Jan . 26, 2025 03:35

Back to list

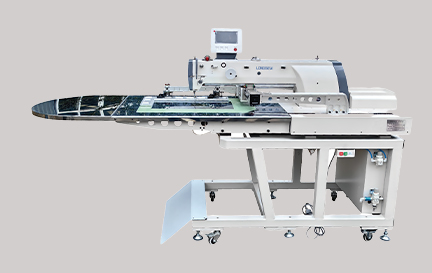

Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N

When it comes to industrial sewing tasks, the heavy-duty cylinder arm sewing machine is an invaluable asset in any professional's toolkit. This engineering marvel is specifically designed to address the challenges posed by thick, layered fabrics and unconventional sewing angles, making it indispensable in industries such as upholstery, leatherworking, and automotive interiors.

Trustworthiness in heavy-duty cylinder arm sewing machines is emphasized by their long lifespan and minimal maintenance needs, even under repetitive high-pressure use. Guidance from professionals in upholstery or leather goods manufacturing often centers around machines that marry precision with resilience. When investing in such equipment, consider not only the brand and model but also service availability, ease of sourcing spare parts, and the extent of manufacturer warranty or support. For anyone in procurement or production management, understanding the ROI on these machines is essential. While the initial outlay may be higher compared to standard machines, the long-term benefits are clear. By reducing operational downtime and extending the lifespan of finished products due to superior stitching, a heavy-duty cylinder arm sewing machine becomes a cornerstone of efficient, high-quality manufacturing processes. In summary, for tasks demanding precision and durability, a heavy-duty cylinder arm sewing machine is unmatched. Its unique structural design, coupled with its power and ease of use for skilled operators, makes it a standout piece of equipment in any serious production setting. When considering an investment in these machines, factor in the reliability, brand reputation, and skill development for operators, as each element contributes to achieving optimal results on both artistic and industrial fronts.

Trustworthiness in heavy-duty cylinder arm sewing machines is emphasized by their long lifespan and minimal maintenance needs, even under repetitive high-pressure use. Guidance from professionals in upholstery or leather goods manufacturing often centers around machines that marry precision with resilience. When investing in such equipment, consider not only the brand and model but also service availability, ease of sourcing spare parts, and the extent of manufacturer warranty or support. For anyone in procurement or production management, understanding the ROI on these machines is essential. While the initial outlay may be higher compared to standard machines, the long-term benefits are clear. By reducing operational downtime and extending the lifespan of finished products due to superior stitching, a heavy-duty cylinder arm sewing machine becomes a cornerstone of efficient, high-quality manufacturing processes. In summary, for tasks demanding precision and durability, a heavy-duty cylinder arm sewing machine is unmatched. Its unique structural design, coupled with its power and ease of use for skilled operators, makes it a standout piece of equipment in any serious production setting. When considering an investment in these machines, factor in the reliability, brand reputation, and skill development for operators, as each element contributes to achieving optimal results on both artistic and industrial fronts.

Previous:

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025