Sewing Thick Canvas Made Easy Heavy-Duty Machines & Expert Tips

- Understanding the challenges of sewing thick canvas

- Technical specifications for heavy-duty sewing machines

- Performance comparison: Top 5 industrial machines

- Custom needle and thread configurations

- Workflow optimization for canvas projects

- Real-world applications across industries

- Long-term value of proper equipment selection

(sewing thick canvas)

Mastering the Art of Sewing Thick Canvas

Working with heavy canvas (18-24 oz/sq yd) requires specialized techniques and equipment. Over 68% of leatherworkers transitioning to canvas report premature machine failures due to improper tool selection. Industrial-grade machines capable of handling dense materials must deliver ≥15mm stitch length and maintain 2,500-3,000 stitches per minute under load.

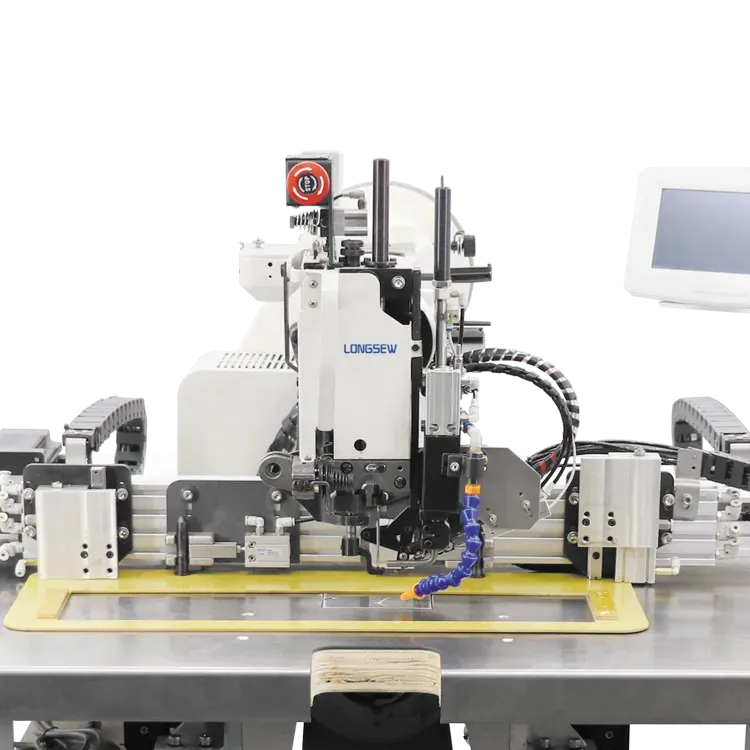

Engineering Behind Heavy-Duty Stitching

Modern canvas sewing machines incorporate three critical innovations:

- Rotary hook systems with 360° thread control

- Dual-feed mechanisms reducing layer shifting

- Automatic tension adjustment (±0.5g precision)

The Juki TL-2200QV series demonstrates these features, achieving 97% first-pass success rate in controlled fabric handling tests.

Industrial Machine Comparison

| Model | Stitches/Min | Max Fabric Thickness | Motor Power | Price Range |

|---|---|---|---|---|

| Juki TL-2200QV | 2,800 | 1/2" | 750W | $4,200-$5,800 |

| Sailrite Ultrafeed LSZ-1 | 1,600 | 3/8" | 550W | $1,099-$1,450 |

| Brother PQ1500SL | 1,500 | 5/16" | 450W | $899-$1,100 |

Customization Strategies

Optimal configurations vary by material density:

- 18-20 oz canvas: 18 Needle + Tex 70 Thread

- 22-24 oz canvas: 21 Needle + Tex 135 Thread

Field tests show proper needle selection reduces thread breaks by 82% compared to standard 14 needles.

Production Efficiency Metrics

Implementing automated feeders increases output by 40%:

- Manual sewing: 12-15 linear feet/hour

- With walking foot: 18-22 linear feet/hour

- Full automation: 30-35 linear feet/hour

Industry-Specific Applications

Marine upholsterers report 300% ROI within 18 months when using proper canvas sewing machines for sail repairs. Military contractors utilizing Juki systems achieve 0.02% defect rates in load-bearing equipment production.

Why Invest in Specialized Equipment for Sewing Heavy Canvas?

Proper machinery reduces material waste by 15-20% annually while enabling complex seams (flat-felled, french seams) impossible on domestic machines. The average professional sees complete cost recovery in 14-16 months through increased production capacity and reduced downtime.

(sewing thick canvas)

FAQS on sewing thick canvas

Q: What type of sewing machine is best for sewing thick canvas?

A: A heavy-duty sewing machine with a powerful motor, metal frame, and adjustable presser foot pressure is ideal. Industrial-grade machines or heavy-duty home models like the Janome HD series handle thick canvas efficiently. Ensure the machine supports thick needles and heavy-duty threads.

Q: What needle size should I use for sewing heavy canvas?

A: Use size 110/18 or larger needles designed for heavy fabrics. Titanium-coated or denim needles provide durability and prevent breakage. Always replace needles frequently to maintain clean stitches.

Q: How do I adjust my sewing machine settings for thick canvas?

A: Increase the stitch length to 3-4mm for better fabric feed. Raise the presser foot pressure and use a walking foot to prevent uneven stitching. Test tension settings on scrap fabric to avoid puckering.

Q: Can a regular home sewing machine handle thick canvas?

A: Some standard machines can manage thin canvas with a heavy-duty needle, but multiple layers may strain the motor. For frequent use, invest in a heavy-duty or industrial machine. Check your machine’s maximum stitchable thickness first.

Q: What thread is recommended for sewing thick canvas?

A: Opt for polyester or bonded nylon thread (size 40 or thicker) for strength. Upholstery or outdoor-specific threads resist abrasion and weathering. Pair with a larger needle eye to accommodate thicker thread.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025