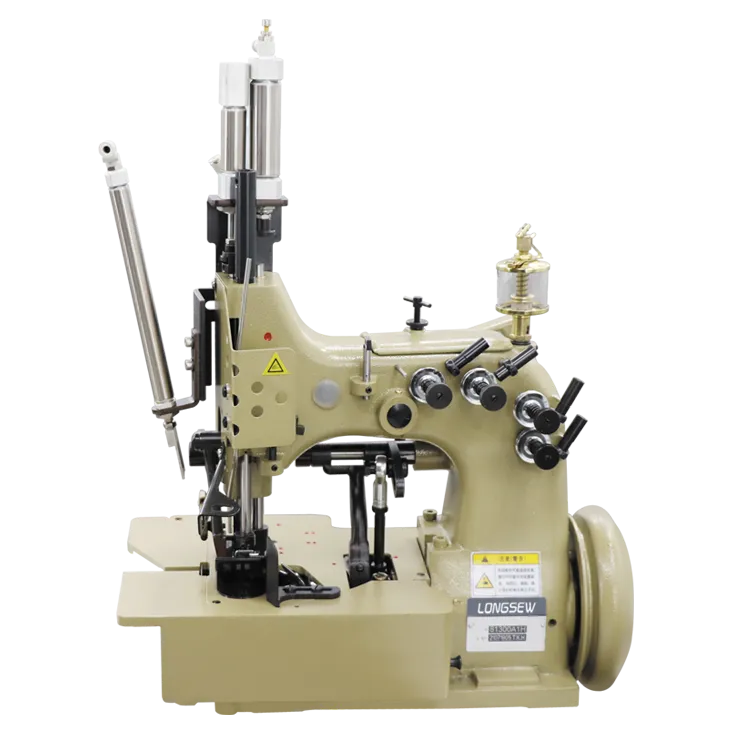

double stitch machine

Understanding the Double Stitch Machine A Comprehensive Overview

In the ever-evolving world of textile manufacturing, efficiency and precision are paramount. Among the various sewing technologies that have emerged, the double stitch machine stands out for its unique capabilities and significant advantages in specific applications. This article delves into the features, functions, and benefits of double stitch machines while examining their impact on the textile industry.

What is a Double Stitch Machine?

A double stitch machine, as its name implies, is designed to create two parallel lines of stitching simultaneously. This innovative sewing technology typically utilizes two needles and two threads, which allows it to produce a strong, decorative, and consistent seam. These machines are often employed in both industrial and domestic sewing applications, providing users with a reliable means to craft durable products.

Working Mechanism

The working mechanism of a double stitch machine is relatively straightforward. By using two spools of thread simultaneously, the machine can create two rows of stitches across the fabric. The needles work in tandem, penetrating the fabric at the same time but producing two distinct lines of stitching. The threading typically involves a looper or a secondary threading system that interlocks the two rows, ensuring stability and strength.

These machines are available in various configurations, with some capable of accommodating different types of stitches, such as straight, zigzag, or decorative stitches. Advanced models also include programmable functions that allow users to customize stitch patterns for enhanced creativity in their projects.

Advantages of Double Stitch Machines

1. Enhanced Durability Double stitching inherently provides greater strength compared to single-stitched seams. This is particularly advantageous in high-stress areas, such as the seams on denim jeans or heavy jackets, where durability is critical.

2. Efficiency in Production The ability to simultaneously sew two lines of stitching allows for faster production times, which can lead to increased efficiency in manufacturing settings. This is a significant advantage in commercial operations seeking to meet high-volume demands.

3. Improved Appearance Double stitching adds an aesthetic appeal to garments and products. The two lines of stitching can serve as a decorative element, enhancing the overall design without requiring extra sewing steps.

double stitch machine

4. Versatility Double stitch machines can handle a range of fabrics, from lightweight materials to heavier textiles. This versatility makes them suitable for various applications, including fashion design, upholstery, and industrial work.

5. Cost-Effectiveness While the initial investment in a double stitch machine may be higher than that of standard sewing machines, the long-term savings from increased durability and reduced production time can offset these costs.

Applications in the Textile Industry

Double stitch machines are prevalent in several sectors within the textile industry

- Apparel Manufacturing Fashion brands utilize double stitch machines for producing garments that require durability and style, including casual wear and outerwear.

- Upholstery In the furniture industry, double stitching is often employed for creating strong seams on upholstered items, ensuring longevity and resistance to wear and tear.

- Automotive Textiles The automotive industry leverages double stitching for seat covers and interior components, where strength and safety are key concerns.

- Outdoor Gear Outdoor equipment, such as tents and backpacks, often benefits from the robust stitching that double stitch machines provide.

Conclusion

The double stitch machine exemplifies the intersection of functionality and innovation in the textile industry. With its ability to enhance durability, improve production efficiency, and add a decorative touch, it has become an invaluable tool for manufacturers and designers alike. As the demand for high-quality, long-lasting textiles continues to rise, the importance of such advanced sewing technology cannot be overstated. With ongoing advancements in machine design and technology, double stitch machines will likely play an ever-increasing role in shaping the future of textile manufacturing.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025