Cylinder Bed Sewing Machine Price | Industrial & Heavy Duty

Understanding the Value Proposition of Cylinder Bed Sewing Machines

In specialized industrial applications, the choice of sewing equipment significantly impacts productivity, precision, and the overall quality of finished goods. For complex three-dimensional items like footwear, bags, and automotive upholstery, the cylinder bed sewing machine price reflects not just the initial investment but also its inherent capabilities to handle challenging geometries and thick materials. These machines, specifically engineered with a narrow, cylindrical arm, excel where flatbed machines cannot reach, allowing for precise stitching inside hollow or tubular products. Their robust design and specialized feeding mechanisms make them indispensable for manufacturers prioritizing durability and intricate detailing in their product lines.

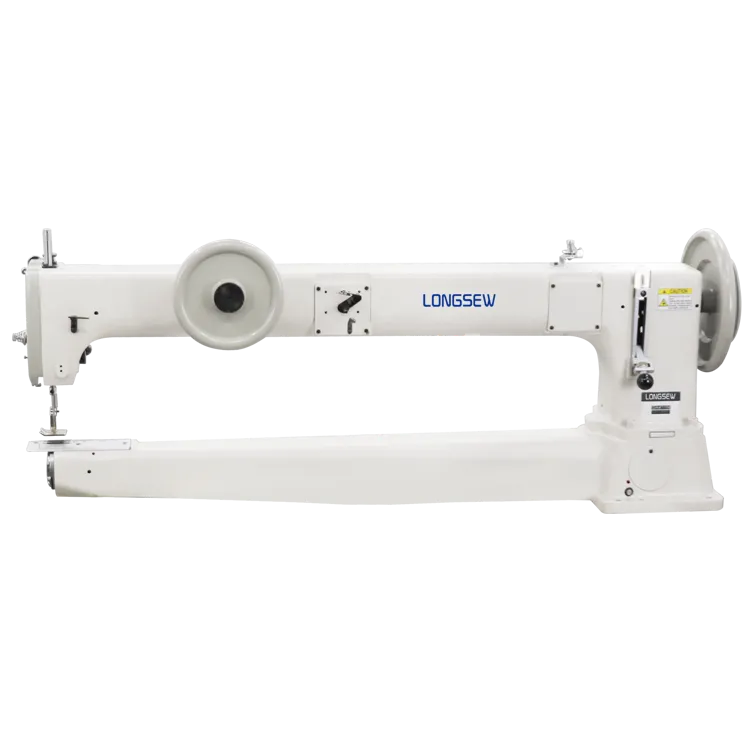

The demand for a high-quality cylinder bed sewing machine for sale continues to grow, driven by sectors requiring highly durable and meticulously stitched products. From the intricate construction of boots to the sturdy assembly of luggage, the performance of these machines is paramount. Key considerations for businesses evaluating the cylinder bed sewing machine price include not only the upfront cost but also the machine's longevity, maintenance requirements, and its adaptability to various materials and production volumes. Investing in a machine like the Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N ensures a return through enhanced operational efficiency and superior product quality, crucial for maintaining competitive advantage in today's demanding markets.

The Engineering Excellence of Cylinder Arm Sewing Machines

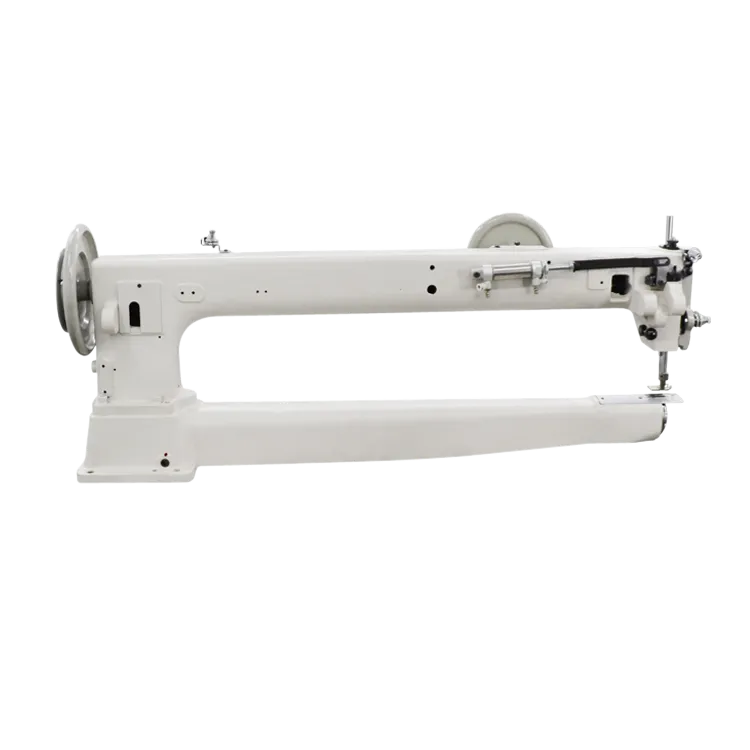

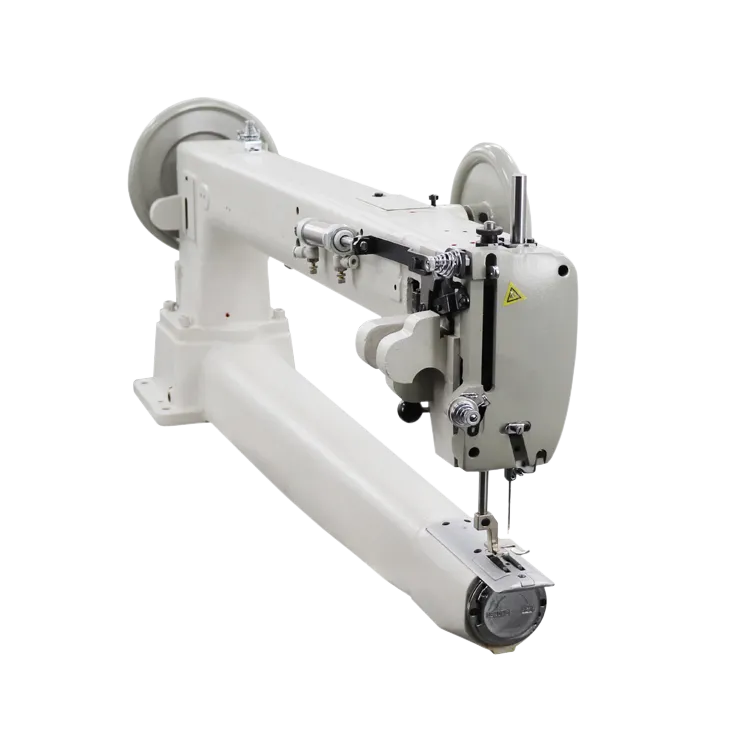

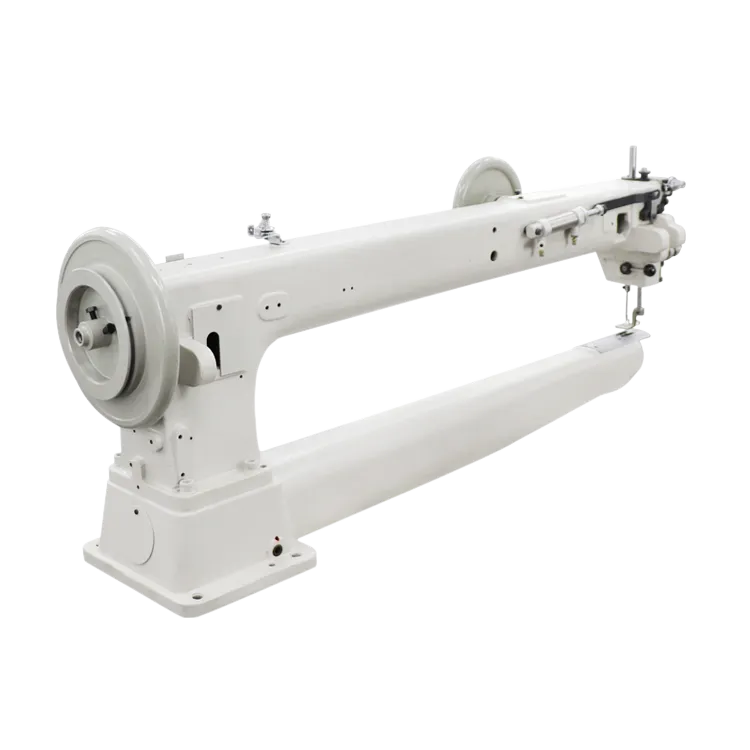

The design of a cylinder arm sewing machine is a marvel of industrial engineering, tailored specifically for the unique challenges of stitching three-dimensional objects. Unlike conventional flatbed machines, the narrow, elongated arm provides unparalleled access to confined spaces, such as the inside of a shoe or the corner of a bag. This design necessitates a precise manufacturing process, starting with high-grade steel and aluminum alloys chosen for their durability and resistance to wear under continuous operation. Components undergo rigorous processes like precision CNC machining, ensuring micron-level accuracy for moving parts, which is critical for consistent stitch quality and reduced friction.

Manufacturing protocols often adhere to international standards such as ISO 9001 for quality management, ensuring every unit meets stringent performance and reliability benchmarks. Each component, from the feed dog to the bobbin case, is meticulously tested for material integrity and dimensional accuracy. The typical lifespan of a well-maintained industrial cylinder arm sewing machine can exceed 15-20 years, making it a sustainable long-term asset. For instance, the Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine GA411N features a robust construction designed to withstand the rigors of heavy-duty material processing, including tough leathers and multiple layers of synthetic fabrics. This engineering focus translates directly into the overall cylinder bed sewing machine price, reflecting superior build quality and extended operational life.

Technical Specifications and Performance Benchmarks

When evaluating the cylinder bed sewing machine price, a thorough review of technical specifications is essential. Performance parameters dictate a machine's capability to handle specific materials and production volumes. Key aspects include the arm length, which determines the reach into complex workpieces; stitch length and presser foot lift, critical for managing varying material thicknesses; and the type of feeding mechanism, such as unison or compound feed, which ensures consistent material handling for multi-layered or slippery fabrics. These technical nuances are integral to selecting the right machine for specialized tasks.

Below is a comparison table outlining typical specifications for various industrial cylinder arm machines, highlighting how different features contribute to their overall performance and influence the cylinder bed sewing machine price. The Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine GA411N stands out with its extended arm and robust construction, ideal for products like boots and barrel-shaped items.

These specifications directly influence the machine's efficiency, the quality of the output, and ultimately, the profitability of production lines. A higher-end industrial cylinder sewing machine with advanced features will naturally command a higher initial cylinder bed sewing machine price, but it offers unparalleled precision, durability, and versatility for handling specialized materials like heavy leather and multi-layered synthetics.

Applications and Industry Adaptability

The versatility of the typical cylinder arm sewing machine makes it a cornerstone in numerous manufacturing sectors. Its primary strength lies in its ability to navigate curves, tight corners, and tubular shapes that are impractical for flatbed machines. This makes them indispensable in the production of high-end footwear, including boots, athletic shoes, and specialized orthopedic footwear, where intricate stitching around lasts is common. Beyond shoes, the leather cylinder arm sewing machine variant is crucial for crafting premium leather goods such as handbags, briefcases, wallets, and equestrian equipment, demanding both strength and aesthetic precision.

Furthermore, the automotive upholstery industry heavily relies on these machines for sewing car seats, dashboards, and convertible tops, where durable seams and precise finishing are critical for safety and comfort. Other applications include luggage, sports equipment, and even some apparel items with challenging contours. Industry trends indicate a growing demand for more automated and intelligent cylinder bed machines that integrate features like automatic thread trimming, programmable stitch patterns, and digital control interfaces. This evolution ensures that the industrial cylinder sewing machine remains at the forefront of specialized textile manufacturing, continually adapting to the increasing complexity and quality demands of global markets.

Advantages of Advanced Cylinder Bed Technology

The advantages of investing in a state-of-the-art heavy duty cylinder arm sewing machine extend far beyond mere functionality. These machines offer superior precision and control, allowing operators to achieve consistent, high-quality seams even on challenging materials and intricate designs. The long arm and cylindrical shape facilitate easier manipulation of large or convoluted workpieces, significantly reducing material handling time and operator fatigue. This ergonomic benefit translates directly into increased productivity and a more consistent output, directly impacting the long-term operational costs that mitigate the initial cylinder bed sewing machine price.

Furthermore, advanced models are equipped with powerful servo motors, offering precise speed control and excellent piercing power, essential for sewing through multiple layers of heavy-duty materials like leather, canvas, and industrial synthetics without stalling. The unison feed mechanism, combining needle, presser foot, and feed dog movement, ensures that all layers of fabric move together, preventing puckering and slippage, especially critical for applications requiring perfect alignment. This technological superiority ensures the longevity of the stitched product and enhances the brand's reputation for quality, making the investment in a premium industrial cylinder sewing machine a strategic decision for manufacturers aiming for excellence.

Manufacturer Comparison and Custom Solutions

Navigating the market for an industrial cylinder sewing machine requires careful consideration of various manufacturers, each offering distinct advantages in terms of technology, support, and specialization. Leading manufacturers often differentiate themselves through innovative features, build quality, and comprehensive after-sales service. When assessing the cylinder bed sewing machine price, it is crucial to look beyond the base cost and evaluate the total cost of ownership, which includes factors like spare parts availability, technical support responsiveness, and warranty periods. Reputable brands typically provide extensive training and readily accessible documentation, crucial for maximizing machine uptime and operator proficiency.

Many high-volume manufacturers and niche producers also benefit significantly from customized sewing solutions. While standard models cater to a broad range of applications, bespoke configurations can address very specific production challenges. This might involve modifications to the arm length, specialized presser feet, custom guides, or integration with automation systems to streamline specific processes. Collaborating with a manufacturer capable of delivering tailor-made machines ensures optimal performance for unique product requirements, enhancing efficiency and reducing the need for manual adjustments. For example, a manufacturer producing very long, cylindrical items might require an even longer arm than typical, an area where custom solutions for the heavy duty cylinder arm sewing machine prove invaluable.

Real-World Application Cases and Customer Insights

The practical utility of the Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N is best illustrated through its application in real-world scenarios. A leading boot manufacturer, challenged by the consistent stitching of tall, narrow boot shafts, reported a 30% increase in production efficiency after integrating the GA411N. The extended horizontal arm allowed for seamless manipulation of the boot shaft, ensuring uniform stitches without repositioning, a common bottleneck with standard machines. This led to a significant reduction in labor time and material waste, justifying the initial cylinder bed sewing machine price through rapid return on investment.

Another case involves a specialized bag producer creating large, cylindrical duffel bags. Previously, inconsistent stitching and difficulty reaching internal seams resulted in high rejection rates. Upon adopting the GA411N, the consistency of stitching improved dramatically, with defects plummeting by 40%. Operators praised the machine's robust feeding mechanism, which handled heavy canvas and multiple layers of webbing with ease, maintaining stitch integrity throughout the entire sewing process. These testimonials underscore the importance of selecting a purpose-built industrial cylinder sewing machine for specialized tasks, as its specific design advantages translate directly into measurable operational improvements and enhanced product quality, solidifying its value proposition.

Factors Influencing Cylinder Bed Sewing Machine Price & Purchasing Considerations

The cylinder bed sewing machine price is influenced by a multitude of factors, making it crucial for buyers to conduct thorough research. Core determinants include the machine's brand reputation, which often correlates with build quality and technological innovation. Machines from globally recognized manufacturers typically come with a higher price tag but offer superior reliability, access to genuine spare parts, and a more extensive support network. Features such as automatic functions (thread trimming, needle positioning), specialized feeding systems (unison feed, roller foot), motor type (servo vs. clutch), and the length and diameter of the cylinder arm also significantly impact cost. A heavy duty cylinder arm sewing machine designed for continuous industrial operation will naturally be priced higher than a lighter duty model.

When looking for a cylinder bed sewing machine for sale, consider its intended application and the materials it will process. For instance, a leather cylinder arm sewing machine designed specifically for thick leathers will have different specifications and a distinct price point compared to a general-purpose model. Furthermore, after-sales service, warranty coverage, and the availability of technical training are critical long-term considerations that add to the overall value, even if they contribute to a higher initial cylinder bed sewing machine price. Buyers should also inquire about customization options, which can optimize the machine for very specific production needs, potentially offering better long-term efficiency despite an increased upfront investment.

Trustworthiness & Support: Your Investment in Quality

Securing a reliable industrial cylinder sewing machine involves more than just the initial cylinder bed sewing machine price; it's about partnering with a supplier who stands behind their products. At Longsew, our commitment to quality is underscored by adherence to ISO 9001 standards, ensuring every Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine GA411N meets rigorous performance and safety criteria. Our machines are built for longevity, typically offering a robust operational life with proper maintenance, significantly reducing the total cost of ownership.

Frequently Asked Questions (FAQ)

-

Q: What is the typical delivery period for the GA411N?

A: Standard models of the GA411N typically have a lead time of 2-4 weeks, depending on current stock and order volume. Expedited shipping options may be available upon request. -

Q: What kind of warranty comes with the machine?

A: The GA411N comes with a comprehensive 1-year warranty covering manufacturing defects. Extended warranty options and service contracts are also available for continuous peace of mind. -

Q: Is technical support available after purchase?

A: Yes, we provide full technical support, including online troubleshooting, video tutorials, and readily available spare parts to ensure minimal downtime for your operations. Our expert technicians are ready to assist.

Conclusion

The strategic investment in a specialized cylinder bed sewing machine, particularly a robust model like the Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine GA411N, is a pivotal decision for manufacturers seeking to enhance quality, efficiency, and expand their production capabilities. While the initial cylinder bed sewing machine price requires careful consideration, its long-term value is realized through its unparalleled ability to handle complex geometries, thick materials, and deliver consistently precise stitches. By focusing on factors such as engineering quality, adaptable technical specifications, and comprehensive post-purchase support, businesses can ensure they acquire a machine that not only meets immediate production demands but also contributes significantly to their operational success and market competitiveness for years to come.

References

- ISO. (n.d.). ISO 9001: Quality management systems. International Organization for Standardization.

- Textile Industry Affairs. (2023). Advancements in Industrial Sewing Machine Technologies.

- Leather Manufacturers Council. (2022). Precision Stitching for High-End Leather Goods.

- Footwear Technology Journal. (2021). Ergonomics and Efficiency in Boot Manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025