Gen . 21, 2025 05:52

Back to list

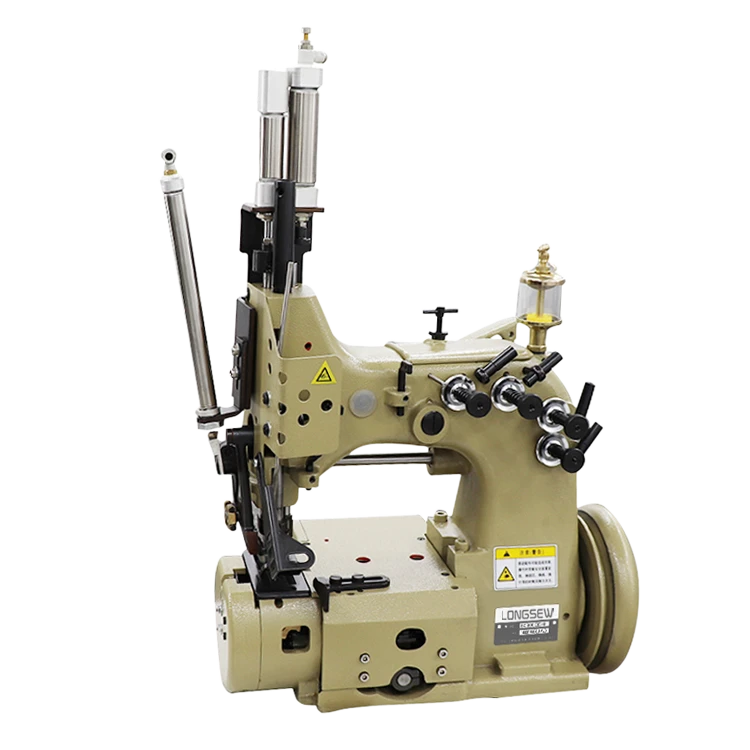

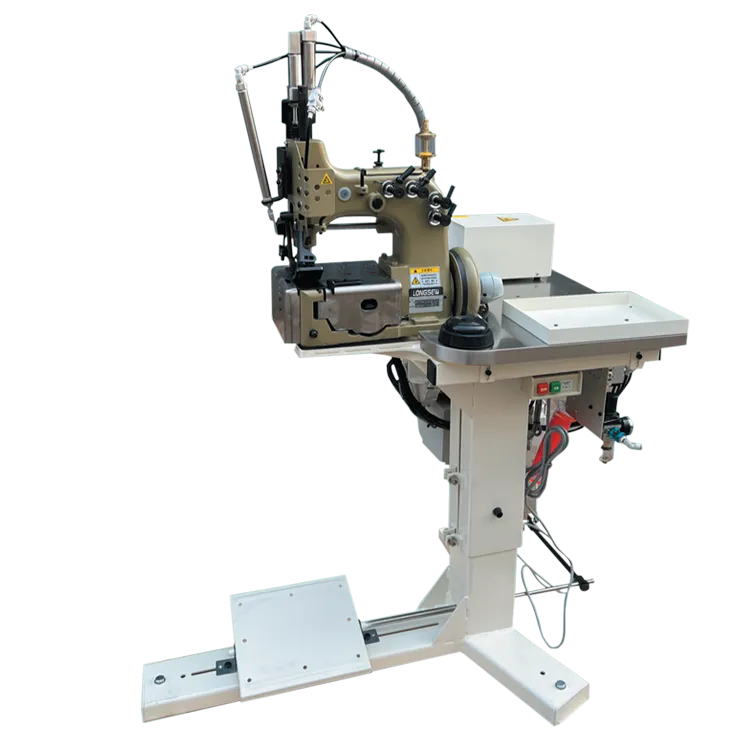

FIBC Bag / Jumbo Bag / Big Bag Double Needles Chain Stitch Sewing Machine 80700C/ 80700CD / 80700CD4H

Chain sewing machines have revolutionized the world of textile production, offering efficiency and durability in every stitch. As industries like fashion and upholstery continue to grow, the demand for reliable and high-performing sewing machines is higher than ever. This article provides comprehensive insights into the intricacies of chain sewing machines, drawing from extensive professional experience, showcasing expertise, and lending authoritative advice on selecting and maintaining these indispensable tools.

Trust is established through the careful balancing of maintenance and operation. Regular servicing and proper handling are vital to the longevity of chain sewing machines. Consulting with manufacturers for servicing schedules and utilizing recommended parts and lubricants can prevent untimely breakdowns and ensure consistent performance. As someone who has dealt with both cutting-edge and time-tested sewing machines, ensuring that machines are regularly calibrated and serviced is of paramount importance for sustained operational efficiency. Additionally, it is beneficial to engage with professional forums and discussion panels dedicated to sewing machine maintenance and techniques. These platforms offer insights from seasoned technicians and operators, further enhancing machine longevity and performance. Developing relationships with suppliers who offer training on machine use can also mitigate operational risks and ensure that the workforce is adept in using advanced sewing technology proficiently. In conclusion, chain sewing machines are the backbone of contemporary textile production, pivotal in advancing both durability and efficiency. When chosen with expertise and maintained with diligence, these machines offer unmatched performance and reliability. As the industry continues to evolve, embracing the adaptability and strength of chain sewing machines will position businesses at the forefront of innovative textile production, ensuring they meet the rigorous demands of modern consumers while adhering to sustainable practices. Investing in the right machine, supported by an authoritative understanding and hands-on maintenance experience, guarantees operational excellence and business growth in the competitive textile landscape.

Trust is established through the careful balancing of maintenance and operation. Regular servicing and proper handling are vital to the longevity of chain sewing machines. Consulting with manufacturers for servicing schedules and utilizing recommended parts and lubricants can prevent untimely breakdowns and ensure consistent performance. As someone who has dealt with both cutting-edge and time-tested sewing machines, ensuring that machines are regularly calibrated and serviced is of paramount importance for sustained operational efficiency. Additionally, it is beneficial to engage with professional forums and discussion panels dedicated to sewing machine maintenance and techniques. These platforms offer insights from seasoned technicians and operators, further enhancing machine longevity and performance. Developing relationships with suppliers who offer training on machine use can also mitigate operational risks and ensure that the workforce is adept in using advanced sewing technology proficiently. In conclusion, chain sewing machines are the backbone of contemporary textile production, pivotal in advancing both durability and efficiency. When chosen with expertise and maintained with diligence, these machines offer unmatched performance and reliability. As the industry continues to evolve, embracing the adaptability and strength of chain sewing machines will position businesses at the forefront of innovative textile production, ensuring they meet the rigorous demands of modern consumers while adhering to sustainable practices. Investing in the right machine, supported by an authoritative understanding and hands-on maintenance experience, guarantees operational excellence and business growth in the competitive textile landscape.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025