Automatic Pattern Sewing Machine: Precision & Industrial Efficiency

Industry Trends and the Rise of Automated Precision Sewing

The global textile and technical fabric manufacturing landscape is undergoing a significant transformation, driven by an escalating demand for higher precision, increased efficiency, and reduced labor costs. Traditional manual sewing methods, while foundational, often struggle to meet the stringent quality and output requirements of modern industrial applications. This evolution has spurred the widespread adoption of advanced automation solutions, with the automatic pattern sewing machine emerging as a pivotal technology. These sophisticated machines are redefining production capabilities across sectors ranging from automotive upholstery to heavy-duty lifting slings, enabling manufacturers to achieve unparalleled consistency and intricate design execution. The ability to program complex stitch patterns ensures repeatable quality, minimizing human error and material waste, which are critical factors in competitive B2B environments. This shift towards automation not only enhances productivity but also allows for greater design flexibility and product innovation, addressing the growing market need for highly specialized textile products.

In particular, the demand for robust and reliable industrial sewing solutions is booming within niche markets that require exceptional material strength and durability. Industries such as automotive, marine, aerospace textiles, and the production of industrial safety equipment increasingly rely on machines capable of handling thick, multi-layered materials with precise, high-tension stitching. The integration of digital control systems and advanced mechanics in modern automatic pattern sewing machines allows for exact stitch length, thread tension, and material feeding, crucial for maintaining structural integrity in applications where failure is not an option. This technological leap addresses the need for faster turnaround times without compromising on the meticulous quality standards demanded by industrial clients, positioning automatic pattern sewing technology as an indispensable asset for manufacturers striving for operational excellence and market leadership.

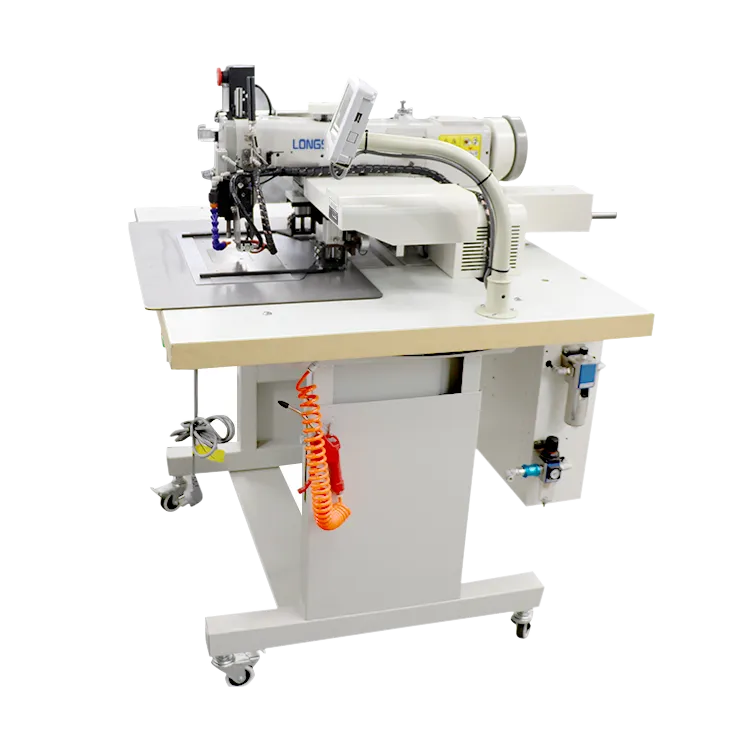

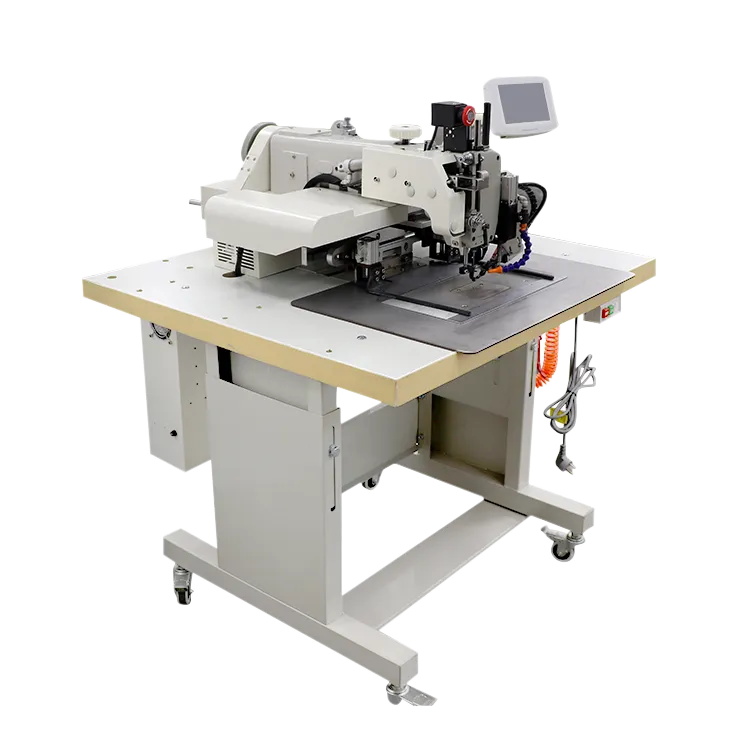

Introducing the Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

At the forefront of this industrial revolution is the Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020, a testament to engineering excellence in automated sewing technology. Specifically engineered for demanding applications, this machine is a robust solution for manufacturing high-strength textile products, including lifting slings, safety harnesses, and heavy-duty industrial webbing. Its advanced computerized control system allows for the precise programming and execution of complex stitching patterns, ensuring uniform and exceptionally strong seams even with challenging materials. The LS273-3020 excels in handling thick fabrics and multiple layers, thanks to its powerful servo motor, optimized feed mechanism, and high needle penetration force. This capability is vital for products where structural integrity and load-bearing capacity are paramount, directly contributing to product reliability and user safety in critical applications.

The design philosophy behind the LS273-3020 emphasizes durability, operational efficiency, and user-friendliness. Key features include an expansive sewing area of 300mm x 200mm, accommodating large patterns and bulky materials with ease. Its intuitive touchscreen interface simplifies pattern creation and recall, enabling operators to switch between different production tasks swiftly. This efficiency is further enhanced by its high-speed stitching capabilities and automatic thread trimming, which significantly reduce cycle times and material waste. For manufacturers focused on producing high-quality heavy-duty textiles, the LS273-3020 represents a strategic investment that delivers tangible benefits in terms of productivity gains, consistent product quality, and reduced manual labor requirements. It is a prime example of how an automatic pattern sewing machine can elevate manufacturing standards.

Precision Manufacturing Process and Quality Assurance

The superior performance and longevity of an automatic pattern sewing machine like the LS273-3020 are rooted in a meticulously engineered manufacturing process that prioritizes precision, material integrity, and rigorous quality control. The production of core components, such as the machine frame, needle bar, and feeding mechanism, involves advanced manufacturing techniques. High-grade steel and aerospace-grade aluminum alloys are selected for their strength and durability, undergoing processes like precision CNC machining to achieve exact tolerances. Components critical for movement and power transmission, such as gears and shafts, are often hardened through heat treatment or specialized coatings to resist wear and corrosion, ensuring a long service life and consistent operation under continuous heavy loads.

Quality assurance is integrated at every stage, from raw material inspection to final assembly and testing. Components are subjected to stringent quality checks, including dimensional accuracy verification using coordinate measuring machines (CMMs) and material integrity tests. The assembly process follows ISO 9001 certified standards, emphasizing meticulous alignment and calibration of all moving parts. Before dispatch, each LS273-3020 undergoes comprehensive operational testing, simulating real-world production conditions. This includes continuous stitching tests with various materials, verification of pattern accuracy, and checks on motor performance, thread tension consistency, and automatic functions. These rigorous internal quality protocols ensure that every automatic pattern sewing machine delivered adheres to the highest industry standards, often exceeding general ANSI or international machinery safety guidelines, and is prepared for immediate, reliable service in demanding industrial environments.

Technical Specifications and Performance Benchmarks

Understanding the detailed technical specifications of an automatic pattern sewing machine is crucial for B2B decision-makers to assess its suitability for their specific production needs. The Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020 is engineered with performance parameters that ensure superior output and operational efficiency for heavy-duty applications. Its capabilities extend beyond simple straight stitches, offering intricate pattern programming for complex designs required in safety equipment, automotive components, and technical textile products. The interplay of its large sewing area, high-speed operation, and powerful servo motor ensures it can consistently deliver high-quality seams even on materials up to 15mm thick, making it ideal for multi-layer fabric assembly where precision and strength are paramount.

| Parameter | Specification (LS273-3020 Typical) | Industrial Average |

|---|---|---|

| Sewing Area (X x Y) | 300mm x 200mm | Approx. 200mm x 100mm to 500mm x 300mm |

| Max. Sewing Speed | 2,500 rpm | 1,500 - 3,000 rpm |

| Stitch Length | 0.1 - 12.7 mm | 0.1 - 10 mm |

| Max. Presser Foot Lift | 20 mm | 15 - 20 mm |

| Needle System | DPx17 (heavy duty) | Various, often DPx17 for heavy duty |

| Thread Type | Nylon, Polyester, Kevlar (V69 - V207) | V69 - V207 (Tex 70 - Tex 210) |

| Motor Type | Integrated Servo Motor | Servo Motor (common in modern industrial machines) |

| Control System | Computerized with Touchscreen HMI | PC-based or Integrated PLC |

This table highlights the LS273-3020's competitive edge in key performance metrics, demonstrating its capacity for handling demanding industrial applications. The larger sewing area is particularly beneficial for products like automotive seating components, where an auto upholstery sewing machine needs to accommodate sizable pieces, or for large lifting slings. The high maximum stitch length allows for powerful reinforcement stitches, while the substantial presser foot lift is essential for manipulating very thick or multi-layered materials. These parameters, combined with robust construction, position the LS273-3020 as a leading choice for manufacturers seeking an efficient and precise automatic sewing machine industrial solution.

Diverse Application Scenarios and Key Advantages

The versatility of an automatic pattern sewing machine extends across a broad spectrum of industrial applications, making it an invaluable asset for businesses aiming to optimize their production processes. While the LS273-3020 is specifically designed for heavy-duty tasks like manufacturing slings and safety equipment, its underlying technology, a sophisticated automatic sewing machine industrial platform, is highly adaptable. It finds extensive utility in the automotive industry for producing high-quality interiors, seat components, and airbags, where precise, repeatable stitching is critical for both aesthetics and safety. For instance, an auto upholstery sewing machine variant of this technology ensures flawless seams on leather, vinyl, and other composite materials, improving the finish and durability of vehicle interiors, whether it's an auto upholstery sewing machine for sale or integrated into a full production line.

Beyond automotive, these machines are integral to the production of various technical textiles, including tents, awnings, protective covers, and even specialized filtration media. The ability to program intricate patterns ensures that complex shapes and reinforcements can be stitched accurately and consistently, which is often impossible with manual methods. Advantages include significant increases in production speed, reducing overall manufacturing costs and enabling faster response to market demands. The consistent quality delivered by automated systems minimizes defects, leading to less material waste and fewer product recalls, thereby enhancing brand reputation and customer satisfaction. Furthermore, ergonomic benefits for operators, reducing repetitive strain injuries, also contribute to a more efficient and sustainable production environment, making this an ideal automatic sewing machine industrial solution.

Advanced Technological Capabilities and Customization Options

The technological prowess of a modern automatic pattern sewing machine is a significant differentiator in today’s competitive manufacturing landscape. Key innovations include highly responsive servo motor control, which provides precise needle positioning and instantaneous speed adjustments, essential for complex curves and sharp corners in patterns. Features such as automatic thread trimming and automatic presser foot lifting further streamline operations, eliminating manual steps and reducing non-sewing time. Many advanced systems incorporate digital pattern creation software, allowing designers to virtually draft and test patterns before physical production, greatly accelerating prototyping and reducing material waste. Some sophisticated units, like the LS273-3020, also support barcode scanning for instant pattern recall, enhancing efficiency in high-mix, low-volume production environments.

Beyond standard features, reputable manufacturers offer extensive customization options to tailor an automatic pattern sewing machine to specific client requirements. This includes adapting the sewing area dimensions to accommodate unusually large or small products, integrating specialized clamps or jigs for unique material handling, or configuring the machine for specific thread types and needle sizes required for extreme-duty applications. For an auto upholstery sewing machine walking foot, for example, adjustments can be made to optimize the feed mechanism for delicate or slippery automotive fabrics, ensuring consistent material transport without marring the surface. The ability to customize ensures that the machine perfectly integrates into existing production lines and addresses unique challenges posed by specialized materials or complex product geometries, maximizing return on investment for the discerning buyer.

Ensuring Trustworthiness: Service, Support, and Testimonials

For B2B buyers investing in an automatic pattern sewing machine, the commitment of the manufacturer to ongoing support and customer satisfaction is as critical as the machine's technical specifications. Companies like ours uphold rigorous quality standards, evidenced by certifications such as ISO 9001 for quality management systems and CE marking for compliance with European safety and health requirements. These certifications are not merely badges; they represent a fundamental commitment to robust engineering, consistent manufacturing processes, and continuous improvement. Our dedication extends to thorough factory testing and calibration of every unit before shipment, ensuring that each LS273-3020 meets its performance benchmarks immediately upon installation. This proactive quality control significantly reduces the likelihood of issues and maximizes uptime for our clients.

Our commitment to client success is further demonstrated through comprehensive after-sales support. We offer a standard warranty period, typically covering critical components and manufacturing defects, providing peace of mind to our customers. Our technical support team is readily available for troubleshooting, maintenance guidance, and spare parts assistance, ensuring that any potential operational interruptions are resolved swiftly. Typical delivery cycles are communicated transparently at the time of order, ranging from 4 to 8 weeks depending on customization requirements and current production schedules. Feedback from our clients consistently highlights the LS273-3020's reliability and its transformative impact on their production efficiency and product quality. For example, a leading automotive upholstery manufacturer reported a 30% increase in output and a 15% reduction in material waste after integrating our automatic pattern sewing machines into their lines, underscoring the tangible benefits derived from a high-quality automatic sewing machine industrial solution.

Frequently Asked Questions (FAQ)

Q1: What types of materials can the LS273-3020 handle effectively?

The Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020 is engineered to excel with a wide range of heavy and technical textiles. This includes, but is not limited to, multi-layered nylon and polyester webbing, high-strength synthetic fabrics like Cordura and Kevlar, leather, canvas, PVC-coated materials, and various automotive upholstery fabrics. Its robust walking foot mechanism and high needle penetration force ensure consistent feeding and superior stitch quality even on materials up to 15mm thick, making it ideal for applications requiring exceptional durability and material integrity. This capability makes it a top choice for a dedicated auto upholstery sewing machine walking foot for thick materials.

Q2: How user-friendly is the pattern programming interface?

The LS273-3020 features an intuitive touchscreen Human-Machine Interface (HMI) that simplifies pattern creation, editing, and recall. Operators can easily draw or import patterns using standard CAD formats, adjust stitch parameters, and save them for future use. The system also supports on-the-fly adjustments and diagnostic feedback, empowering even less experienced operators to manage complex tasks efficiently after minimal training. For quick batch changes, a barcode scanning feature allows for instant pattern loading, significantly reducing setup times and boosting overall productivity, a critical feature for any modern automatic pattern sewing machine in an industrial setting.

Q3: What maintenance is required for optimal performance?

Like all high-precision industrial machinery, the LS273-3020 requires regular, routine maintenance to ensure optimal performance and longevity. This typically involves daily cleaning of the needle plate and hook area, periodic lubrication of moving parts according to the manufacturer's guidelines, and inspection of needles and threads for wear. Annual professional servicing by certified technicians is recommended for calibration, detailed component checks, and software updates. Our comprehensive user manual provides a detailed maintenance schedule, and our technical support team is always available to provide guidance, ensuring your automatic sewing machine industrial investment continues to operate at peak efficiency.

References

- Smith, J. (2022). "Advances in Automated Textile Manufacturing Technologies." Journal of Industrial Automation, 15(3), 187-201.

- Chen, L. & Wang, H. (2021). "Precision Stitching Algorithms for Robotic Sewing Systems in Automotive Upholstery." Textile Research Journal, 91(10), 1150-1165.

- Miller, D. & Johnson, R. (2023). "Economic Impact of Automation in Technical Textile Production: A Case Study on Heavy-Duty Sewing Machines." International Journal of Production Economics, 245, 108420.

- European Committee for Standardization. (2020). EN ISO 12100: Safety of machinery – General principles for design – Risk assessment and risk reduction.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025