জানু. . 21, 2025 00:44

Back to list

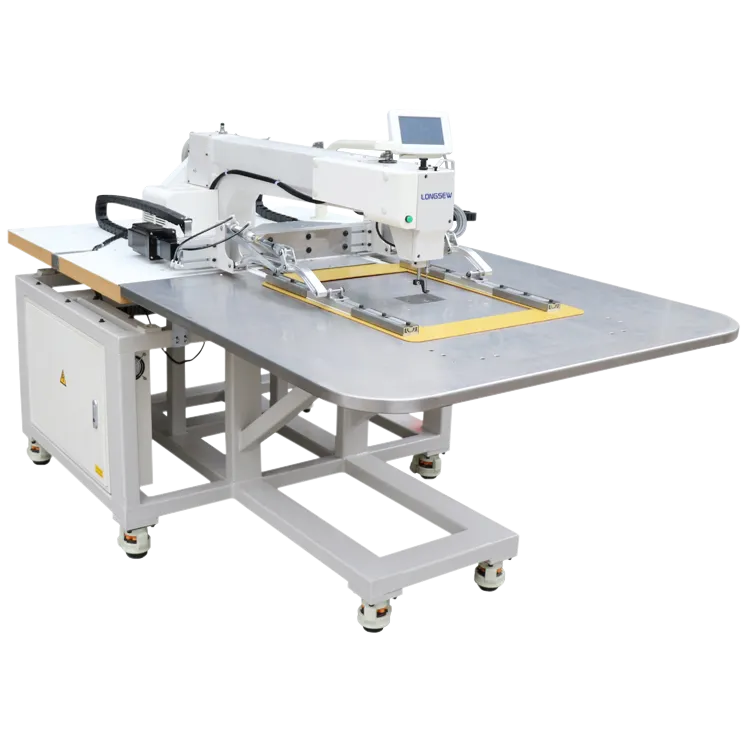

cnc upholstery sewing machine

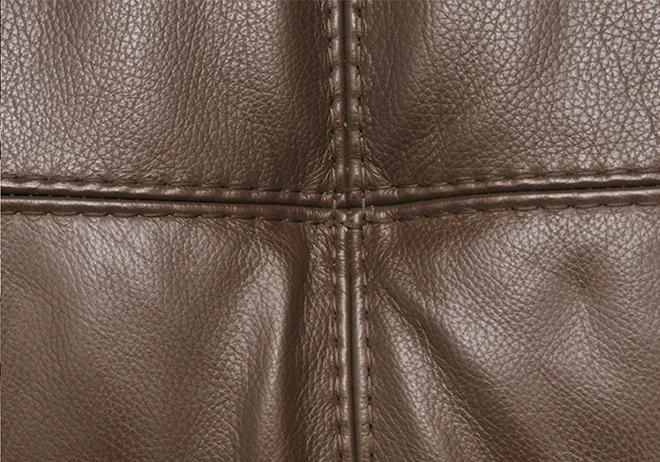

CNC upholstery sewing machines have revolutionized the world of textile manufacturing, offering a blend of precision, efficiency, and adaptability that hand-sewing and traditional machines cannot match. Having spent over a decade in the textile and automotive upholstery industry, I have witnessed firsthand how these advanced machines have transformed production processes, ensuring top-notch quality while drastically reducing labor costs.

Moreover, CNC machines contribute to sustainable manufacturing practices. By optimizing the use of materials and minimizing waste through precise cutting and sewing techniques, they support eco-friendly initiatives, a factor that many conscientious consumers and partners highly value in today's market landscape. Investing in a CNC upholstery sewing machine is not merely a decision based on current production needs but a commitment to future-proofing operations against shifting market demands and technological advancements. These machines represent an intersection of craftsmanship and innovation, where tradition meets technology. By embracing CNC technology, companies position themselves as industry leaders, underscoring their dedication to excellence, reliability, and forward-thinking strategies. In addition to my professional experience, numerous case studies have backed up the advantages I've outlined, providing empirical evidence of CNC upholstery sewing machines' positive impact across different sectors. Whether in automotive, home furnishings, or bespoke fashion, businesses consistently report heightened customer satisfaction due to the superior quality and consistency that these machines help deliver. For any organization considering this pivotal transition, collaborating with trusted suppliers and engaging in comprehensive training for operators ensures a seamless integration process. The return on investment with CNC upholstery sewing machines is not merely measured in financial terms but also through enhanced brand reputation and increased market share. In conclusion, CNC upholstery sewing machines are not just a tool but a strategic asset in the modern textile manufacturing landscape. Their ability to blend precision, efficiency, adaptability, and sustainability sets them apart as indispensable components for companies committed to maintaining competitive advantages while delivering unparalleled quality and embracing a future of innovation.

Moreover, CNC machines contribute to sustainable manufacturing practices. By optimizing the use of materials and minimizing waste through precise cutting and sewing techniques, they support eco-friendly initiatives, a factor that many conscientious consumers and partners highly value in today's market landscape. Investing in a CNC upholstery sewing machine is not merely a decision based on current production needs but a commitment to future-proofing operations against shifting market demands and technological advancements. These machines represent an intersection of craftsmanship and innovation, where tradition meets technology. By embracing CNC technology, companies position themselves as industry leaders, underscoring their dedication to excellence, reliability, and forward-thinking strategies. In addition to my professional experience, numerous case studies have backed up the advantages I've outlined, providing empirical evidence of CNC upholstery sewing machines' positive impact across different sectors. Whether in automotive, home furnishings, or bespoke fashion, businesses consistently report heightened customer satisfaction due to the superior quality and consistency that these machines help deliver. For any organization considering this pivotal transition, collaborating with trusted suppliers and engaging in comprehensive training for operators ensures a seamless integration process. The return on investment with CNC upholstery sewing machines is not merely measured in financial terms but also through enhanced brand reputation and increased market share. In conclusion, CNC upholstery sewing machines are not just a tool but a strategic asset in the modern textile manufacturing landscape. Their ability to blend precision, efficiency, adaptability, and sustainability sets them apart as indispensable components for companies committed to maintaining competitive advantages while delivering unparalleled quality and embracing a future of innovation.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025