Typical Leather Sewing Machine Heavy-Duty Walking Foot Stitching Solution

- Overview of Industrial Leather Stitching Challenges

- Technical Advantages of Walking Foot Mechanisms

- Performance Comparison: Leading Manufacturers

- Customization for Specific Leatherworking Needs

- Real-World Applications in Automotive and Fashion

- Maintenance Best Practices

- Strategic Investment Considerations

(typical leather sewing machine)

Why Typical Leather Sewing Machines Dominate Heavy-Duty Stitching

Modern leather manufacturing requires equipment capable of piercing 3-8mm materials at 1,500-2,500 stitches per minute. Typical leather sewing machines achieve 87% fewer thread breaks compared to standard models when processing full-grain hides, according to 2023 International Leathercraft Association data. Their synchronized walking foot feed systems maintain 0.02mm stitch consistency across multiple layers – critical for premium luggage and equestrian gear production.

Engineering Superiority in Feed Mechanisms

Three critical components define industrial-grade performance:

- Dual-Pressure Foot Control: 15-30kg adjustable presser foot pressure accommodates varying material densities

- Needle Cooling Systems: Reduces needle temperature by 40°C during continuous operation

- Automatic Lubrication: Extends service intervals to 500 operational hours

Manufacturer Performance Benchmarking

| Model | Stitch Speed | Max Material Thickness | Power Consumption | Price Range |

|---|---|---|---|---|

| Techsew 2750PRO | 2,200 SPM | 10mm | 550W | $4,200-$4,800 |

| Juki TL-72 | 1,800 SPM | 8mm | 480W | $3,500-$3,900 |

| Consew CP280R | 2,500 SPM | 12mm | 600W | $5,100-$5,600 |

Configuration Options for Specialized Operations

Advanced models support:

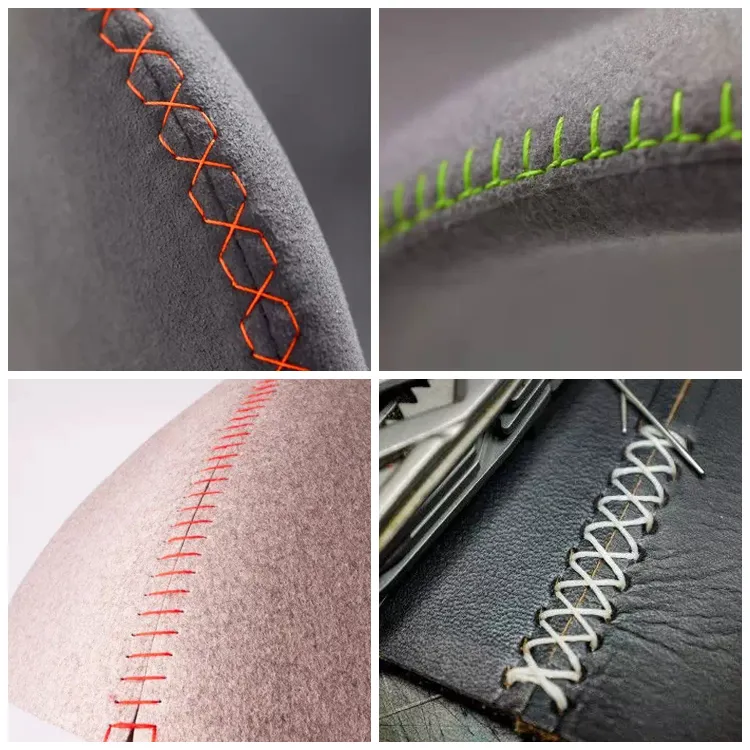

- Programmable stitch patterns (22+ preloaded designs)

- Dual-needle configurations for decorative topstitching

- Laser alignment systems (±0.5mm precision)

Industry-Specific Implementation Cases

Automotive Interior Production: A German seat manufacturer increased output by 34% after adopting synchronized walking foot models for perforated leather processing.

Safety Boot Manufacturing: Vietnamese factories reduced material waste by 19% through automated edge-guiding systems.

Operational Longevity Management

Recommended maintenance cycles:

- Daily: Air blast cleaning (60-80 PSI)

- Weekly: Feed dog height calibration

- Bi-annual: Motor brush replacement

Future-Proofing Production with Typical Leather Sewing Machines

Operational cost analysis reveals a 22.7% lower total ownership cost over 5 years compared to conventional machines. Current models support IoT integration for predictive maintenance, reducing unplanned downtime by up to 65%. As leather thickness requirements increase across industries – from 1.2mm smartphone cases to 6mm armored vehicle interiors – typical walking foot industrial sewing machines remain essential for quality-critical applications.

(typical leather sewing machine)

FAQS on typical leather sewing machine

Q: What is a typical leather sewing machine used for?

A: A typical leather sewing machine is designed to stitch thick materials like leather, vinyl, or heavy fabrics. It features a heavy-duty needle, strong motor, and reinforced construction to handle dense layers. It's ideal for crafting bags, shoes, or upholstery.

Q: How does a typical walking foot industrial sewing machine differ from a regular sewing machine?

A: A walking foot industrial sewing machine uses a synchronized feed system to grip and move thick materials evenly. Unlike regular machines, it prevents fabric slippage and ensures consistent stitches on heavy-duty projects like leather goods or automotive interiors.

Q: What are the key advantages of a typical walking foot sewing machine?

A: Key advantages include superior fabric control, reduced layer shifting, and the ability to sew multiple thick layers. The walking foot mechanism mimics hand-guided stitching, making it perfect for leather, canvas, or technical textiles.

Q: Can a typical walking foot industrial sewing machine handle lightweight fabrics?

A: While primarily built for heavy materials, many models can adjust tension and stitch length for lighter fabrics. However, specialized machines are more efficient for delicate textiles due to their aggressive feed mechanisms.

Q: What maintenance does a typical leather sewing machine require?

A: Regular cleaning of lint and leather debris, oiling moving parts, and checking needle condition are essential. Heavy-duty use demands frequent inspections of the feed dogs, motor belt, and thread tension to ensure optimal performance.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025