Gen . 21, 2025 05:28

Back to list

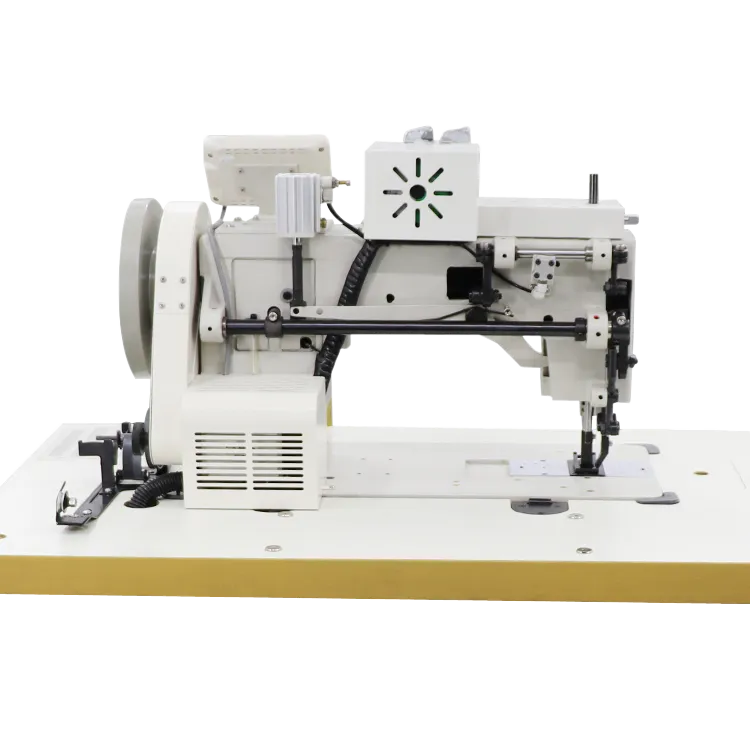

Jumbo Bag / Big Bag Automatic Computerized Pattern Sewing Machine For Bulk Bag Loopsew LS200-3040/LS200-3050

In the rapidly changing landscape of textile manufacturing, the CNC programmable sewing machine has emerged as a transformative tool, revolutionizing how garments and other fabric products are made. Combining the precision of CNC (Computer Numerical Control) technology with advanced sewing capabilities, these machines are at the forefront of an industry poised for innovation.

Trustworthiness in the use of CNC programmable sewing machines is established through a foundation of robust design, durability, and consistent performance. Leading manufacturers provide detailed documentation, customer support, and continuous updates to both hardware and software, ensuring users can rely on their machines for high-volume, precision sewing operations. Case studies from credible sources illustrate how manufacturers using these machines have seen substantial improvements in product quality, customer satisfaction, and operational resilience. Product innovation is further fueled by the customization possibilities these machines offer. Fashion designers and manufacturers alike can experiment with a plethora of designs and pattern complexities that were previously unachievable with traditional sewing machinery. The ability to swiftly transition from design conceptualization to production accelerates the time-to-market for new clothing lines, an invaluable advantage in the fast-paced fashion industry. In conclusion, the CNC programmable sewing machine is not just a piece of equipment but a key enabler of progress within the textile industry. Its adoption promises not only to increase operational efficiency and reduce costs but also to propel innovation in fabric design and production. As expertise in these machines grows and integration with digital systems becomes more sophisticated, the industry can expect sustained enhancements in productivity, quality, and environmental sustainability. For manufacturers, embracing this technology represents a strategic investment in the future of textile production, opening pathways to greater market share and profitability.

Trustworthiness in the use of CNC programmable sewing machines is established through a foundation of robust design, durability, and consistent performance. Leading manufacturers provide detailed documentation, customer support, and continuous updates to both hardware and software, ensuring users can rely on their machines for high-volume, precision sewing operations. Case studies from credible sources illustrate how manufacturers using these machines have seen substantial improvements in product quality, customer satisfaction, and operational resilience. Product innovation is further fueled by the customization possibilities these machines offer. Fashion designers and manufacturers alike can experiment with a plethora of designs and pattern complexities that were previously unachievable with traditional sewing machinery. The ability to swiftly transition from design conceptualization to production accelerates the time-to-market for new clothing lines, an invaluable advantage in the fast-paced fashion industry. In conclusion, the CNC programmable sewing machine is not just a piece of equipment but a key enabler of progress within the textile industry. Its adoption promises not only to increase operational efficiency and reduce costs but also to propel innovation in fabric design and production. As expertise in these machines grows and integration with digital systems becomes more sophisticated, the industry can expect sustained enhancements in productivity, quality, and environmental sustainability. For manufacturers, embracing this technology represents a strategic investment in the future of textile production, opening pathways to greater market share and profitability.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025