Exploring the Benefits and Applications of Industrial Chain Stitch Machines in Modern Manufacturing Processes

Understanding the Industrial Chain Stitch Machine A Key Element in Textile Production

The industrial chain stitch machine plays a vital role in the textile and garment industry, renowned for its efficiency and versatility. In the realm of garment manufacturing, the ability to create durable and high-quality stitches is paramount, and chain stitch machines excel in this aspect. This article will explore the intricacies of chain stitch machines, their various applications, and their impact on modern manufacturing practices.

What is a Chain Stitch Machine?

A chain stitch machine operates using a looped stitch formation, where a single thread is interlocked with the fabric. Unlike lockstitch machines that use two threads (one for the top and one for the bobbin), chain stitch machines mainly utilize one continuous thread to create a series of interlocking loops. This design not only allows for faster sewing speeds but also makes them ideal for specific tasks like hemming, seaming, and decorative stitching.

Advantages of Chain Stitch Machines

1. Speed and Efficiency Chain stitch machines are engineered for high-speed operation, accommodating the demands of large-scale production. This efficiency significantly reduces the time required for sewing, allowing manufacturers to meet tight deadlines while maintaining quality.

2. Flexibility These machines are versatile and can be used for a variety of fabric types and weights. Whether dealing with lightweight chiffon or heavier denim, chain stitch machines can adapt to different materials, making them indispensable in a multi-fabric environment.

3. Durability of Stitches The nature of the chain stitch promotes stretchability, making it particularly suitable for garments that require a degree of elasticity, such as athletic wear and swimwear. The stitches are less prone to breaking, ensuring longer-lasting seams that can withstand wear and tear.

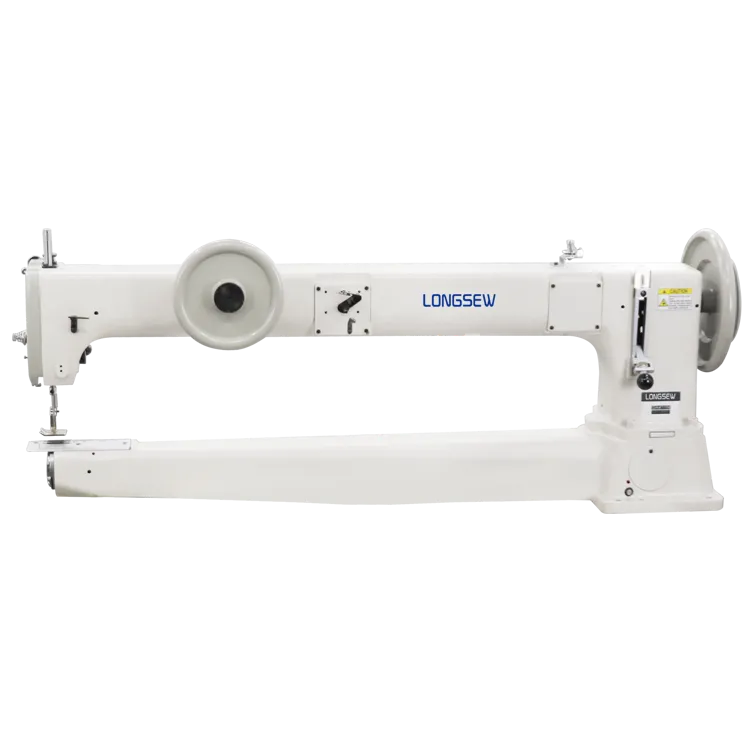

industrial chain stitch machine

4. Cost-Effectiveness While the initial investment in machinery may be significant, the efficiency and durability of chain stitches translate into lower production costs in the long run. The ability to produce high volumes of quality garments quickly leads to increased profits for manufacturers.

Applications in the Textile Industry

Chain stitch machines find broad applications across a range of textile products. They are particularly favored in the production of

- Sportswear and Activewear The flexibility and durability of chain stitches cater perfectly to the demand for comfortable and long-lasting sports apparel.

- Jeans and Denim Chain stitches are commonly used for hems and seams in denim fabrication, providing both strength and an authentic look.

- Home Textiles From curtains to bed linens, chain stitch machines are instrumental in producing various home textile products, ensuring both functional and aesthetic quality.

Conclusion

In conclusion, the industrial chain stitch machine serves as an essential tool in the modern textile and garment manufacturing landscape. Its speed, efficiency, and versatility cater to the ever-evolving demands of the industry, facilitating the creation of a wide array of high-quality garments. As the fashion world continues to prioritize both durability and style, the chain stitch machine stands out as a backbone of production, ensuring that manufacturers can keep pace with trends while maintaining exemplary standards. Investing in advanced chain stitch technology is not merely about acquiring equipment; it represents a strategic move towards enhancing productivity and achieving excellence in garment manufacturing.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025