construction allows for a great deal of stretch, making it ideal for sewing elastic materials or fabrics that require flexibility, such as knits and activewear.

The machine is equipped with two needles set parallel, which allows for two rows of stitching simultaneously. This feature not only enhances the strength of the seams but also increases the overall sewing efficiency. The double chain stitch is characterized by its neat appearance on both the front and back sides, which is particularly important in garment manufacturing where aesthetics play a crucial role.

Advantages

One of the primary advantages of the double chain stitch sewing machine is its durability. The chain stitch is considerably stronger than a single thread stitch, making it less likely to unravel over time. This quality is particularly beneficial in heavy-use items such as denim jeans, workwear, or outdoor gear that must withstand wear and tear.

Another significant advantage is its ability to handle stretchy fabrics. The double chain stitch allows for movement without breaking the seam, a feature not all sewing machines can offer. This makes it a favored choice for sportswear and comfort-focused clothing lines.

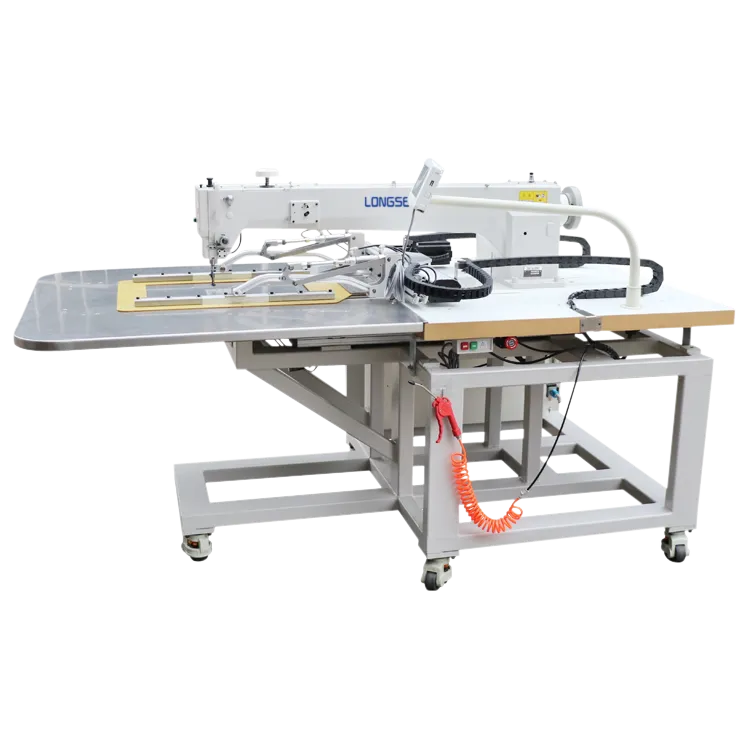

double chain stitch sewing machine

Additionally, the double chain stitch sewing machine is relatively easy to operate. Even those with limited sewing experience can quickly become proficient in its use. There is also a wide range of attachments and modifications available, allowing users to customize the machine for specific tasks or projects.

Applications

The double chain stitch sewing machine finds its primary application in the fashion and garment manufacturing industries. It is widely used for seaming, topstitching, and binding in the production of various clothing items, including shirts, dresses, pants, and activewear. Its ability to create a neat finish on both sides makes it invaluable in creating high-quality garments that look professional.

Moreover, it is commonly utilized in industrial settings where high-speed sewing is a requirement. The machine is capable of producing large quantities of garments quickly, significantly boosting productivity in a factory setting.

Beyond garment production, the double chain stitch is also employed in home sewing projects, particularly when seaming fabrics that require a durable and stretchy stitch. Hobbyists and craft enthusiasts appreciate the versatility of the machine, as it can be used for various sewing applications, from repairing clothing to creating custom designs.

Conclusion

The double chain stitch sewing machine is an essential tool for both professional seamstresses and enthusiastic hobbyists. Its ability to create strong, flexible seams makes it particularly useful in the fashion industry, while its ease of use has made it accessible to sewers of all skill levels. Whether you are a professional looking to enhance your production capabilities or a beginner interested in exploring new sewing techniques, this machine is sure to provide the durability and efficiency needed to bring your fabric creations to life. Embracing the double chain stitch sewing machine means embracing a tradition of quality craftsmanship and creative possibility.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025