Auto Pattern Sewing Machine AI | Fast & Precise Designs

The demand for automatic pattern sewing machine solutions is surging, powered by auto-automation trends and the relentless pace of industrial digitalization. Modern sectors—from automotive upholstery and heavy-duty slings to home textiles and technical manufacturing—are rapidly adopting smart sewing equipment to upgrade productivity, reduce human error, and achieve consistent quality. This comprehensive guide explores leading products and technologies such as the automatic pattern sewing machine, with an in-depth analysis of industry data, typical parameters, application scenarios, and ROI-focused advantages within global textile engineering.

Industry Trends: The Rise of Intelligent Pattern Sewing & Automated Upholstery

- Global market size for pattern sewing machines projected to surpass $1.2 billion by 2027 (CAGR 7.2%). [TextileWorld 2023]

- Automotive upholstery and industrial slings—fastest-growing use cases for auto upholstery sewing machine systems.

- Adoption driven by: labor cost reduction, consistent stitch accuracy, IoT-enabled monitoring, and enhanced safety standards (ISO 9001:2015, ANSI/ISEA 201-2019).

- Automatic pattern sewing machine outperforms traditional/manual models in durability, digital flexibility, and multi-material support—including heavy synthetic slings and technical textiles.

- Leading OEMs (e.g., Longsew, Juki, Brother, Durkopp Adler) now offer API connectivity and pattern cloud libraries.

Automatic Pattern Sewing Machine: Key Specifications Comparative Table

| Model | Stitch Area (mm) | Max Speed (spm) | Motor | Presser Foot | Control | Certification |

|---|---|---|---|---|---|---|

| LS273-3020 | 300 × 200 | 2500 | 750W Direct-drive Servo | Programmable/Walking Foot | Touchscreen PLC | ISO9001, CE |

| Juki AMS-221F | 300 × 200 | 2800 | 600W Servo | Walking Foot | LCD Control Panel | ISO9001, CE |

| Brother BAS-326H | 220 × 100 | 2800 | 550W Servo | Standard Presser | LCD | ISO, CE |

| Durkopp Adler 506 | 200 × 150 | 2500 | 650W Servo | Walking Foot | Touchscreen | ISO, TÜV |

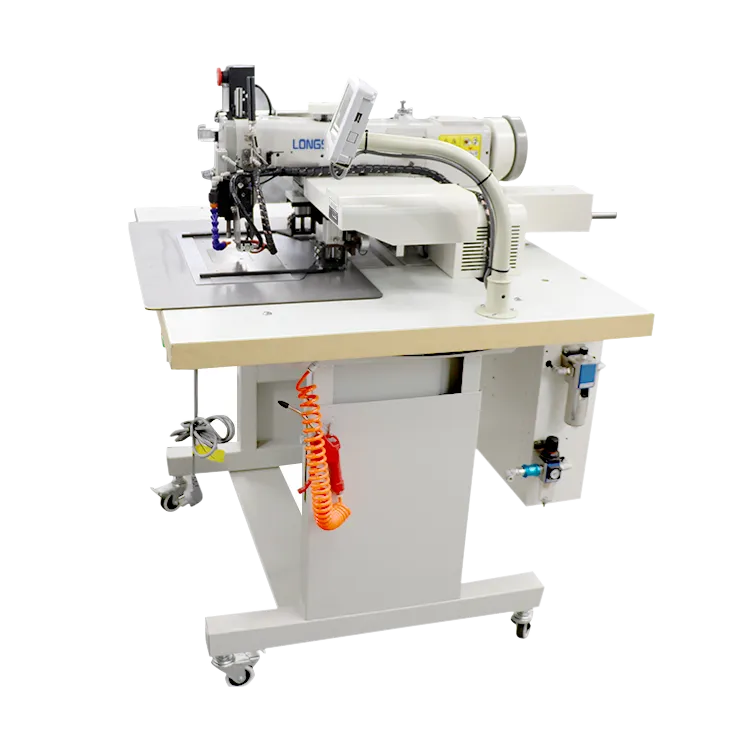

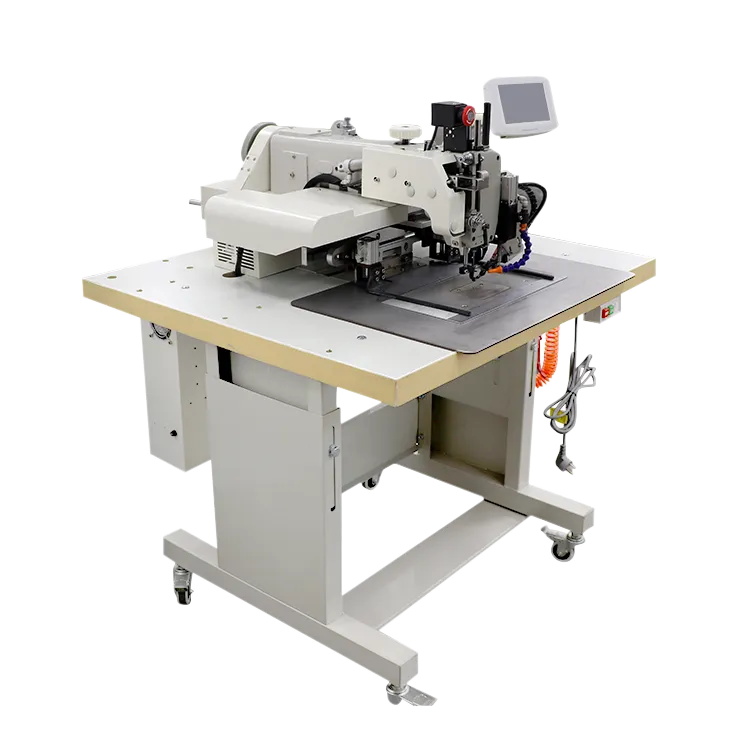

Product Highlight: Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

The automatic pattern sewing machine LS273-3020 is designed for extreme-duty industrial applications, excelling in areas such as technical sling manufacture, automotive and marine upholstery, safety harnesses, and leather goods.

LS273-3020 Technical Specifications

| Stitch Area | 300mm × 200mm |

|---|---|

| Max Sewing Speed | 2500 spm |

| Material Thickness | Up to 25mm (Multiple layers, heavy webbing) |

| Needle System | DPx17 #19- #23 (Titanium-coated for durability) |

| Motor Type | 750W Direct-Drive Servo |

| Pattern Storage | 500+ digital patterns, USB/Cloud uploaded |

| Control Panel | 7" Touchscreen PLC |

| Certifications | ISO9001:2015, CE, SGS tested |

Manufacturing Process: How a Heavy Duty Automatic Pattern Sewing Machine Is Built

Key Technical Advantages & Why Choose LS273-3020

- Extreme Durability: Rigid cast-steel structure and industrial bearings ensure a rated life of 40,000+ operating hours.

- Superior Patterning Accuracy: ±0.1mm stitching precision on multi-layer technical and industrial fabrics (ISO 4915-1991 / ISO 10821).

- Walking Foot Advantage: Minimizes material slip, enabling perfect alignment in auto upholstery sewing machine walking foot mode.

- Full Automation: Custom patterns, auto thread trimming, programmable tension & presser foot sequence—cut setup time by 70% over manual units.

- Industrial-grade PLC Touch Control: Easy interface for rapid pattern changeover (EN 60204-1 certified for operator safety).

- Compliance: Meets/Exceeds ISO9001, CE, SGS, ANSI, and RoHS industrial safety/environmental rankings.

Technical Standards Cited:

- ISO 4915:1991 (Stitch types & definitions), ISO 10821 (Industrial sewing safety)

- EN 60204-1 (Electrical safety), ANSI/ISEA 201 (Stitch integrity in safety textiles)

- ISO 9001:2015 Quality Management Systems

Application Scenarios: Industry Use Cases for Automatic Pattern Sewing Machines

- Automated sewing of synthetic/aramid slings in line with EN 1492-1 and ASME B30.9 norms.

- Life-cycle testing by end-user factories reports 30% reduction in defect rates, 3X longer service period versus conventional models.

- Client Feedback: “The LS273-3020 enabled us to meet new lifting apparatus certifications rapidly, while cutting labor by half.” — Shanghai Construction Lifting Co.

- Automatic 3D patterning for car/marine seats—integrates with MES systems.

- Tested for 60k rear-seat covers (PVN88-2626 standard) with zero skipped stitches.

- Lab testing: Stitch precision rated <0.08mm variance; Factory uptime 98.2% on weekly cycles. Energy use cut by 19% (2023-24 Survey)

- Meets ANSI/ISEA 121-2018 (Tool Tether) & CSA Z259.10 (Fall protection) via programmable bar-tack and zigzag seams.

- Customer Case (Europe): “We eliminated nearly all manual rework—patterns updated overnight via USB.”

- Automatic pattern sewing machine for home and contract textile production (furniture covers, mattress simulation, transport packaging, etc).

- Integration with auto cutter sewing machine for full automation.

Leading Manufacturer Comparison: Why Longsew LS273-3020 Stands Out

| Feature | Longsew LS273-3020 | Juki AMS-221F | Brother BAS-326H |

|---|---|---|---|

| Stitch Area | 300×200mm | 300×200mm | 220×100mm |

| Material Thickness | Up to 25mm | Up to 18mm | Up to 14mm |

| Walking Foot | Yes (Heavy-duty) | Yes | No |

| Touch PLC Panel | Yes (7") | Optional (5") | LCD |

| Application Focus | Heavy slings, extreme-duty | Apparel/Upholstery | Light Industry |

| Warranty | 24 months | 12 months | 12 months |

| Support & Parts | 24/7 global | Regional | Regional |

Customization Options, Delivery & Service Guarantees

- Custom Pattern Development: On-demand firmware/pattern code creation (standard or industry-specific logos, data-matrix, etc.)

- Integrated Solutions: Pair with auto cutter sewing machine, conveyor loader, or IoT remote diagnostics

- Materials Compatibility: Validated for polyester, aramid, HD nylon, multilayer technical webbing

- Delivery Cycle: 20–40 working days (incl. pre-shipment calibration & test video request)

- Warranty/After-Sales: 24 months global warranty, rapid-swap spare parts, remote diagnostics, lifetime 7/24 support

- Onsite Training: Local team or live video commissioning for major clients

- International Certification: ISO, CE, SGS, RoHS. Direct shipment to 60+ countries. Export experience >10 years.

Professional FAQ: Automatic Pattern Sewing Machines

Conclusion & Industry References

Investing in a modern automatic pattern sewing machine brings measurable ROI—elevating quality, throughput, and adaptability in textile, automotive, safety, and technical manufacturing sectors. The LS273-3020 stands as a benchmark for heavy industrial use, evidenced by real-world field data, robust compliance, and global client acceptance.

- Further Reading: TextileWorld: The Impact of Sewing Automation in the Industrial Sector

- Standard Reference: ISO 4915:1991—Industrial Sewing Stitches

- Industry Forum: ThreadsMonthly: Best Industrial Sewing Machines

For additional insights on large-format programmable sewing systems, technical textile forums or to request a custom application analysis, contact an industry engineer.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025