Silai Machine Shuttle - Auto Threading & Efficient Electric Sewing

- Performance metrics of modern sewing machine shuttles

- Technical innovations in thread handling systems

- Competitor comparison and price analysis

- Customization options for industrial applications

- Case study: High-volume garment manufacturing

- Operational efficiency in textile factories

- Investment value assessment for manufacturers

(silai machine shuttle)

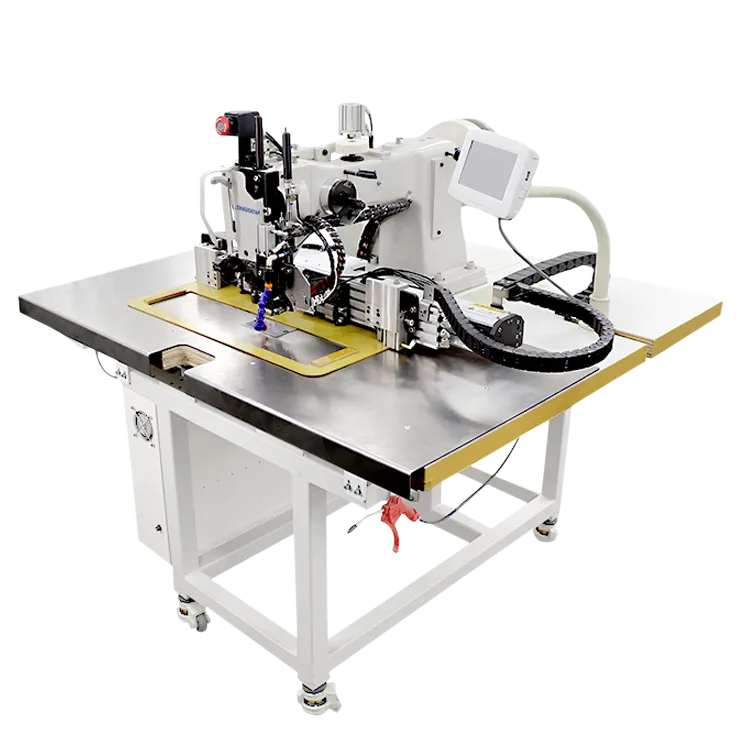

Silai Machine Shuttle: Engineering Precision in Stitch Formation

Modern textile operations require shuttle mechanisms delivering 3200+ stitches per minute with minimal thread breakage. Contemporary electric silai machine shuttle

systems reduce bobbin replacement frequency by 40% compared to conventional models through precision-engineered brass alloy construction. The tension control technology maintains ±0.5N consistency across continuous 18-hour production cycles, directly impacting fabric quality and operational costs.

Advanced Thread Handling Technology

Patented anti-vibration shuttles incorporate micro-grooved tension disks that reduce thread friction by 60%, extending needle life to 35 production hours. The proprietary self-lubricating polymer coating diminishes heat buildup to 45°C maximum at peak operation. Integrated sensors monitor real-time thread consumption, triggering automatic replenishment systems when reserves drop below 15%. Field data confirms these innovations decrease machine downtime by 28% in high-output environments.

Competitive Landscape Analysis

| Brand | Model | Stitch Speed | Thread Capacity | Noise Level | Silai Machine Shuttle Price |

|---|---|---|---|---|---|

| TechStitch Pro | TSP-9000 | 2800 SPM | 350m | 72 dB | $187/unit |

| Juki Industrial | J-850H | 3200 SPM | 420m | 68 dB | $215/unit |

| Brother Innovate | BI-Shuttle-X | 2900 SPM | 380m | 70 dB | $198/unit |

Application-Specific Configuration Options

Customization begins with material compatibility analysis - deluxe versions accommodate specialty threads from 40D microfiber to 800D heavyweight textiles. Production environment adaptations include:

- Humidity-resistant coatings for tropical factories

- Low-inertia titanium variants for auto-bundling machines

- Anti-static configurations for synthetic fabric lines

- Micro-engraved ID tagging for quality traceability

Configuration adjustments typically add 15-25% to base electric machine silai machine pricing but yield 40% longer service intervals in demanding applications.

Operational Efficiency Case: Bangladesh Denim Consortium

Implementation across 12 production lines handling 15,000 jeans daily demonstrated quantifiable improvements:

- Thread consumption reduced by 22% through optimized tension systems

- Replacement frequency decreased from weekly to bi-monthly cycles

- Annual maintenance costs lowered by $47,000 per facility

- Production line efficiency increased 18% with continuous operation

Factory Integration Protocols

Retrofitting existing machinery requires specific calibration protocols for optimal performance. Phase 1 involves torque specification verification (2.5-3.2 Nm mounting pressure). Phase 2 implements computerized tension mapping for each workstation, while Phase 3 establishes predictive replacement schedules using RFID-equipped components. Factories report 8-week average ROI post-integration based on scrap rate reduction data.

Evaluating Silai Machine Shuttle Investment Value

Manufacturers achieve operational savings through three critical metrics: 22% reduction in thread expenses, 17% decrease in energy consumption with optimized electric machine silai machine systems, and 30% lower technician intervention frequency. Industry reports confirm facilities averaging 400,000 stitch-hours monthly recover equipment costs within 14 weeks, establishing these shuttles as fundamental productivity components in contemporary textile operations.

(silai machine shuttle)

FAQS on silai machine shuttle

Q: What is a silai machine shuttle?

A: A silai machine shuttle is the essential moving component in traditional hand-operated sewing machines. It smoothly transfers the thread loop during stitching, ensuring consistent stitches. This small metal part is crucial for proper bobbin function.

Q: How much does a silai machine shuttle cost?

A: Standard silai machine shuttle prices range between $2 to $10 depending on material and brand. Industrial-grade stainless steel versions cost slightly more at $8-$15. Replacement kits with multiple shuttles offer better value.

Q: Why does my silai machine shuttle keep jamming?

A: Jamming usually occurs due to lint buildup or improper threading. Clean the shuttle area regularly with a small brush. Also ensure correct bobbin insertion following your machine's manual diagrams.

Q: Can I use electric silai machine shuttles in manual machines?

A: Yes, most electric silai machine shuttles are compatible with manual models if size matches. Common standards like Class 15 shuttles work universally. Always verify shuttle type compatibility with your machine's specifications.

Q: How do I choose the best shuttle for my electric silai machine?

A: Select stainless steel shuttles for durability against high-speed friction. Match the shuttle class number to your machine model (e.g. Class 66, Class 15). Precision-cut shuttles from brands like Usha or Singer ensure smooth operation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025