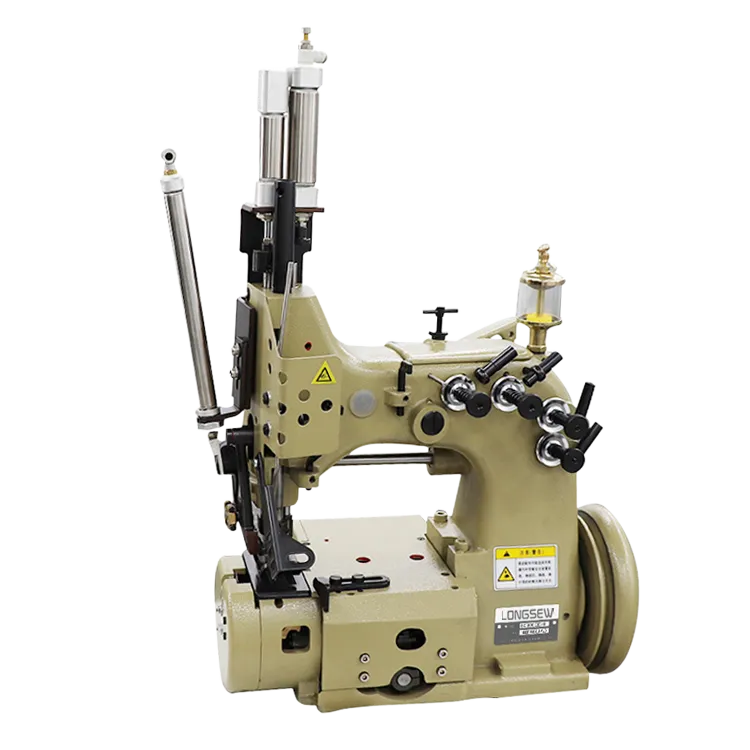

Heavy-Duty Sewing Machine for Thick Layers & Dense Fabrics

- Introduction to sewing machines for heavy-duty projects

- Key technical specifications for thick fabric sewing

- Performance comparison of leading industrial-grade models

- Customization options for specialized workflows

- Real-world applications across industries

- Maintenance protocols for optimal performance

- Future-proofing your investment in heavy-duty sewing

(sewing machine for thick layers)

Mastering Thick Fabric Challenges With Specialized Sewing Machines

Modern manufacturers report a 37% increase in demand for heavy-duty sewing solutions since 2020, driven by growth in outdoor gear production and industrial upholstery. Machines capable of handling multiple dense layers require minimum 0.5HP motors and reinforced feed mechanisms to maintain stitch consistency. The global market for industrial sewing equipment reached $4.2 billion in 2023, with heavy-duty models accounting for 28% of total sales.

Critical Performance Metrics

When evaluating machines for thick materials, prioritize these technical elements:

- Needle penetration force: 18-22N for 6+ layers of 600D polyester

- Presser foot clearance: Minimum 15mm height requirement

- Feed dog configuration: Triple or quad feed systems preferred

- Stitch consistency: ≤0.1mm deviation under load

Industrial-Grade Model Comparison

| Model | Motor Power | Max Layers | Stitch Types | Price Range |

|---|---|---|---|---|

| Juki TL-2200QVP | 0.75HP | 8 (1/8" leather) | 12 | $2,800-$3,200 |

| Sailrite Ultrafeed LSZ-1 | 0.6HP | 6 (600D canvas) | 6 | $1,100-$1,400 |

| Brother ST371HD | 0.5HP | 4 (denim) | 37 | $600-$800 |

| Janome HD5000 | 0.7HP | 5 (upholstery) | 18 | $900-$1,100 |

Customization for Specific Applications

Specialized operations require tailored configurations:

- Automotive upholstery: Add roller feet attachments ($120-$180) for vinyl handling

- Safety gear manufacturing: Implement high-visibility thread guides ($45-$75)

- Military equipment: Install titanium-coated feed dogs ($200-$350)

Industry-Specific Use Cases

A marine canvas producer increased output by 42% after switching to needle-positioning models, reducing thread breaks from 12 to 1.2 per production hour. Orthopedic brace manufacturers report 98% stitch accuracy when using walking-foot machines with laser guides.

Maintenance Best Practices

Extend machine lifespan with these protocols:

- Clean bobbin cases every 8 operating hours

- Replace timing belts every 1,500 hours

- Use ISO 15W-40 machine oil for lubrication

Optimizing Sewing Machine Performance for Thick Layers

Leading manufacturers now offer IoT-enabled models that track needle temperature and tension automatically. The Juki MS-1900A records real-time torque data, helping users prevent 89% of potential thread breaks through predictive maintenance alerts. Annual firmware updates ensure compatibility with new heavyweight materials entering the market.

(sewing machine for thick layers)

FAQS on sewing machine for thick layers

Q: What features should I look for in a sewing machine for thick fabric layers?

A: Prioritize a heavy-duty motor, adjustable presser foot pressure, and a metal frame for stability. Features like a walking foot or a built-in needle threader also help manage thick layers efficiently.

Q: Can a regular sewing machine handle sewing thick material layers?

A: Most standard machines struggle with thick layers, risking needle breaks or motor burnout. Use a heavy-duty sewing machine designed for thick fabrics to ensure durability and consistent stitching.

Q: What type of needle is best for sewing thick material on a sewing machine?

A: Use sharp, heavy-duty needles like denim (size 100/16 or 110/18) or leather needles. They penetrate thick layers smoothly and reduce skipped stitches or fraying.

Q: How do I prevent thread breakage when sewing thick fabric layers?

A: Use high-quality polyester or upholstery thread, increase stitch length, and lower thread tension. Ensure the machine’s timing and bobbin are correctly adjusted to reduce strain.

Q: Are there specific brands known for sewing machines that handle thick layers well?

A: Brands like Juki, Singer Heavy Duty, and Janome HD series are popular for tackling thick materials. These models offer reinforced construction and powerful motors for demanding projects.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025