Cylinder Bed Sewing Machine

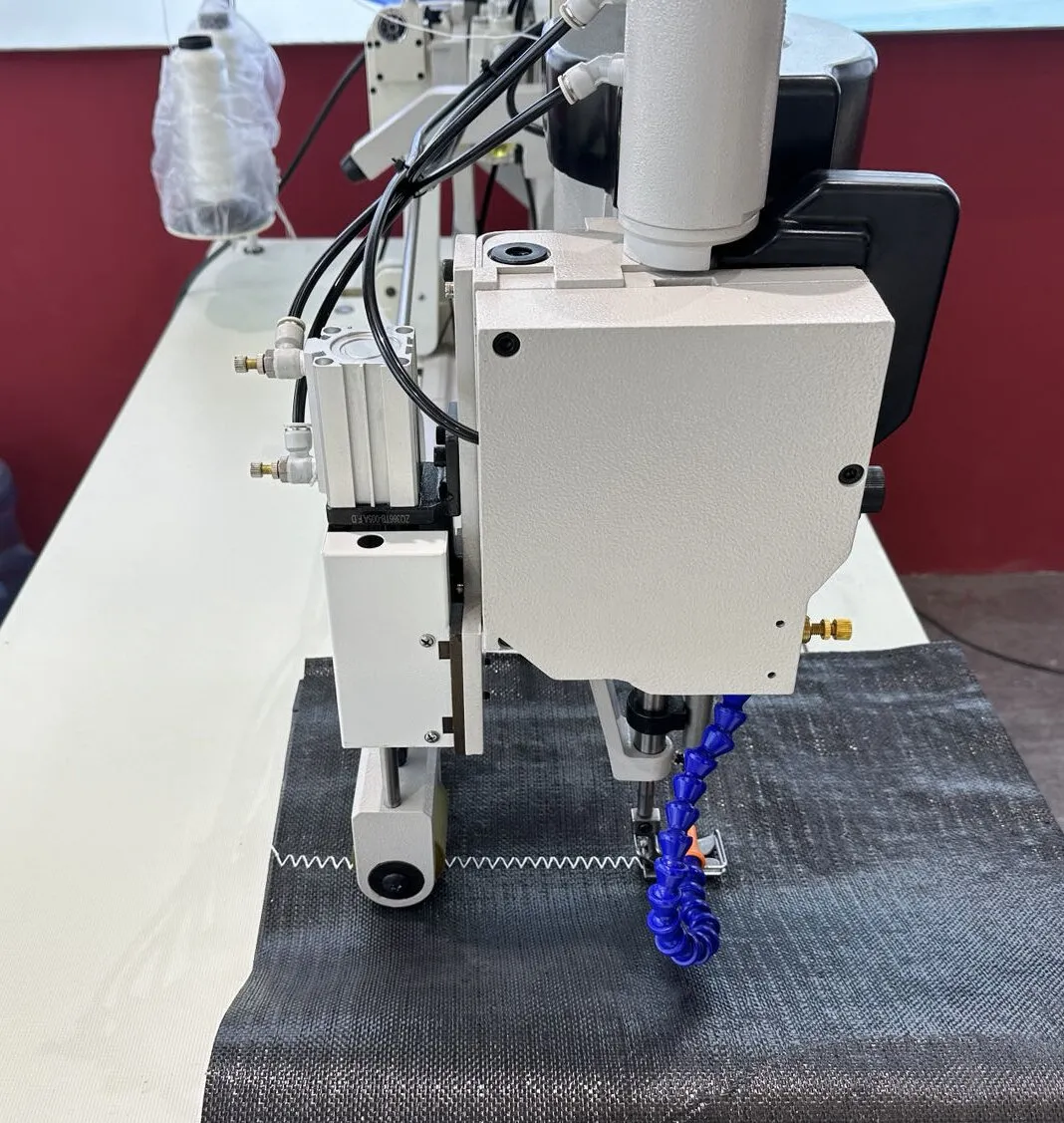

A cylinder bed sewing machine is a specialized industrial sewing machine designed for stitching cylindrical and curved surfaces. Unlike flatbed sewing machines, which work best on flat materials, a cylinder bed sewing machine features a raised, cylindrical sewing platform that allows for greater flexibility when sewing round or irregularly shaped items such as bags, gloves, hats, and footwear.

One of the primary advantages of a cylinder bed sewing machine is its ability to reach difficult areas that traditional flatbed machines cannot handle. The raised cylinder design allows fabric to move freely around the curved surface, making it perfect for industries such as leather goods manufacturing, automotive upholstery, and shoe production.

Modern cylinder bed sewing machines come equipped with advanced features such as servo motors for energy efficiency, automatic thread trimming, and programmable stitch settings for enhanced precision. Additionally, some models offer walking foot technology, which ensures even feeding of thick and layered materials.

Whether you are in the fashion industry, leatherworking, or industrial textile production, investing in a cylinder bed sewing machine can greatly improve your ability to handle complex stitching tasks with accuracy and efficiency.

Cylinder Bed Leather Sewing Machine: The Perfect Tool for Leather Craftsmanship

For professionals working with leather, a cylinder bed leather sewing machine is an indispensable tool. Leather is a tough and thick material that requires a powerful machine capable of producing strong, even stitches. A cylinder bed leather sewing machine is specifically designed to handle leather goods such as handbags, belts, saddles, and high-end shoes.

One of the standout features of a cylinder bed leather sewing machine is its powerful motor and heavy-duty needle system. These machines typically come with a walking foot mechanism, ensuring that thick layers of leather are fed evenly through the sewing area without slipping. This prevents inconsistent stitching and ensures durability.

Additionally, many cylinder bed leather sewing machines feature adjustable presser foot pressure, allowing users to accommodate different thicknesses of leather. Some models also offer automatic backstitching functions, reinforcing stitches for added strength.

Precision is crucial when working with leather, and a high-quality cylinder bed leather sewing machine provides the control needed to create professional-grade products. Whether you're a leather artisan, manufacturer, or repair specialist, investing in the right machine will improve efficiency and product quality.

Cylinder Arm Sewing Machine: A Versatile Solution for Professional Sewing

A cylinder arm sewing machine, also known as a cylinder bed sewing machine, is a specialized machine designed for sewing three-dimensional objects. The extended arm of this machine allows for greater maneuverability, making it an excellent choice for industries that require high-precision stitching on items like bags, gloves, shoes, and upholstery.

The cylinder arm sewing machine is particularly valuable in leatherworking, where thick and rigid materials require specialized handling. With features like walking foot mechanisms, needle feed systems, and servo motor technology, these machines ensure smooth and even stitching, even on difficult materials.

Some of the key benefits of a cylinder arm sewing machine include:

Improved access to tight spaces: The extended arm allows for stitching in areas that are difficult to reach with a flatbed machine.

Stronger stitch quality: Many models include reinforced stitching options for added durability.

Versatility: These machines can handle a wide range of materials, including leather, canvas, vinyl, and heavy-duty fabrics.

For manufacturers of luxury leather goods, outdoor gear, and automotive upholstery, a cylinder arm sewing machine is a critical investment that enhances product quality and production efficiency.

Choosing the Right Cylinder Bed Sewing Machine for Your Needs

When selecting a cylinder bed sewing machine, cylinder bed leather sewing machine, or cylinder arm sewing machine, there are several key factors to consider.

The first and most important consideration is material compatibility. If you work with thick materials like leather, canvas, or vinyl, you need a machine with a powerful motor and reinforced stitch capabilities. A cylinder bed leather sewing machine is ideal for these applications.

Another crucial factor is stitching speed and precision. High-speed models improve productivity, while machines with adjustable speed settings provide better control for intricate designs. Features such as servo motors, programmable stitch patterns, and automatic thread trimming can further enhance efficiency.

Machine durability is another key consideration. Industrial sewing requires machines that can withstand continuous operation, so choosing a model with a strong metal frame, high-quality components, and easy maintenance options will ensure long-term performance.

Lastly, consider ergonomics and ease of use. A cylinder arm sewing machine with an adjustable work surface, simple threading systems, and digital controls will be more user-friendly, reducing operator fatigue and improving workflow.

Investing in the right machine ensures superior stitching quality, increased efficiency, and long-lasting durability, making it a valuable asset for businesses in leatherworking, bag manufacturing, and industrial sewing.

Heavy Duty Cylinder Bed Sewing FAQs

What is the main difference between a cylinder bed sewing machine and a flatbed sewing machine?

A cylinder bed sewing machine has a raised, cylindrical work surface, allowing for easier stitching of curved and tubular objects such as bags, gloves, and shoes. In contrast, a flatbed sewing machine is designed for sewing flat materials, making it less suitable for three-dimensional projects.

Why should I choose a cylinder bed leather sewing machine for leatherwork?

A cylinder bed leather sewing machine is specifically designed to handle thick and tough materials like leather. It provides strong, even stitching and includes features such as a walking foot, adjustable presser foot pressure, and heavy-duty needles to ensure professional-quality leather products.

Can a cylinder arm sewing machine be used for all types of fabrics?

Yes, a cylinder arm sewing machine is versatile enough to handle a variety of materials, including leather, canvas, vinyl, and heavy fabrics. However, it is primarily designed for thick and curved materials, making it ideal for industries such as leather goods, upholstery, and bag manufacturing.

What features should I look for in a high-quality cylinder bed sewing machine?

Key features to look for in a cylinder bed sewing machine include a powerful motor, a walking foot mechanism, automatic thread trimming, adjustable stitch length, and a durable metal construction. For leatherwork, reinforced needle systems and presser foot adjustments are essential for smooth and even stitching.

Is a cylinder bed sewing machine worth the investment for small businesses?

Absolutely. A cylinder bed sewing machine increases efficiency, enhances product quality, and allows for more versatile stitching options. For small businesses specializing in leather goods, bags, or upholstery, the investment pays off in improved production capabilities and professional-grade stitching results.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025