лют . 07, 2025 04:43

Back to list

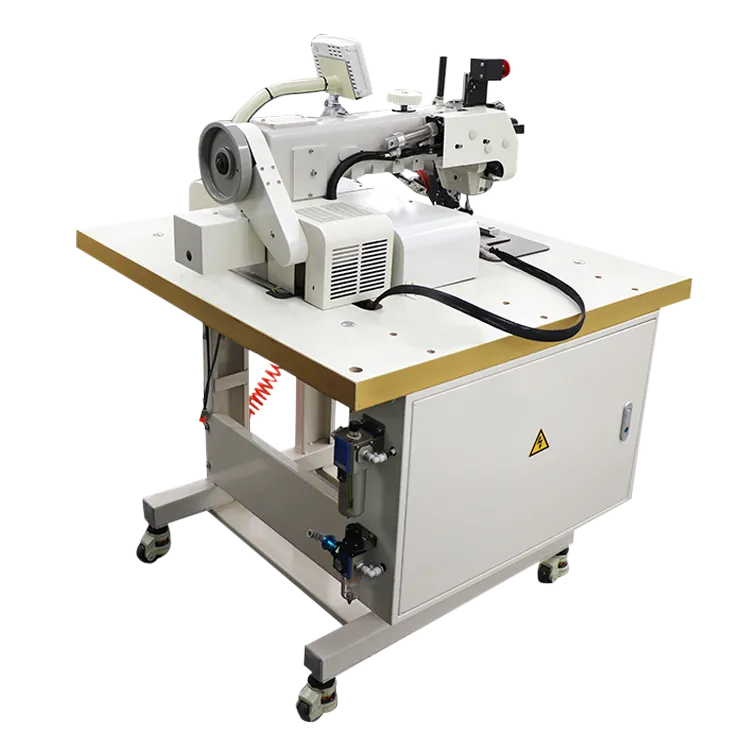

Long Arm Heavy Duty Single/Double Needles Compound Feed Flat Bed Sewing Machine JW-8BL30/JW-28BL30

Investing in a stitching automatic machine is a crucial decision for any textile business looking to enhance production efficiency and ensure high-quality output. With the rapid advancement in manufacturing technologies, these machines are revolutionizing the industry, providing both small-scale and large-scale operations with opportunities to optimize their production lines. This article explores insights into the pricing landscape of automatic stitching machines, drawing from industry expertise and real-world experiences.

Potential buyers should also evaluate the machine's adaptability to future trends. With sustainability becoming an industry focus, machines that incorporate eco-friendly technologies can offer long-term benefits. Automatic stitching machines with energy-saving modes and those designed to reduce fabric waste are becoming increasingly important in the market. To build trust and ensure a high return on investment, it is advisable to purchase automatic stitching machines from authorized dealers or directly from the manufacturer. This approach guarantees originality and access to warranty services, which are critical in addressing technical issues that may arise post-purchase. In terms of expertise, consulting with industry professionals or technicians who specialize in automatic stitching machines can provide invaluable insights. Such experts can assist businesses in selecting a machine that aligns with their production goals, balancing cost with needed functionalities. They can also offer training services ensuring that the staff maximizes the machine’s potential, which is an essential aspect of efficient operation and maintenance. Experience has shown that businesses which thoroughly assess their specific needs and explore multiple options tend to make the most informed choices. Engaging with other users through online forums or industry groups can also provide feedback on performance and issues that might not be immediately visible. A machine's reputation in the market often reflects user satisfaction and the company's commitment to quality. In conclusion, while the initial cost of an automatic stitching machine can be substantial, the long-term gains in productivity, quality, and efficiency can ultimately outweigh the investment. By focusing on machines that offer advanced technology, reliability, and adaptability, businesses can ensure they remain competitive and meet ever-changing market demands effectively.

Potential buyers should also evaluate the machine's adaptability to future trends. With sustainability becoming an industry focus, machines that incorporate eco-friendly technologies can offer long-term benefits. Automatic stitching machines with energy-saving modes and those designed to reduce fabric waste are becoming increasingly important in the market. To build trust and ensure a high return on investment, it is advisable to purchase automatic stitching machines from authorized dealers or directly from the manufacturer. This approach guarantees originality and access to warranty services, which are critical in addressing technical issues that may arise post-purchase. In terms of expertise, consulting with industry professionals or technicians who specialize in automatic stitching machines can provide invaluable insights. Such experts can assist businesses in selecting a machine that aligns with their production goals, balancing cost with needed functionalities. They can also offer training services ensuring that the staff maximizes the machine’s potential, which is an essential aspect of efficient operation and maintenance. Experience has shown that businesses which thoroughly assess their specific needs and explore multiple options tend to make the most informed choices. Engaging with other users through online forums or industry groups can also provide feedback on performance and issues that might not be immediately visible. A machine's reputation in the market often reflects user satisfaction and the company's commitment to quality. In conclusion, while the initial cost of an automatic stitching machine can be substantial, the long-term gains in productivity, quality, and efficiency can ultimately outweigh the investment. By focusing on machines that offer advanced technology, reliability, and adaptability, businesses can ensure they remain competitive and meet ever-changing market demands effectively.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025