Heavy-Duty vs Industrial Sewing Machines: Suitability For Light Fabrics

Heavy-Duty vs Industrial Sewing Machines: Suitability For Light Fabrics

Difference Between Heavy-Duty And Industrial Sewing Machines

Intended Purpose

Heavy-Duty Sewing Machines: These machines are made for home workers who sometimes need to work with tougher fabrics like leather or denim. Even though they can handle more complex jobs than a regular home machine, they are not made for high-volume, continuous sewing.

Industrial Sewing Machines: These tools are made for use in businesses. They are made to run for a long time, often several hours a day, and move a lot of stuff. They are usually found where many things are made, like clothing plants, upholstery shops, and other large-scale production settings.

Construction and Durability

Heavy-Duty Sewing Machines: These machines are generally more durable than home machines. They often have a metal frame and parts. Some parts may still be made of plastic, though. They are made to last, but not necessarily for continuous, long-term use.

Industrial Sewing Machines: These machines are mostly made of high-quality metals and are made to last. They can withstand wear and tear and are made to last for many years under intensive usage.

Performance and Speed

Heavy Duty Sewing Machines: They’re faster than regular machines but not as quick as industrial ones. They can work with rigid materials but might need breaks so they don’t overheat.

Industrial Sewing Machines: These are the top performers. They stitch fast, much faster than heavy-duty machines, and can keep going without getting too hot.

Size and Portability

Heavy-Duty Sewing Machines: While sturdier and sometimes heavier than regular domestic machines, these machines are still designed with home use in mind. They are relatively compact and can be moved if needed.

Industrial Sewing Machines: These are large, often fixed to tables, and are not meant to be moved frequently. They require a dedicated space, and their setup indicates a permanent or semi-permanent sewing station.

Maintenance

Heavy-Duty Sewing Machines: Maintenance routines for these machines are more frequent than industrial ones but less intensive. Regular cleaning, occasional oiling, and timely servicing should suffice.

Industrial Sewing Machines: Given their continuous operation, these machines demand regular and thorough maintenance. However, due to their robust build, they might require less frequent repairs if appropriately maintained.

Price Point

Heavy-Duty Sewing Machines: While priced higher than standard domestic machines, they are considerably more affordable than industrial machines. They strike a balance between enhanced capabilities and cost.

Industrial Sewing Machines: The initial investment in these machines is high. Their specialized construction, durability, and high-performance capabilities come at a premium.

User-Friendliness

Heavy-Duty Sewing Machines: These machines, designed for domestic use, often have user-friendly features. They might have digital displays, easy threading capabilities, and straightforward stitch selection processes.

Industrial Sewing Machines: Due to their specialized nature, there might be a steeper learning curve associated with industrial machines. They are often designed with professionals in mind, prioritizing efficiency and precision over user-friendly features.

Accessories and Parts Availability

Heavy-Duty Sewing Machines: Since these machines cater to domestic users, their accessories and replacement parts are relatively easy to find. Many sewing stores and online platforms offer components compatible with popular heavy-duty machine models.

Industrial Sewing Machines: Parts and accessories for these machines might not be as readily available in standard stores. Users often source them from specialized suppliers or directly from manufacturers.

Workspace Requirements

Heavy-Duty Sewing Machines: A sturdy table in a home setting is usually sufficient for these machines.

Industrial Sewing Machines: These machines often come with tables or workstations, requiring a dedicated space with ample room for operation and material handling.

Heavy-duty and industrial sewing machines each cater to their unique set of requirements. While industrial machines are designed for specialized, high-volume work, heavy-duty machines sit in a versatile middle ground. They are robust enough to handle rigid materials, but are they adaptable to lighter fabrics?

Can Heavy-Duty Sewing Machines Handle Light Fabric?

Studies and opinions from professionals in the field reinforce the idea that heavy duty sewing machines, with the right settings and techniques, can indeed sew light fabrics. Manufacturers also cater to this need by incorporating versatile features in many of their heavy-duty models.

Adjustability for Light Fabrics

Stitch Length and Width Adjustment:

A shorter stitch length for lighter fabrics can provide a more delicate seam that blends well with the fabric’s natural drape. Conversely, a longer stitch suits heavier materials, providing stronger holds. Adjusting stitch width is particularly crucial when creating decorative stitches or buttonholes. By tailoring these settings, one can achieve a professional finish, reducing skipped stitches or fabric bunching risks.

Tension Control:

Improper tension can lead to issues like loose stitches or thread bunching on the fabric’s underside. A balanced, slightly lower tension is often ideal for lightweight fabrics to prevent puckering. Conversely, thicker fabrics might require increased tension for a secure stitch. An intuitive tension control system can ensure that users can swiftly fine-tune this balance, accommodating a spectrum of fabric types.

Presser Foot Pressure:

The presser foot holds the fabric against the machine’s feed dogs, assisting in its smooth movement as stitches are formed. The pressure exerted by the presser foot needs modification depending on the fabric’s thickness. Light fabrics require gentle pressure to avoid stretching or distortion, while robust fabrics might necessitate firmer pressure for efficient feed. Machines that allow for presser foot pressure adjustments allow users to customize this crucial point of fabric-machine interaction, ensuring optimal fabric feed and reduced sewing mishaps.

Needle Choices:

Heavy-duty machines often provide a range of needle choices. For light fabrics, slender needles like sizes 60/8 or 70/10 are appropriate, causing minimal puncture damage. Thicker fabrics, however, require heftier needles that can pierce through without bending or breaking. Moreover, specialized needles, such as ballpoint for knits or sharps for silks, further optimize the sewing process, tailoring the needle’s design to the fabric’s unique characteristics.

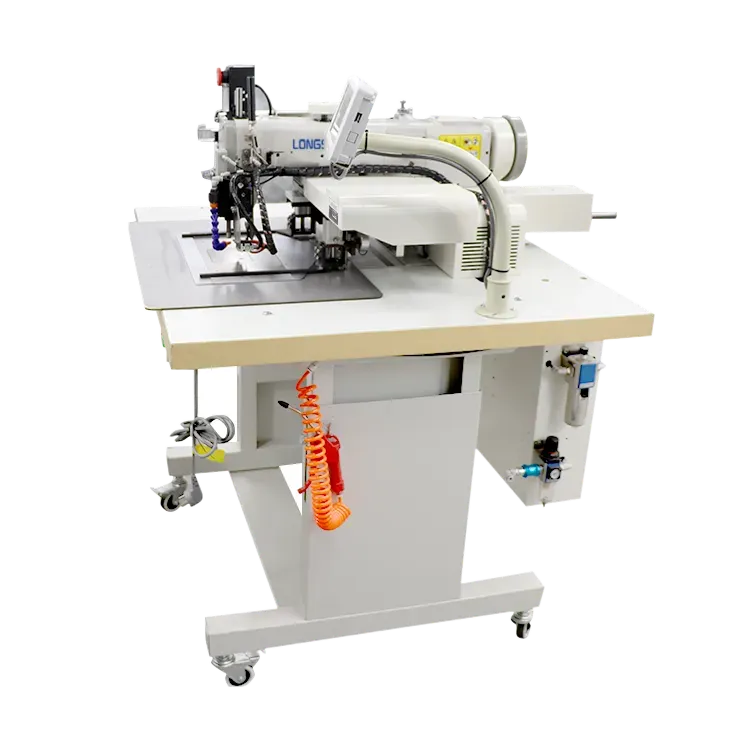

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

Techniques and Accessories for Sewing Light Fabrics

With their delicate nature and fluid drape, light fabrics can be challenging to work with. They might slip, pucker, or get caught in the machine, leading to less-than-desirable results. However, sewing light fabrics can be a delightful experience with the right techniques and accessories.

- Using Stabilizers

Stabilizers form a foundation for delicate fabrics, ensuring they retain their shape during the sewing process. Different types of stabilizers cater to varied needs. Tear-away stabilizers are used for projects where you can remove the stabilizer after sewing, while cut-away stabilizers remain in place, offering lasting support. Wash-away stabilizers dissolve after coming in contact with water, which is excellent for temporary application on fabrics where no trace of stabilizer should remain. Using stabilizers can transform the handling properties of light fabrics, making them more akin to medium-weight fabrics, thereby simplifying the sewing process.

- Proper Fabric Handling

Delicate fabrics often have a mind of their own, sliding or shifting during sewing. Fabric weights and pins become essential tools in this scenario. Weights can hold larger fabric pieces in place when cutting or sewing, ensuring accuracy. Pins, on the other hand, can anchor fabrics together, especially at seams or hems. Magnetic seam guides can also be positioned on the machine’s throat plate to guide fabric straight. Another tip is to handle the fabric gently, ensuring there’s no unnecessary pulling or tugging, which can distort its natural lay.

- Test Swatches

Before diving into the main project, testing on swatches is always beneficial. This allows sewers to familiarize themselves with the fabric’s behavior and helps determine the ideal tension, stitch length, and width. Testing ensures you avoid mistakes on the final piece, saving time and resources. It’s a proactive step that boosts confidence and ensures a high-quality final product.

- Specialized Feet:

Presser feet act as the main point of contact between the machine and the fabric. For light fabrics, specialized feet can make a world of difference. A walking foot, for instance, ensures even fabric feed from both top and bottom, reducing puckering. A Teflon or roller foot can prevent fabrics like silk or satin from getting stuck. A narrow straight stitch foot can offer more precision when sewing straight seams on delicate fabrics.

Possible Concerns and Solutions When Sewing Light Fabrics

Feed Dogs and Fabric Feed

Feed dogs are the teeth-like mechanisms on a sewing machine’s needle plate that help guide the fabric through as you sew. When dealing with light fabrics, there’s a potential risk of these feed dogs snagging or pulling the material, leading to damage or misalignment. Light fabrics, being delicate, may get caught in larger feed dogs intended for heavy materials.

Solution: Some heavy-duty sewing machines come with adjustable feed dogs or the ability to lower them, allowing for smoother feeding of light fabrics. For machines that don’t have this feature, using a cover plate or a specialized presser foot can help create a barrier between the fabric and the aggressive feed dogs, ensuring the material glides smoothly. Another practical tip is placing a tear-away or wash-away stabilizer beneath the light fabric, giving it additional structure and support as it passes over the feed dogs.

Machine Speed Control

Heavy-duty machines equipped with powerful motors can operate at very high speeds. While this is beneficial for quickly sewing rigid materials, it can be detrimental when working with delicate fabrics. Too much speed can lead to skipped stitches, fabric distortion, or even tears.

Solution: Many modern sewing machines come with adjustable speed settings. When working with light fabrics, reducing the speed is advised, giving the sewer more control over the fabric’s movement and stitch placement. This adjustment is especially crucial when navigating intricate patterns or corners.

Thread Choice Considerations

The thread is an often-overlooked component in the sewing process. However, it is crucial, especially when dealing with light fabrics. Heavy-duty machines are designed to handle thicker threads used for robust materials, but using such threads on delicate fabrics can result in puckering or even tearing.

Solution: Matching the thread type and weight to the fabric used is essential. Opt for finer threads that can pass through the material without causing strain for light fabrics. Threads like cotton, silk, or fine polyester are ideal choices. Additionally, ensure the machine’s tension settings are adjusted to accommodate the chosen thread and fabric combination.

Machine Maintenance

The performance of a sewing machine, regardless of its build or intended use, greatly depends on its maintenance. When sewing light fabrics, even minor hiccups caused by a lack of maintenance can lead to significant issues, from uneven stitches to fabric damage.

Solution: Regularly clean the machine, ensuring the area around the needle and feed dogs is free from lint, dust, or fabric remnants. As per the manufacturer’s instructions, oiling the machine will also ensure that its parts move smoothly. It’s also advisable to periodically check for worn-out components, like needles, and replace them promptly. Using a sharp needle for light fabrics can significantly affect the sewing outcome.

Conclusion

Heavy-duty and industrial sewing machines serve distinct needs, with the former bridging the gap between household and professional machines. While industrial units excel in continuous, specialized tasks, heavy-duty machines can effectively sew light fabrics when tailored with appropriate settings, such as stitch length, tension control, and needle choices. However, challenges like machine speed, feed dogs, and thread choice need careful management. Regular maintenance and choosing versatile machines, backed by expert advice and reviews, can ensure optimum results across various fabrics, from robust denim to delicate silks.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

Hebei LongSew Machinery Technology Co. Ltd is beginning as sewing machine parts supplier, now Longsew have over twenty years experience in complete set sewing machine offering.

- Home

- Products

- About us

- Applications

- Popularity Products

- News

- Contact

- featuredproducts

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

Warning: Undefined array key "alt" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1096/footer.php on line 28

-

No.368 North Youyi Street, Shijiazhuang City, Hebei Province, China

-

-