climbing rope sewng machine

The Role of Sewing Machines in Manufacturing Climbing Ropes

Climbing is an exhilarating sport that not only challenges our physical abilities but also tests our mental resilience. As climbers rely on safety equipment for protection, the quality of gear becomes paramount. Among the essential equipment, climbing ropes are critical for safety, and their manufacturing process is a fine blend of technology and craftsmanship. One invaluable tool in this process is the sewing machine, particularly specialized industrial sewing machines designed for heavy-duty fabrics, which play a significant role in the production of climbing ropes.

Understanding Climbing Ropes

Climbing ropes are designed to withstand extreme forces and harsh weather conditions. They are generally categorized into two main types dynamic and static ropes. Dynamic ropes are used for climbing and are engineered to stretch under load, absorbing impacts during falls. In contrast, static ropes have minimal stretch and are typically used for activities such as caving or rescue operations. Regardless of the type, climbing ropes need to be constructed with precision, durability, and safety in mind.

The Manufacturing Process

The manufacturing of climbing ropes involves several complex steps, and sewing machines become crucial at various stages. The raw materials used to produce climbing ropes are commonly synthetic fibers, such as nylon and polyester. These materials are chosen for their strength, durability, and resistance to abrasion, UV light, and moisture.

Once the fibers are processed into strands, they are twisted together to form the core and sheath of the rope. The core provides strength, while the sheath offers protection against wear and tear. After the rope has been braided or twisted together, the next crucial step is securing the ends of the rope to prevent fraying. This is where sewing machines come into play.

The Importance of Sewing Machines

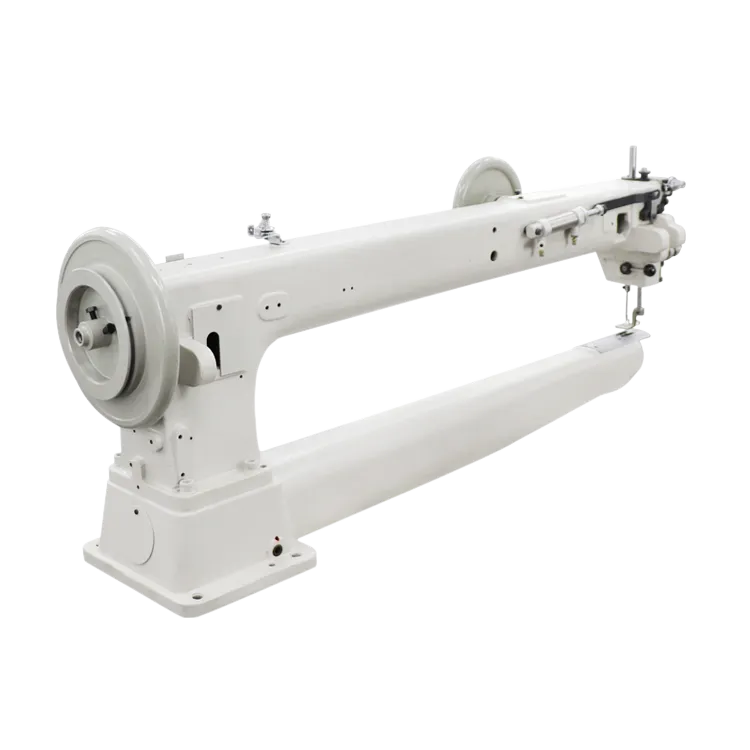

Industrial sewing machines used in climbing rope manufacturing are robust, capable of stitching through thick layers of heavy-duty materials. They are designed to create strong, reliable seams that can withstand significant tension. For instance, the ends of climbing ropes are often fitted with various types of terminations, such as loop splices or sewn eyes, to ensure they can be securely connected to safety harnesses or carabiners.

climbing rope sewng machine

The sewing process may involve multiple techniques, including zigzag stitching and bar tacking, which reinforce the stress points of the rope. Bar tacking, in particular, is crucial as it provides additional strength at critical junctions, ensuring that the rope maintains its integrity even under extreme loads.

Safety Standards and Testing

Manufacturers of climbing ropes are required to adhere to rigorous safety standards. This often involves testing the ropes for factors such as tensile strength, durability, and resistance to wear. The quality of the sewing is paramount in passing these tests, as a poorly executed seam can lead to catastrophic failure during use. As such, the sewing process is conducted under strict quality control protocols, with regular inspections of the machines and the final products to ensure compliance with industry standards.

Technological Advancements

Recent advancements in technology have further improved the efficiency and precision of sewing machines in the climbing rope industry. Automated sewing machines equipped with computer numerical control (CNC) systems can now execute intricate stitching patterns with minimal human intervention. These innovations allow for higher production rates while maintaining consistent quality, which is crucial for meeting the growing demand for climbing gear among enthusiasts.

Additionally, the integration of robotics and artificial intelligence in sewing processes is paving the way for greater accuracy and reduced labor costs. This technological evolution not only enhances production capabilities but also enables manufacturers to explore more complex designs and materials for climbing equipment.

Conclusion

In conclusion, sewing machines are a linchpin in the manufacturing of climbing ropes, ensuring that they meet the demanding safety requirements of climbers. With robust designs and advanced technology, these machines enable manufacturers to produce high-quality, reliable ropes that climbers depend on. As the climbing industry continues to grow, the importance of these machines and the craftsmanship behind climbing rope production will remain integral to ensuring the safety and performance of outdoor adventurers. The growing technological advancements promise even greater innovations, ensuring that climbers can rely on their gear as they tackle new heights.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025