industrial overlocker prices

Understanding Industrial Overlocker Prices Factors and Trends

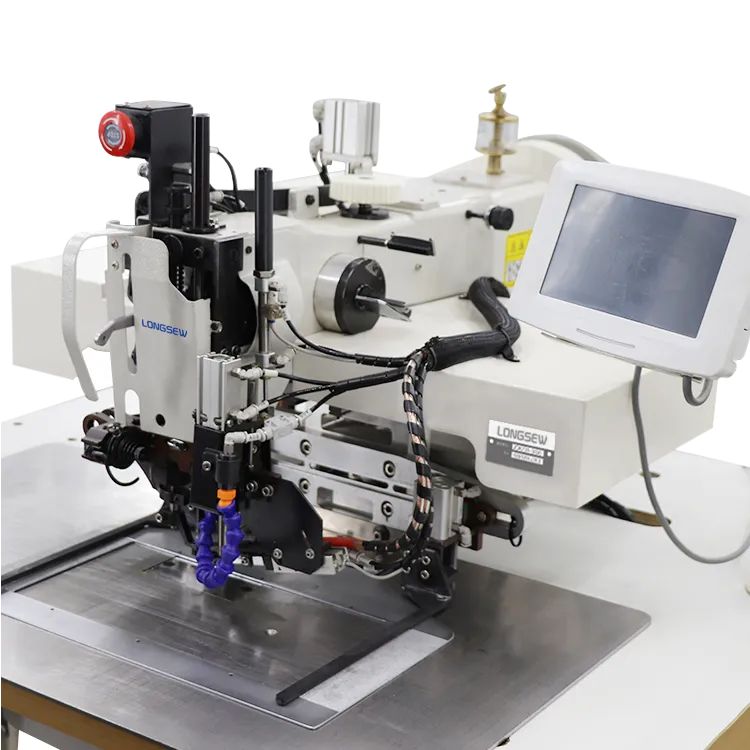

Industrial overlockers are essential machines in the textile and garment industry, used primarily for sewing seam edges and preventing fabric fraying. As businesses seek to improve production efficiency and ensure high-quality finishes, understanding the pricing of industrial overlockers becomes increasingly important. This article delves into the factors influencing industrial overlocker prices and current market trends.

Factors Influencing Prices

1. Brand Reputation The brand of the overlocker significantly affects its price. Established brands like Juki, Brother, and Janome often command higher prices due to their renowned reliability, advanced technology, and robust customer support. Newer or less recognized brands may offer more affordable options, but potential buyers should weigh the risks concerning quality and durability.

2. Machine Features and Technology Modern industrial overlockers come equipped with a variety of features such as automatic threading, adjustable stitch lengths, and differential feed settings. Machines with more advanced features tend to be priced higher. For example, a basic model with limited functionality may start at around $1,000, whereas a high-end model with advanced capabilities can exceed $4,000.

3. Number of Threads Overlockers come in various thread configurations—two, three, four, or even five threads. Machines with more threads allow for greater versatility in stitch types and are generally more complex and expensive. A four-thread overlocker, which is a popular choice for most garment production, typically falls within the mid-range price bracket.

4. Durability and Build Quality Industrial overlockers are designed for continuous use in a production environment, and their longevity can impact their pricing. Higher-quality machines made from durable materials may require a higher initial investment but can lead to lower operational costs in the long run, as they are less prone to breakdown and require less frequent repairs.

industrial overlocker prices

5. Country of Manufacture The place where the machine is manufactured can also influence pricing. Machines made in countries with higher labor and production costs tend to be more expensive. Conversely, overlockers produced in regions with lower manufacturing costs may be priced more competitively, but it’s crucial to evaluate their performance and longevity.

Market Trends

As of late 2023, the industrial overlocker market has seen a significant movement towards automation and smart technology. Manufacturers are integrating computerized systems into their machines to enhance usability and efficiency. These upgraded models often come at a premium, reflecting the market’s shift towards sophisticated solutions for productivity.

Additionally, sustainability has become a growing concern in the textile industry. Many businesses are now looking for overlockers that are energy-efficient and use eco-friendly materials. Consequently, machines that meet these criteria may have a higher price point due to their perceived additional value.

The demand for customized features has also surged, prompting manufacturers to offer more modular options. Buyers can now choose specific attachments or functionalities based on their unique production needs, impacting overall cost structures.

Conclusion

Investing in an industrial overlocker requires a thorough understanding of the factors that influence pricing and a keen awareness of market trends. While the allure of low-priced machines may be tempting, it is essential to consider the long-term implications of quality and durability. As technology advances and consumer preferences evolve, it is crucial for businesses to stay informed about the best options available to suit their operational needs. Whether a startup or an established company, making informed choices regarding industrial overlocker purchases can lead to improved product quality and greater operational efficiency.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025