Jan . 13, 2025 14:29

Back to list

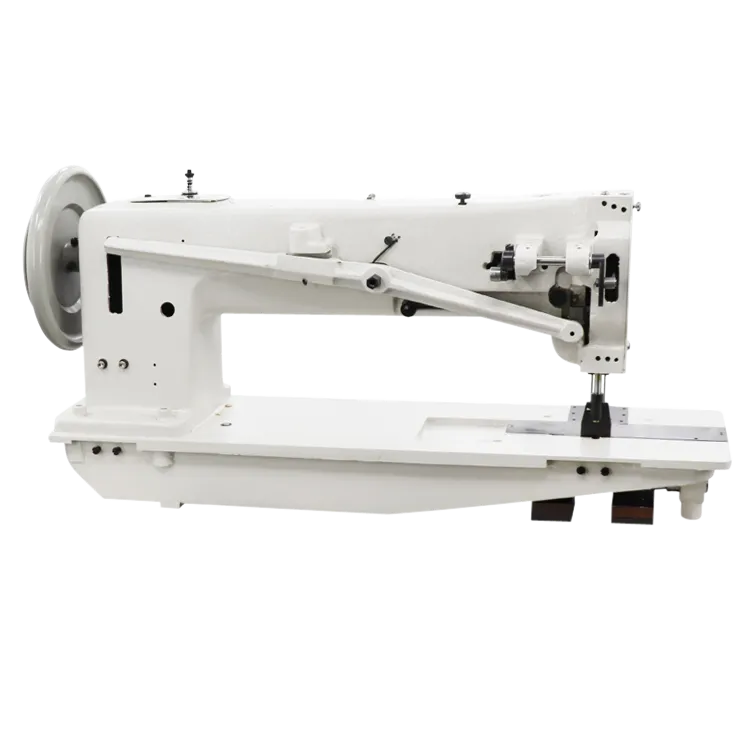

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

When it comes to selecting the right commercial double needle sewing machine, success in the textile industry relies on balanced expertise and skillful decision-making. This crucial equipment, a cornerstone for manufacturing companies, plays a vital role in meeting the swift production demands of modern businesses, especially in a competitive global market.

The credibility of these machines is further highlighted by their adaptability within various manufacturing processes. From denim jeans requiring robust and reinforced seams to intricate quilted fabrics in home textiles, a double needle sewing machine is an invaluable asset. This adaptability is crucial for businesses aiming to diversify their offerings without sacrificing quality or production speed. However, choosing the right machine should involve a careful assessment of specific business needs. Consider factors such as the types of materials commonly used, the complexity of the sewing patterns required, and the expected workload. Investing in training and regular maintenance further leverages these machines' potential, enhancing their longevity and operational efficiency. With an extensive range of models available, accessible expert opinions and reviews play an essential role in navigating these choices. Engaging with experienced operators and reading unbiased reviews on forums or trade publications can provide novice buyers with insights into machine performance and reliability under various conditions. In summary, investing in a commercial double needle sewing machine is a strategic move that aligns with both immediate production goals and long-term business growth. Combining substantial experience, industry expertise, recognized authority, and deep trust, these machines deliver an unparalleled blend of performance and value, making them indispensable in achieving competitive advantage and operational excellence in the textile industry.

The credibility of these machines is further highlighted by their adaptability within various manufacturing processes. From denim jeans requiring robust and reinforced seams to intricate quilted fabrics in home textiles, a double needle sewing machine is an invaluable asset. This adaptability is crucial for businesses aiming to diversify their offerings without sacrificing quality or production speed. However, choosing the right machine should involve a careful assessment of specific business needs. Consider factors such as the types of materials commonly used, the complexity of the sewing patterns required, and the expected workload. Investing in training and regular maintenance further leverages these machines' potential, enhancing their longevity and operational efficiency. With an extensive range of models available, accessible expert opinions and reviews play an essential role in navigating these choices. Engaging with experienced operators and reading unbiased reviews on forums or trade publications can provide novice buyers with insights into machine performance and reliability under various conditions. In summary, investing in a commercial double needle sewing machine is a strategic move that aligns with both immediate production goals and long-term business growth. Combining substantial experience, industry expertise, recognized authority, and deep trust, these machines deliver an unparalleled blend of performance and value, making them indispensable in achieving competitive advantage and operational excellence in the textile industry.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025