Innovative Machines for Automated Fabric Cutting and Stitching Solutions

The Evolution of Automatic Cutting and Sewing Machines

In the modern textile and garment industry, the efficiency and precision of manufacturing are paramount. One of the technological advancements that have revolutionized this sector is the automatic cutting and sewing machine. These machines have not only streamlined production processes but have also significantly enhanced product quality, allowing manufacturers to meet the ever-increasing demands of the global market.

Historical Context

The journey of automatic cutting and sewing machines began in the late 19th century, with the invention of the sewing machine itself. Early models were manually operated and required skilled labor for operation. While they were groundbreaking at the time, they still posed limitations in terms of speed and consistency. As the industrial revolution progressed, manufacturers sought innovations that would automate these processes, leading to the development of the first automatic machines.

Advancements in Technology

Today's automatic cutting and sewing machines incorporate sophisticated technologies such as computer-aided design (CAD), computer numerical control (CNC), and artificial intelligence (AI). These machines are capable of executing complex tasks with minimal human intervention. For cutting, high-precision lasers and blades can now be programmed to cut fabric in intricate patterns with an accuracy that far exceeds traditional methods. This not only reduces fabric waste but also speeds up production times considerably.

In the sewing process, advanced sewing machines equipped with multi-head systems can handle multiple layers of fabric simultaneously, increasing output without sacrificing quality. Furthermore, features such as automatic thread trimming, tension adjustment, and motif recognition allow for greater flexibility and creativity in design.

Benefits to the Industry

The introduction of automatic cutting and sewing machines has brought numerous benefits to the garment industry. First and foremost, they enhance productivity. With machines operating at a faster pace than human workers, companies can produce larger volumes in shorter timeframes. This efficiency is especially crucial in a fast fashion environment where trends can shift rapidly.

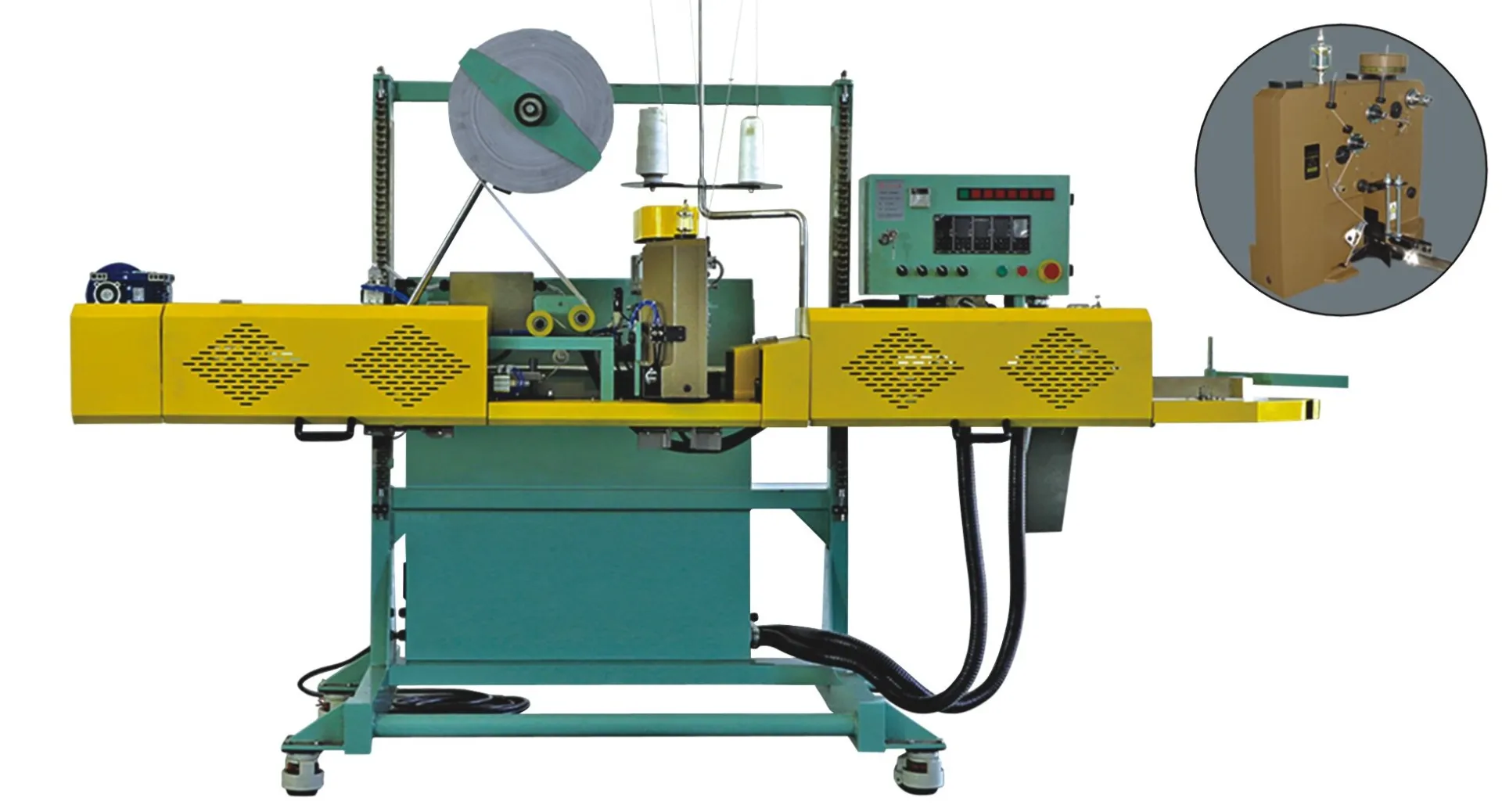

automatic cutting and sewing machine

Moreover, these machines improve accuracy. By reducing human error, manufacturers can ensure consistent quality across all products. This standardization helps in building brand reputation and consumer trust, essential elements in a competitive marketplace. Additionally, the precision of cutting machines minimizes fabric wastage, leading to cost savings and a reduction in the environmental impact of textile production.

Challenges Faced

Despite their advantages, the integration of automatic cutting and sewing machines is not without challenges. The initial investment in such technology can be substantial, making it difficult for small and medium-sized enterprises to adopt these machines. Additionally, there is a risk of job displacement, as automation can lead to a reduced need for manual labor. This necessitates a careful balance between embracing technology and fostering a skilled workforce capable of managing and maintaining these advanced machines.

Future Outlook

Looking forward, the future of automatic cutting and sewing machines appears promising. As technology continues to evolve, we can expect even greater advancements in automation. The integration of AI and machine learning could lead to machines capable of learning from past production runs, optimizing processes in real-time and further enhancing efficiency.

Additionally, with the growing emphasis on sustainability, manufacturers are likely to invest more in eco-friendly practices supported by automated technologies. Innovations might focus on recycling materials and reducing energy consumption, aligning production methods with global sustainability goals.

Conclusion

In conclusion, automatic cutting and sewing machines have significantly transformed the textile and garment industry. By enhancing productivity and accuracy, these machines are helping manufacturers meet the demands of a dynamic market. While challenges remain, the ongoing evolution of technology suggests a bright future for automation in the industry. As we continue to innovate, the potential for developing machines that are even more efficient and environmentally friendly will undoubtedly reshape the landscape of textile manufacturing for years to come.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025